Method for separating 3, 4-dichloronitrobenzene crystallization mother liquor through extractive distillation

A technology of dichloronitrobenzene and crystallization mother liquor, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of increased tar, low oil consumption, low zeolite adsorption capacity, small processing capacity, etc. The effect of small equipment investment, low implementation difficulty and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

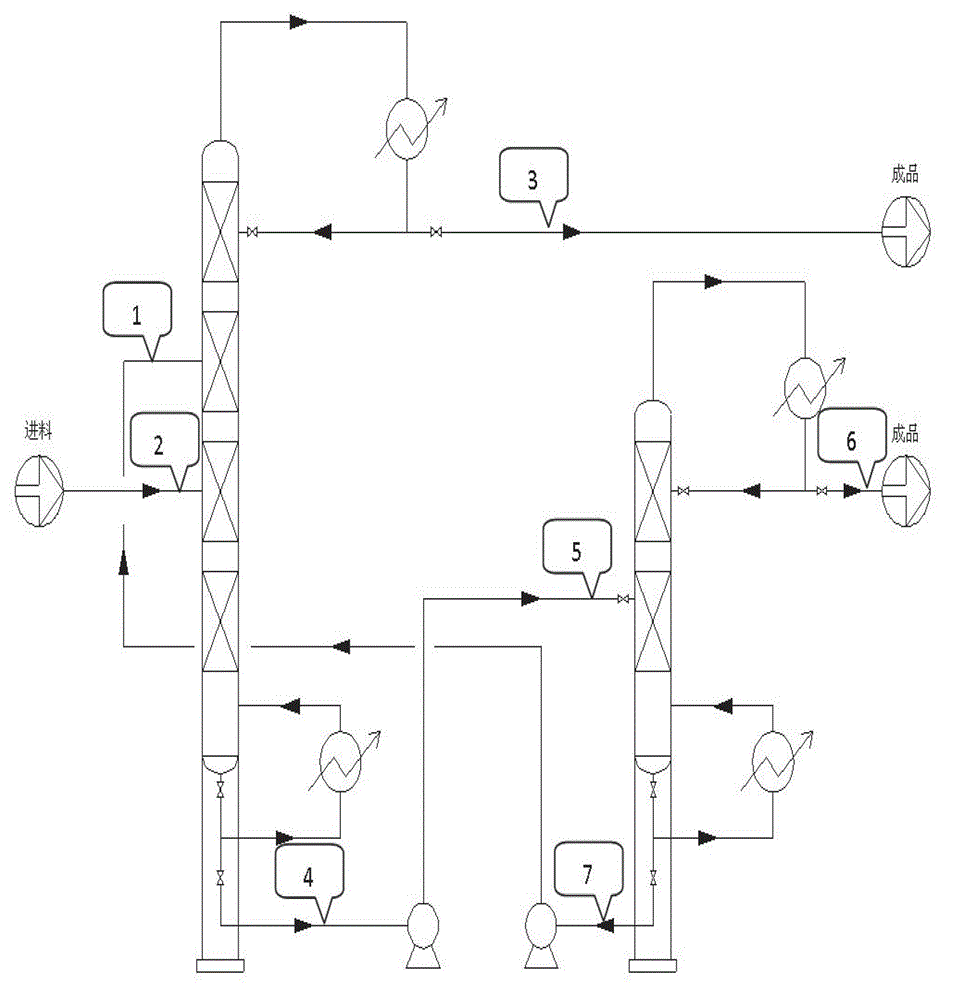

[0025] Such as figure 1 The separation process shown is composed of an extractive distillation tower and a solvent recovery tower. The extractive distillation tower has 50 theoretical plates (counted from top to bottom). Triethylene glycol is selected as the extraction agent. From the fifth block (from top to bottom), Bottom number) the theoretical plate enters the extractive distillation column, the flow rate is 100kg / h, the low oil enters from the 25th theoretical plate, the low oil composition is 3,4-DCNB 67.2% 2,3-DCNB 32.8%, low oil The flow rate is 50kg / h. The vacuum at the top of the extractive distillation tower is 10mmHg, and the reflux ratio is 2.0:1. At this time, the temperature at the top of the tower is 122.2°C, and the temperature at the bottom of the tower is 182.8-184.7°C.

[0026] The solvent recovery tower has 20 theoretical plates, and the material from the extractive distillation column comes out of the tower tank and enters from the fifth theoretical pla...

