Large-scale methanol multi-effect energy-saving rectifying device and process

A multi-effect rectification and methanol technology, which is applied in the field of rectification, can solve the problems of increasing the energy consumption per unit of methanol, increasing the load of the recovery tower, and increasing the reflux ratio, so as to reduce the energy consumption, reduce the reflux ratio, and reduce the effective energy. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

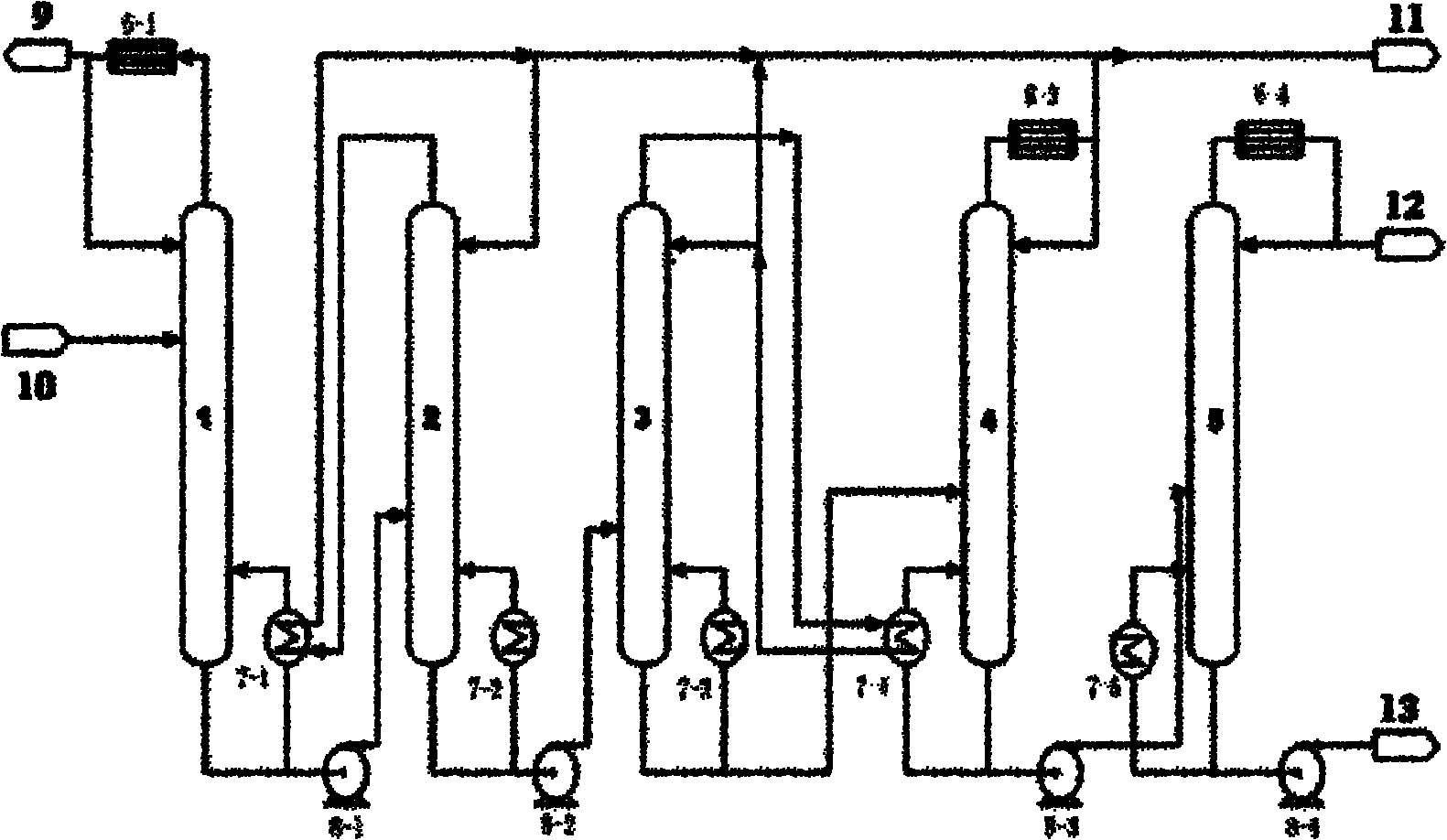

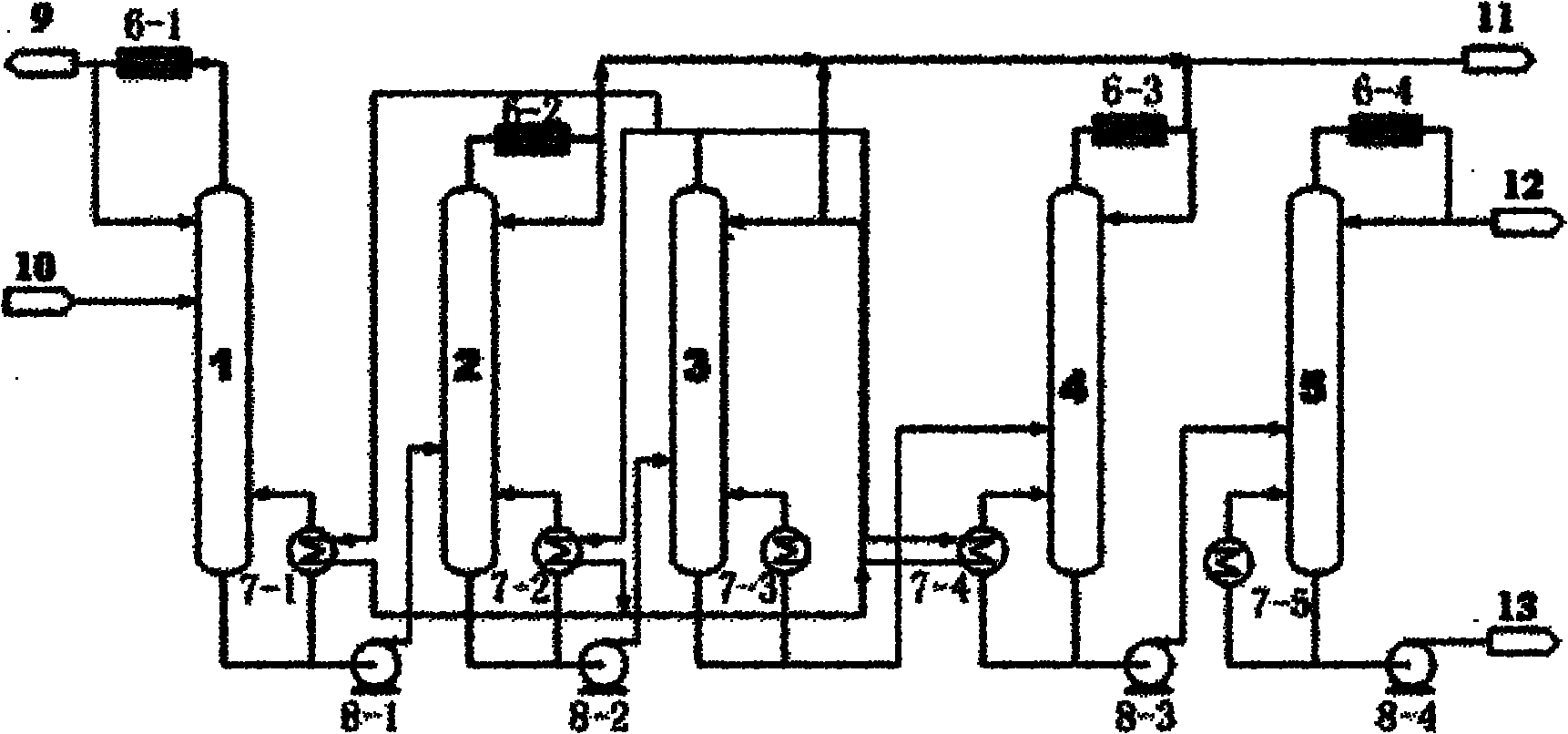

[0020] Attached below figure 1 and 2 The details of the present invention are further described through specific examples for the process flow of the present invention.

