Method for separating benzene/toluene and methanol-alkylated reaction product

A technology of alkylation reaction and toluene, which is applied in the field of separation of benzene, or toluene and methanol alkylation reaction products, can solve the problem of high cost, achieve the effects of reducing corrosion, reducing process equipment requirements, and saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

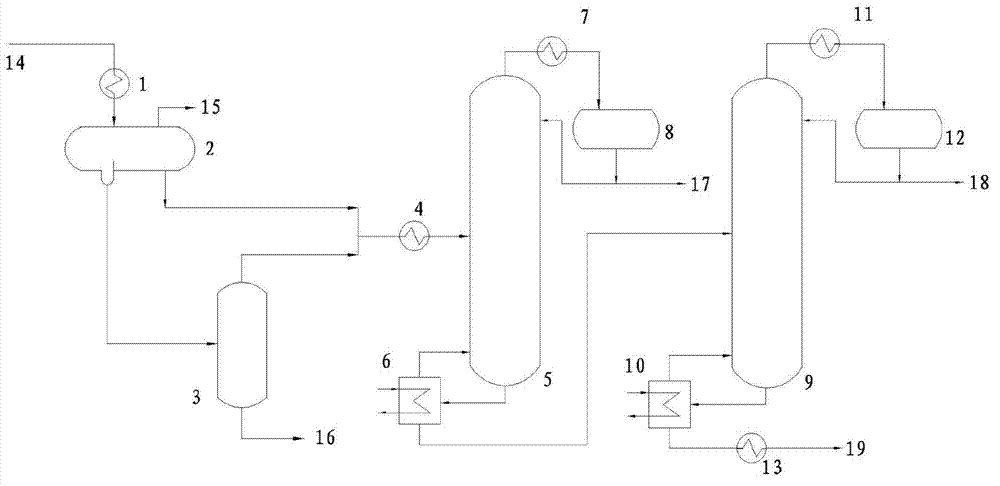

[0037] The high-efficiency oil-water separator used in the present invention is the JYF series high-efficiency oil-water separator produced by Jiangsu Asia Environmental Protection Co., Ltd. Concrete technological process of the present invention is as follows:

[0038] 1. Benzene or toluene, or the mixture of benzene and toluene and methanol alkylation reaction product (14) exits the reactor, cools down through the heat exchanger (1) and then enters the oil-water separation tank (2) for separation, and the oil phase is exchanged After the heater (4) heats up, the benzyl toluene rectifying tower (5) is removed, the water phase is removed to the high-efficiency oil-water separator (3), and the non-condensable gas (15) is discharged into the low-pressure gas pipe network.

[0039] 2. The water phase from the bottom of the oil-water separation tank (2) enters the high-efficiency oil-water separator (3) for deep separation, the oil phase is separated at the top, and the water phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com