Embodiment 2

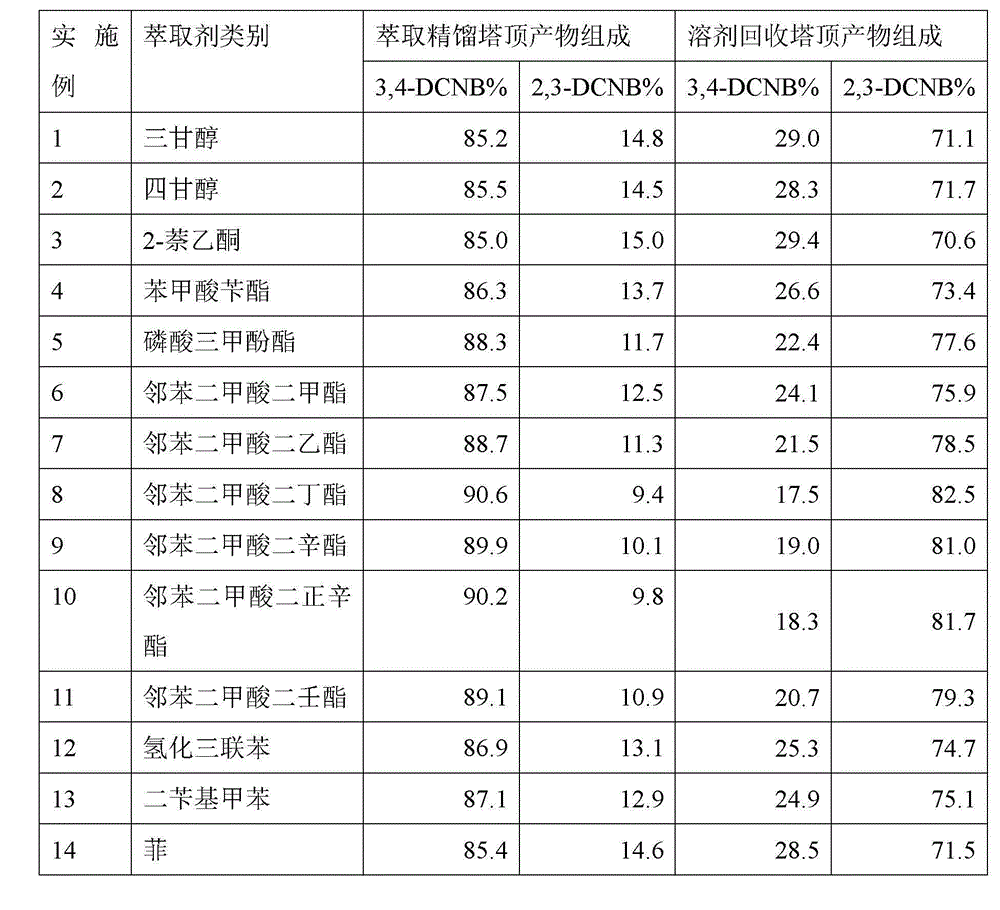

[0028]Other conditions are the same as in Example 1, tetraethylene glycol is selected as the extractant, the temperature at the top of the extractive distillation tower is 124.8° C., and the temperature at the bottom of the tower is 188.7-193.1° C. The bottom material of the extractive distillation tower enters the solvent recovery tower. The operating pressure of the solvent recovery tower is 7mmHg, the reflux ratio is 1.5:1, the temperature of the top of the tower is 127.0°C, and the temperature of the bottom of the tower is 184.1-191.5°C. The product in the bottom of the solvent recovery tower is returned to the extractive distillation tower for recycling. Under this condition, the gas chromatography analysis results of the extractive distillation tower and the solvent recovery tower top product are shown in Table 1.

Embodiment 3

[0030] Other conditions are the same as in Example 1, 2-naphthyloethanone is selected as the extractant, the temperature at the top of the extractive distillation tower is 124.7°C, and the temperature at the bottom of the tower is 186.5-190.1°C. The bottom material of the extractive distillation tower enters the solvent recovery tower. The operating pressure of the solvent recovery tower is 7mmHg, the reflux ratio is 2.0:1, the temperature at the top of the tower is 126.9°C, and the temperature at the bottom of the tower is 184.3-187.5°C. The product in the bottom of the solvent recovery tower is returned to the extractive distillation tower for recycling. Under this condition, the gas chromatography analysis results of the extractive distillation tower and the solvent recovery tower top product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com