Light oil and wide fraction separation technology and equipment applicable to tar distillation

A technology for oil-water separation and light oil, which is applied in the field of tar distillation light oil and wide fraction separation technology and equipment, can solve the problems of heavy condensation cooling burden, thick tower diameter, large gas volume, etc., and achieve reduction of tower top reflux ratio, Effects of reduced circulation and reduced condensing cooling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

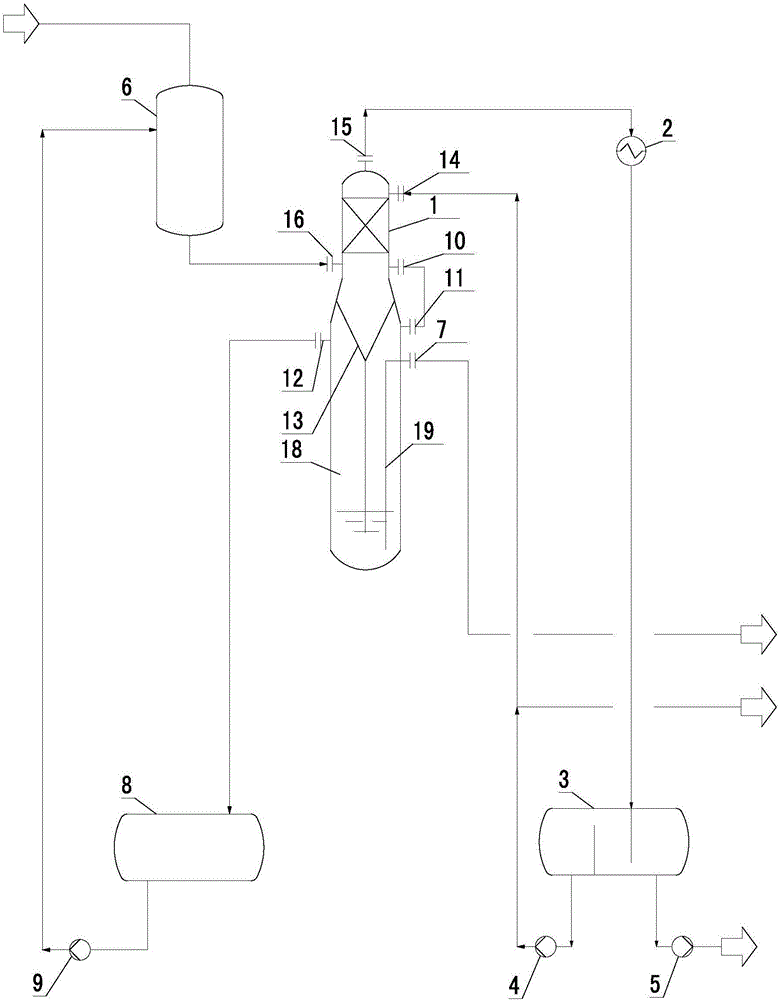

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as figure 1 Shown, a kind of light oil that is applicable to tar distillation and wide fraction separation process, this process comprises the following steps:

[0026] 1) light oil and wide fraction gas mixture enters the quenching tower 6 for rapid cooling;

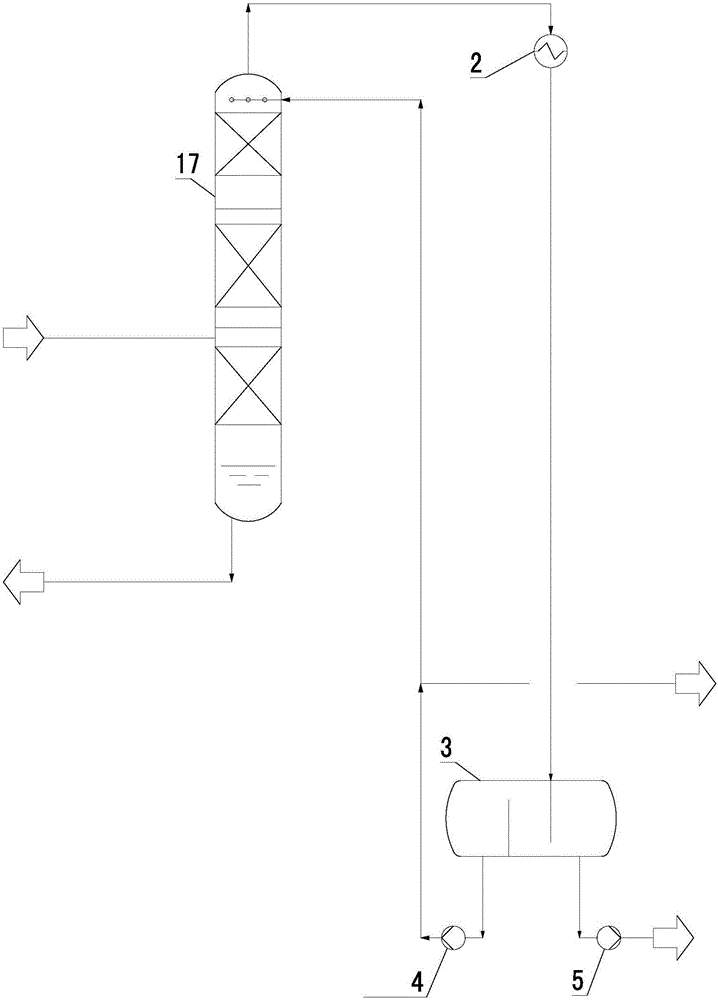

[0027] 2) The gas-liquid mixture after cooling enters the distillation tower, and the distillation tower is composed of an upper rectification tower 1 and a lower oil-water separation zone 18, and the rectification tower 1 and the oil-water separation zone 18 are separated by funnel 13 and condensed to obtain The liquid phase enters the bottom of the kettle-type tower in the lower oil-water separation zone 18 through the funnel 13;

[0028] 3) After the oil-water separation in the lower oil-water separation zone 18, the water phase flows into the ammonia water tank 8 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com