Recovery technology of methyl alcohol production waste heat

A methanol and waste heat technology, which is applied in the chemical industry, sustainable manufacturing/processing, preparation of organic compounds, etc., can solve the problem of high cost of recycling process, achieve the effect of reducing equipment investment, high thermal energy utilization rate, and low thermal energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

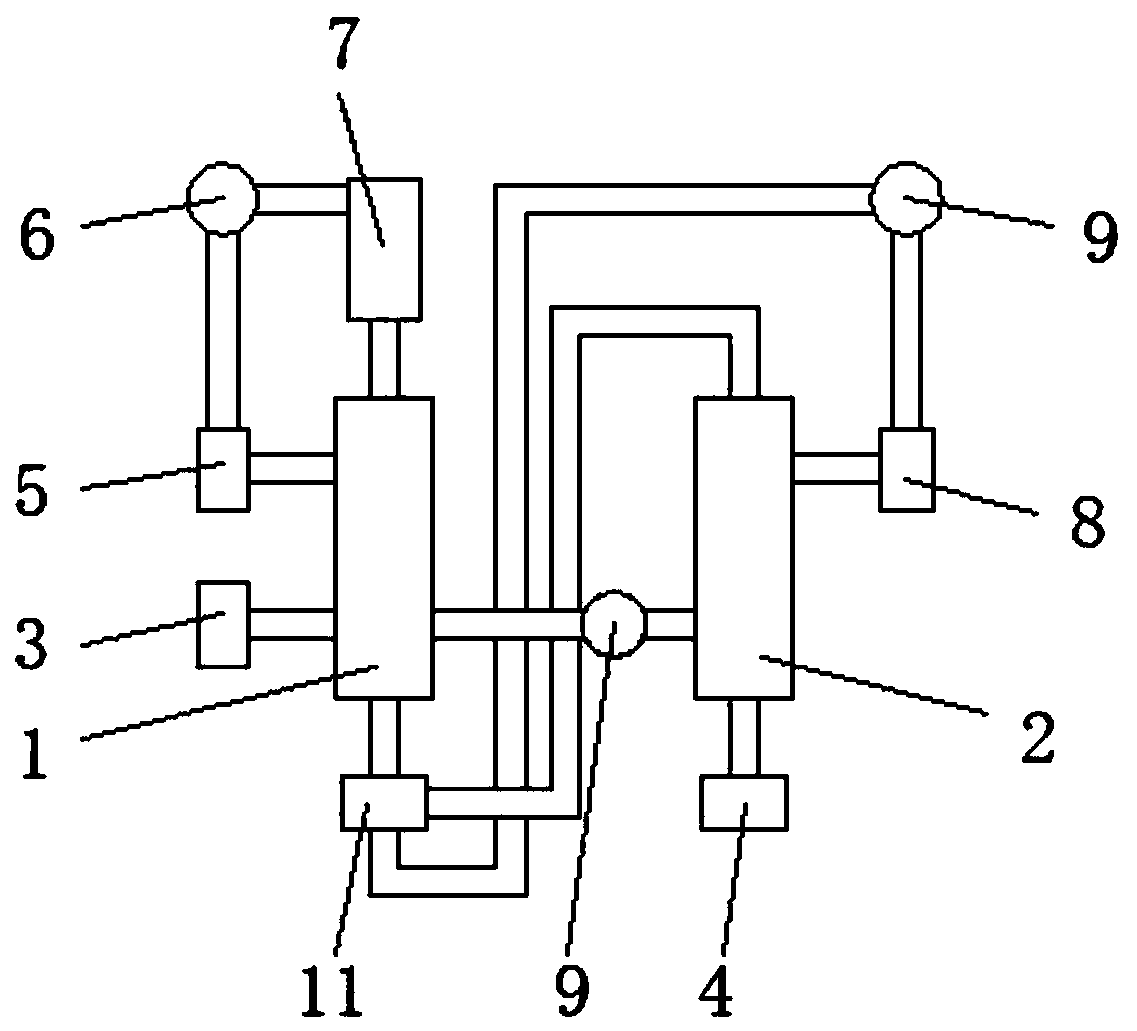

[0024] A process for recovering waste heat from methanol production, comprising an atmospheric tower 1 and a pressurized tower 2, the left side of the atmospheric tower 1 communicates with the right side of the pressurized tower 2 through a pipeline, and the bottom of the left side of the atmospheric tower 1 communicates with the pipeline There is a preheater 3, and the bottom of the pressurized tower 2 is connected with a heater 4 through a pipeline. The specific recovery process includes the following steps: Step 1: Divide the methanol raw material into two raw materials with a mass ratio of 1.5:1, and divide the 1.5:1 The first part of methanol raw material is added in atmospheric tower 1 and carried out atmospheric rectification, obtains the tower bottom liquid of atmospheric tower 1 methanol vapor and atmospheric tower 1; Step 2: the tower bottom liquid of atmospheric tower 1 and 1.5: The second part of methanol raw material in 1 is respectively added to pressurized tower ...

Embodiment 2

[0026] In embodiment 1, add following operation:

[0027] The methanol raw material is methanol waste liquid produced in the chemical or pharmaceutical industry, and the concentration of methanol in the methanol raw material is not less than 50%.

[0028] A process for recovering waste heat from methanol production, comprising an atmospheric tower 1 and a pressurized tower 2, the left side of the atmospheric tower 1 communicates with the right side of the pressurized tower 2 through a pipeline, and the bottom of the left side of the atmospheric tower 1 communicates with the pipeline There is a preheater 3, and the bottom of the pressurized tower 2 is connected with a heater 4 through a pipeline. The specific recovery process includes the following steps: Step 1: divide the methanol raw material into two raw materials with a mass ratio of 2:1, and divide the 2:1 The first part of methanol raw material is added in atmospheric tower 1 and carried out atmospheric rectification, ob...

Embodiment 3

[0030] In embodiment 2, add following operation:

[0031] The top of the left side of the atmospheric tower 1 is connected with the atmospheric tower reflux tank 5 through the pipeline, the top of the atmospheric tower reflux tank 5 is connected with the atmospheric tower reflux pump 6 through the pipeline, and the right side of the atmospheric tower reflux pump 6 is connected with the normal pressure tower reflux pump 6 through the pipeline. Atmospheric tower condenser 7 is arranged, and the bottom of atmospheric tower condenser 7 is communicated with the top of atmospheric tower 1 by pipeline, and the right side of atmospheric tower 1 is communicated with suction pump 9 by pipeline, and the right side of suction pump 9 It communicates with the left side of the pressurization tower 2 through a pipeline.

[0032] A process for recovering waste heat from methanol production, comprising an atmospheric tower 1 and a pressurized tower 2, the left side of the atmospheric tower 1 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com