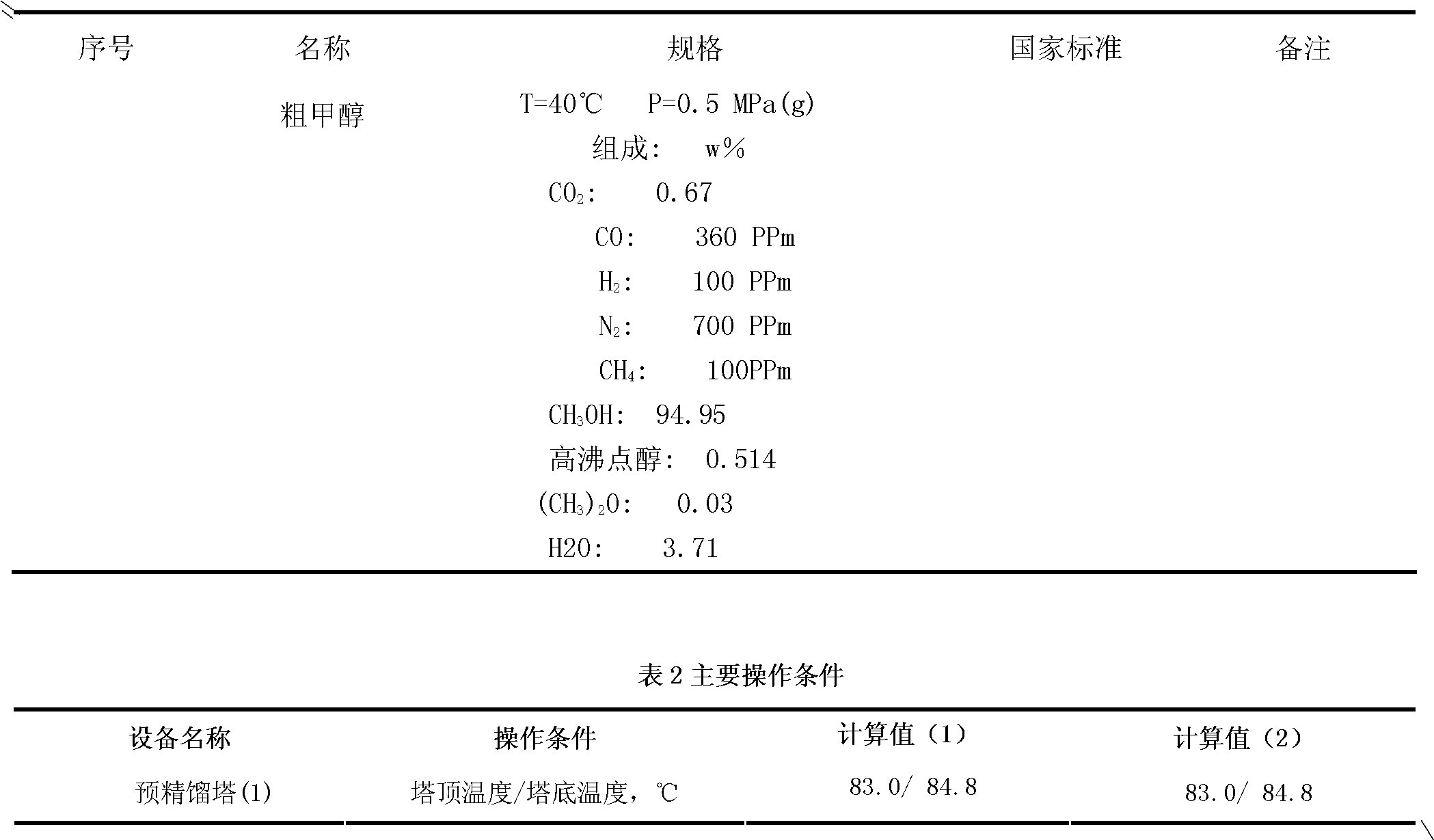

[0021] The crude methanol whose composition is shown in Table 1 is separated according to the following process:

[0022] The energy-saving process of the present invention includes two process flows, the first flow is: the crude methanol 10 enters the middle and upper part of the pre-rectification tower 1 . The top gas passes through the pre-rectification tower condenser 6-1 and the addition of process extraction water to achieve the purpose of removing light component impurities 9 and adjust the prognosis of methanol water solubility. In the middle and lower part of the tower, a NaOH aqueous solution inlet is provided to balance the pH value of methanol. The temperature at the top of the tower is 80-90°C, the temperature at the bottom of the tower is 80-90°C, the operation is under normal pressure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com