Normal pressure distillation method

A technology of atmospheric distillation and atmospheric tower, applied in hydrocarbon distillation, petroleum industry, etc., can solve the problems of high material consumption, high energy consumption, increased condensation cooling load at the top of the tower, and more sewage, so as to reduce the energy consumption of the device and reduce cooling Load and emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

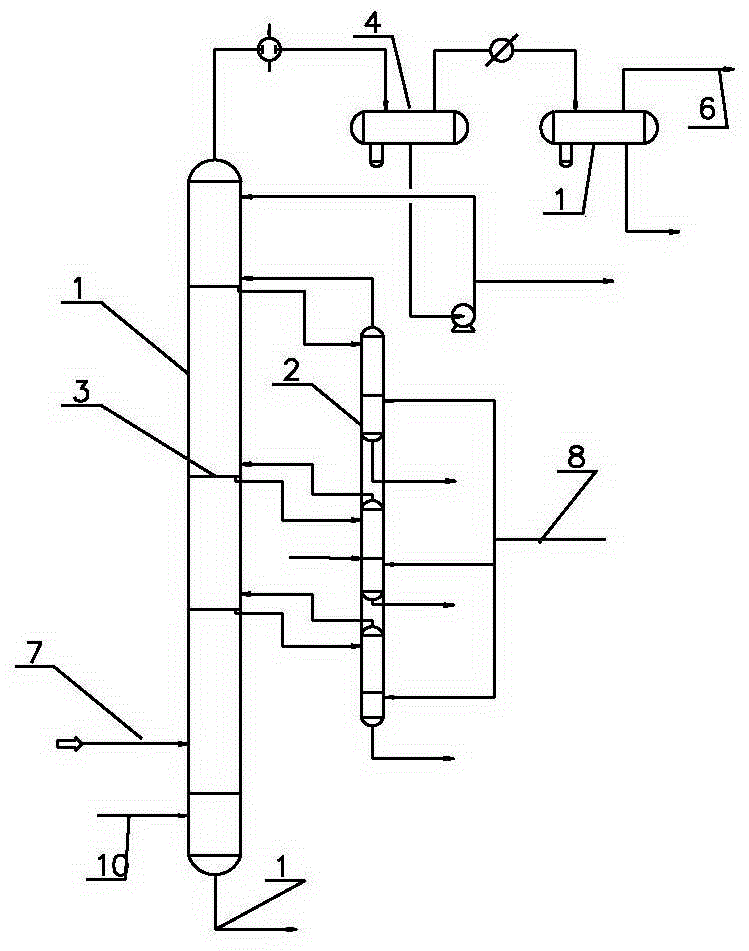

Image

Examples

Embodiment 1

[0025] Embodiment 1 (prior art)

[0026] The processing capacity of the atmospheric distillation tower is 874330kg / h, the raw material is the initial bottom oil, and the obtained atmospheric residue is 560850kg / h, the stripping steam used in the stripping section of the atmospheric distillation tower product is 700kg / h, and the stripping atmospheric tower side line Product, the stripping steam used in the atmospheric residue stripping tower is 7000kg / h, and the total heat at the top of the tower is 681×10 4 kCal / h, the amount of sewage discharged from the top of the tower is 7700kg / h.

Embodiment 2

[0027] Embodiment 2 (the present invention)

[0028] The processing capacity of the atmospheric distillation tower is 874330kg / h, the raw material is primary bottom oil, and the obtained atmospheric residue is 560850kg / h. The stripping section of the atmospheric distillation tower uses non-condensable gas for stripping, and the non-condensable gas used is the gas, its main composition is C 1 、C 2 Gas, gas volume is 700kg / h, 7000kg / h non-condensable gas used for atmospheric residue stripping, accounting for 1.25% by weight of atmospheric residue, total heat at the top of the tower is 355×10 4 kCal / h. The non-condensable gas used is system dry gas (mainly composed of C 1 ~C 2 ), the present invention saves 0.3MPa steam 7700kg / h compared with the existing device, and the tower top reduces sewage discharge by 7700kg / h. All the dry gas at the top of the tower is recovered for reuse. Steam alone can save 7.7 million yuan of capital per year.

Embodiment 3

[0029] Embodiment 3 (the present invention)

[0030]The processing capacity of the atmospheric distillation tower is 874330kg / h, the raw material is primary bottom oil, and the obtained atmospheric residue is 560850kg / h. The product stripping section of the atmospheric distillation tower uses non-condensable gas for stripping. gas, its main composition is C 1 、C 2 Gas, the gas volume is 8200kg / h, the non-condensable gas used in the atmospheric residue stripping tower is 910kg / h, accounting for 1.62% by weight of the atmospheric residue, and the total heat at the top of the tower is 415×10 4 kCal / h. The noncondensable gas used is the constant top noncondensable gas (mainly composed of C 1 ~C 4 light hydrocarbon components), and the non-condensable gas at the top of the tower is recycled. Compared with the existing device, the present invention saves 0.3MPa steam by 7700kg / h, and reduces sewage discharge by 7700kg / h from the top of the tower. Steam alone can save 7.7 milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com