Multi-effect rectifying process of methanol

A multi-effect rectification and process technology, applied in the chemical industry, sustainable manufacturing/processing, preparation of organic compounds, etc., can solve problems such as high energy consumption, low methanol recovery rate, and poor product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

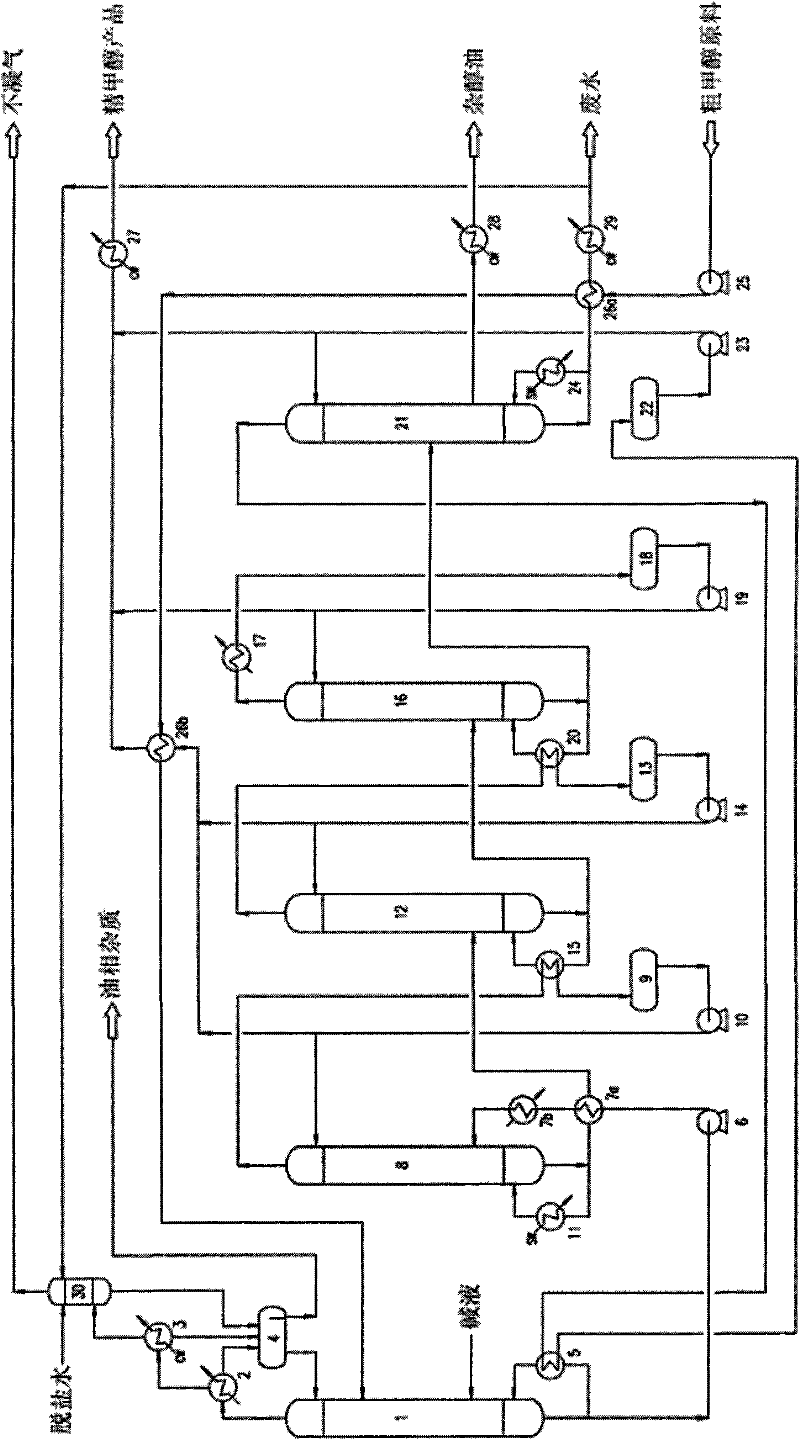

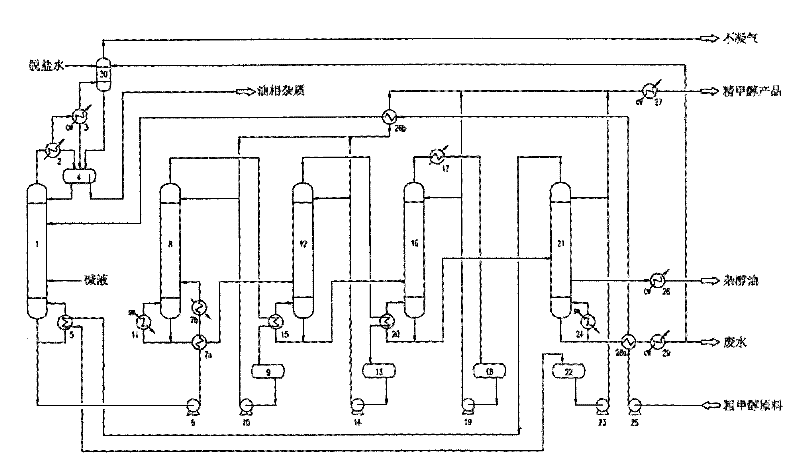

[0019] Embodiment 1, technological process of the present invention is as follows:

[0020] (1) First, the crude methanol containing impurities such as hydrogen, carbon monoxide, carbon dioxide, nitrogen, methane, dimethyl ether, methyl formate, acetone, ethanol, water, polyols and alkanes is injected into the crude methanol with the crude methanol feed pump 25 The heat exchanger 26 exchanges heat with the waste water from the recovery tower 21, the methanol products from the reflux tanks 9 and 13 on the top of the first pressurized tower 8 and the second pressurized tower 12 to 65-80°C and then enters the pre-rectification tower 1 ;

[0021] (2) The steam at the top of the pre-rectification tower 1 is cooled to about 65° C. through the primary condenser 2 at the top of the pre-column, and most of the methanol, water and a small amount of organic impurities are condensed and sent to the reflux tank 4 at the top of the pre-column. Reflux, through the first-stage condenser 2 at...

Embodiment 2

[0026] Embodiment 2. One set of 600,000 tons / year methanol rectification device adopts the methanol multi-effect rectification process flow in embodiment 1, and the pre-rectification tower, washing tower, pressurization tower I and pressurization tower II all adopt Structured packing, valve trays are used in the lower part of the atmospheric tower and recovery tower, and structured packing is used in the rest. When the refined methanol product meets the American Standard AA standard and the methanol content in the wastewater discharged from the unit is less than 50mg / kg, the methanol recovery rate of the unit can reach more than 99.8%, the total steam consumption is about 0.699t / t refined methanol, and the cooling water The total consumption is about 3.1t / t of refined methanol. The diameter and height of the pre-distillation tower, pressurization tower I, pressurization tower II, atmospheric tower and recovery tower are: φ2800×23m, φ2800×32m, φ2800×32m, φ3400×32m and φ2200×39m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com