Patents

Literature

81results about How to "Sufficient transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

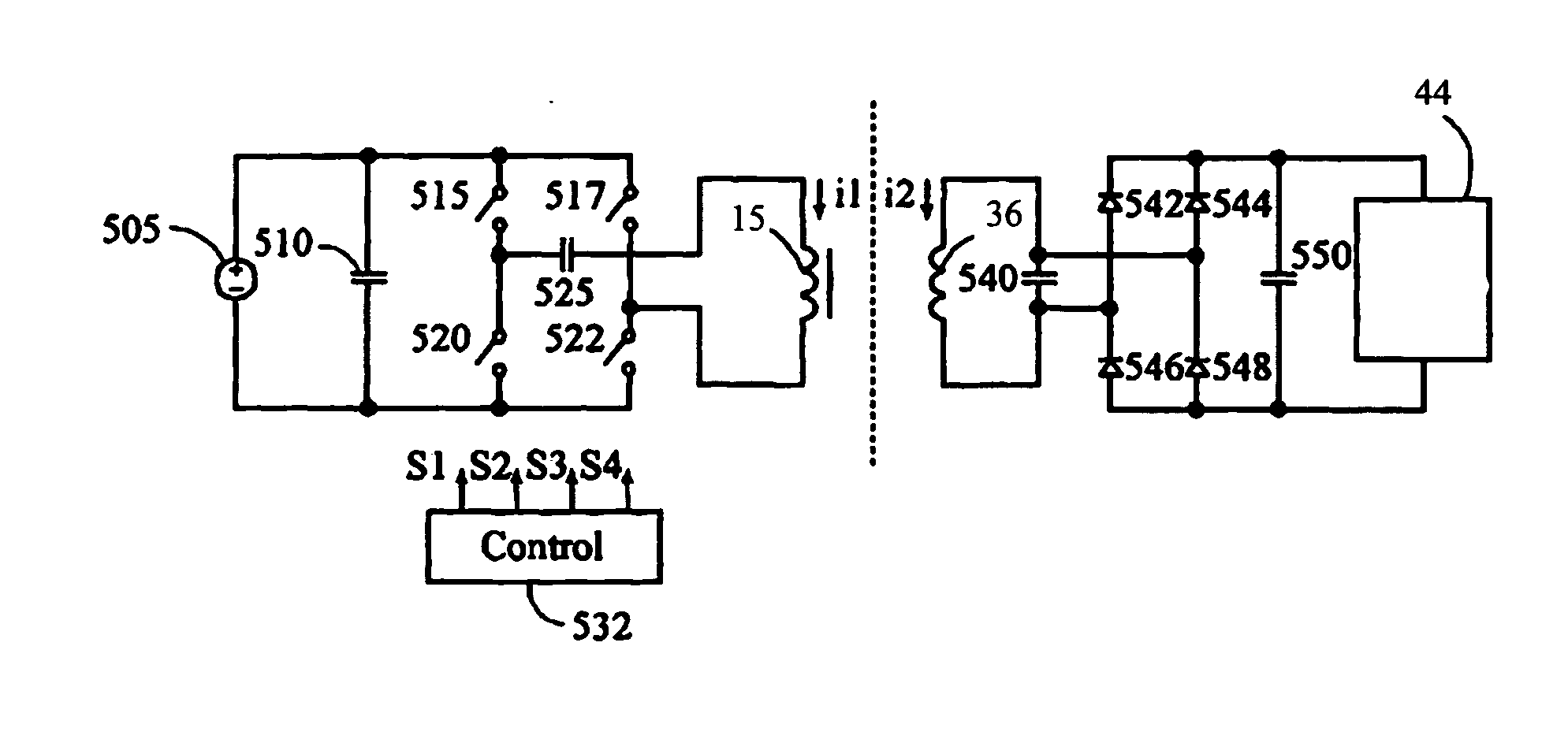

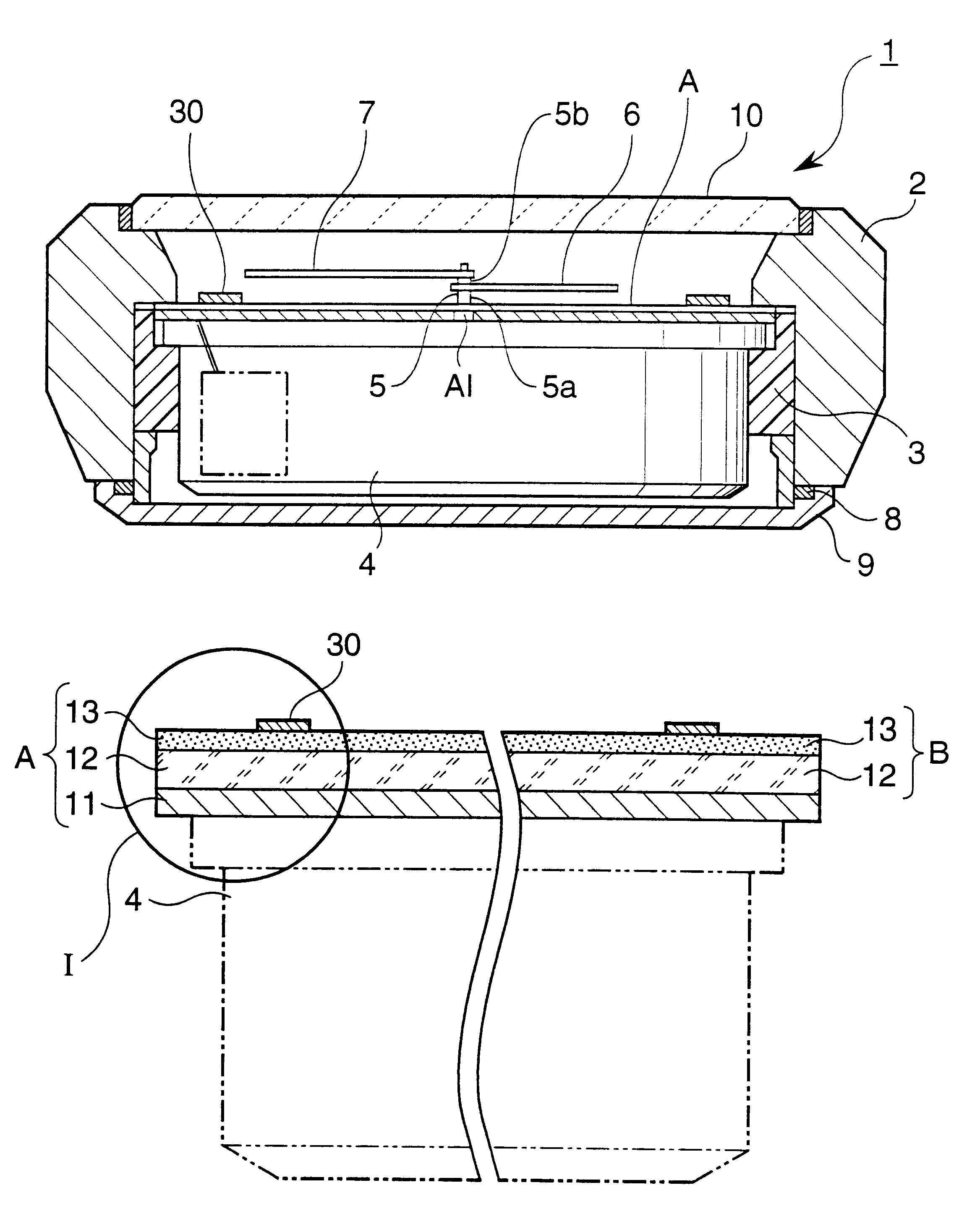

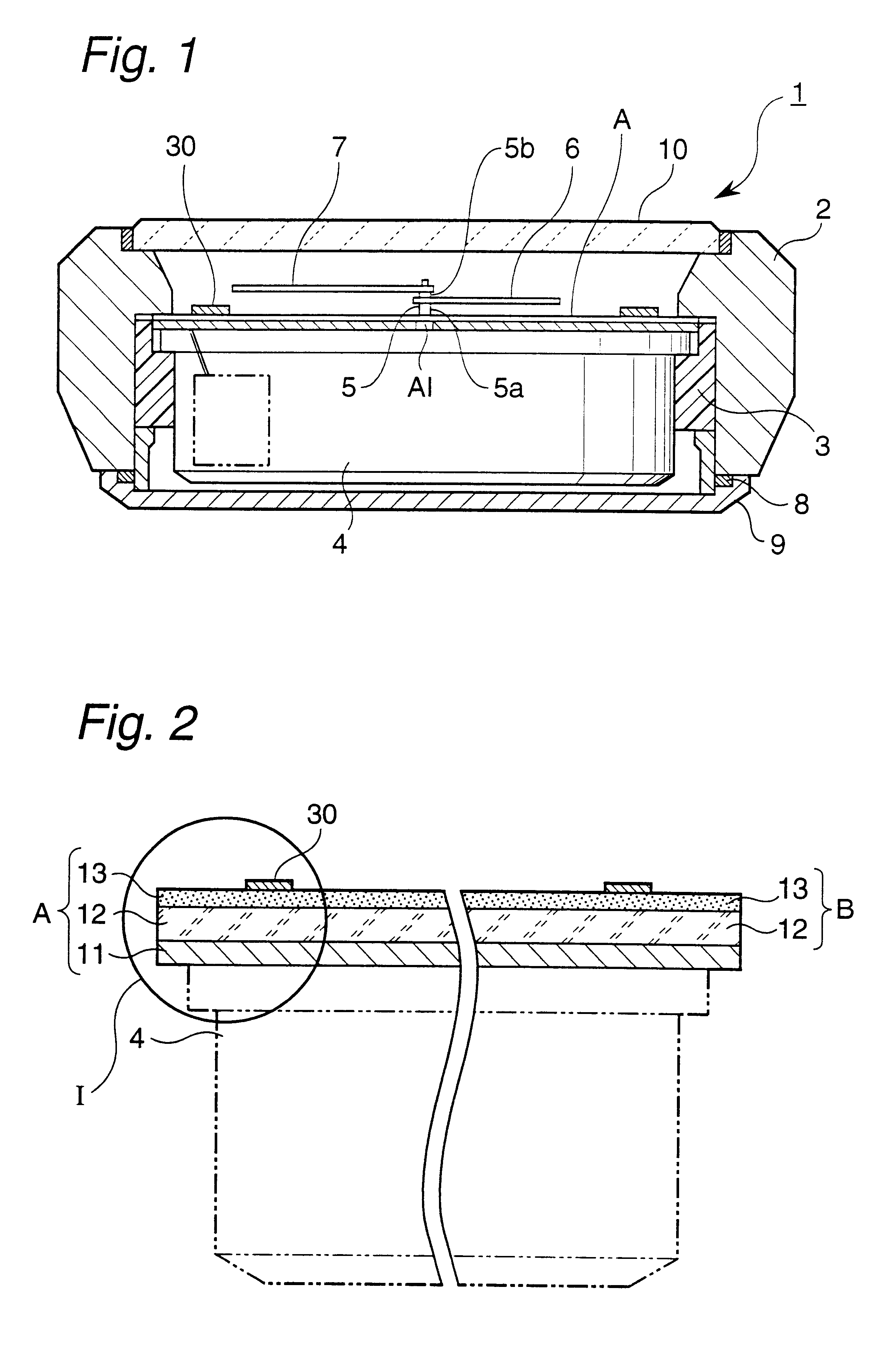

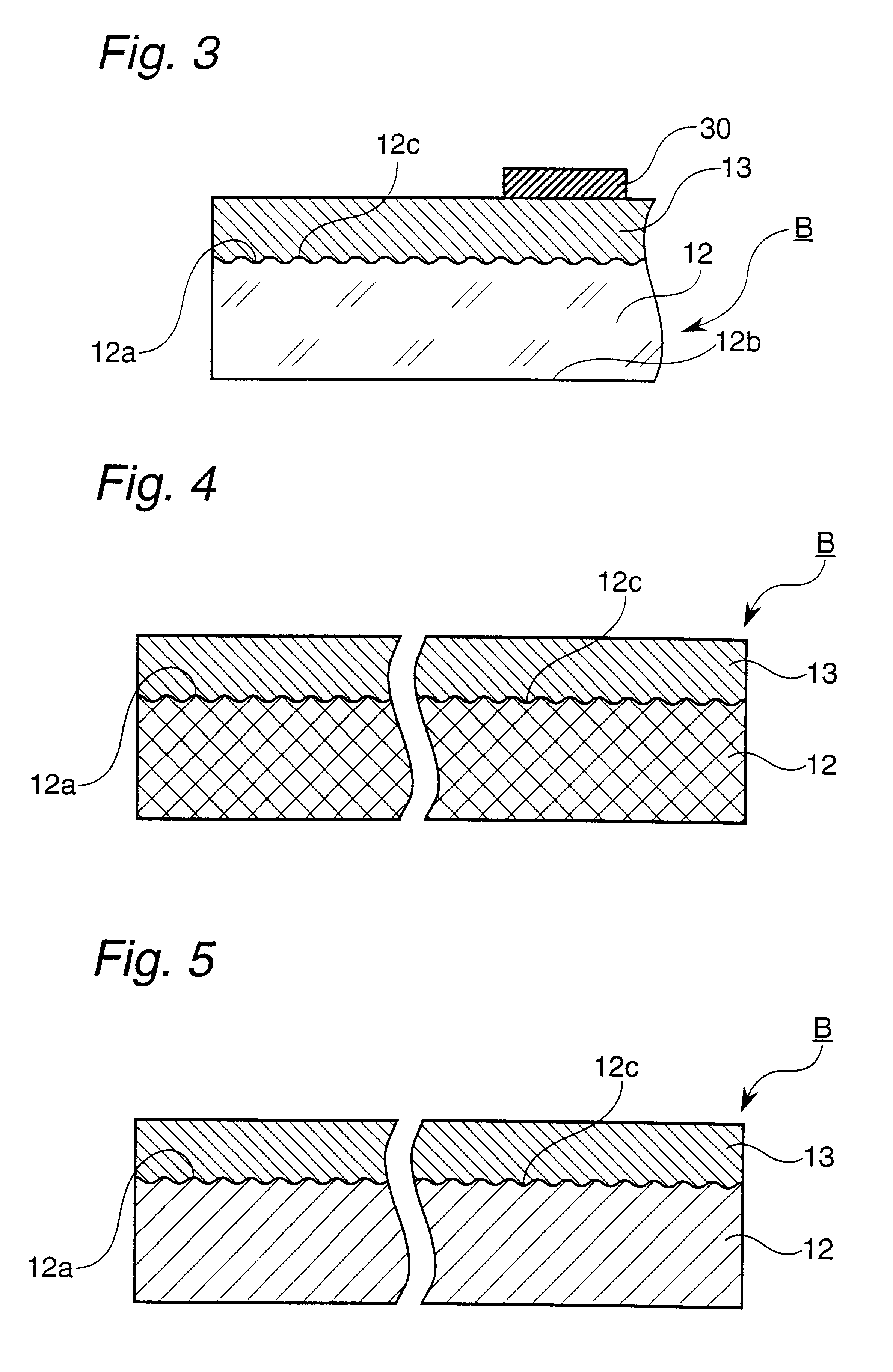

Implantable medical device with contactless power transfer housing

InactiveUS20050288743A1Minimizing surgeryMinimizing subsequent treatmentElectrotherapyElectromagnetic wave systemTransmitted powerElectrical battery

A transcutaneous recharging system for providing power to an implantable medical device comprises a primary side circuit for transmitting power in the form of magnetic flux; and a secondary side circuit integral to the implantable medical device for receiving the power transmitted from the primary side circuit and for providing the received power to recharge a battery in the implantable medical device, wherein the primary and secondary side circuits are not physically coupled. A variety of attachment configurations are disclosed for attaching and shielding the secondary circuit directly onto the housing of the implantable medical device, inclusive of flexible printed circuit coils and wire coils recessed into helical notches.

Owner:AHN IN +2

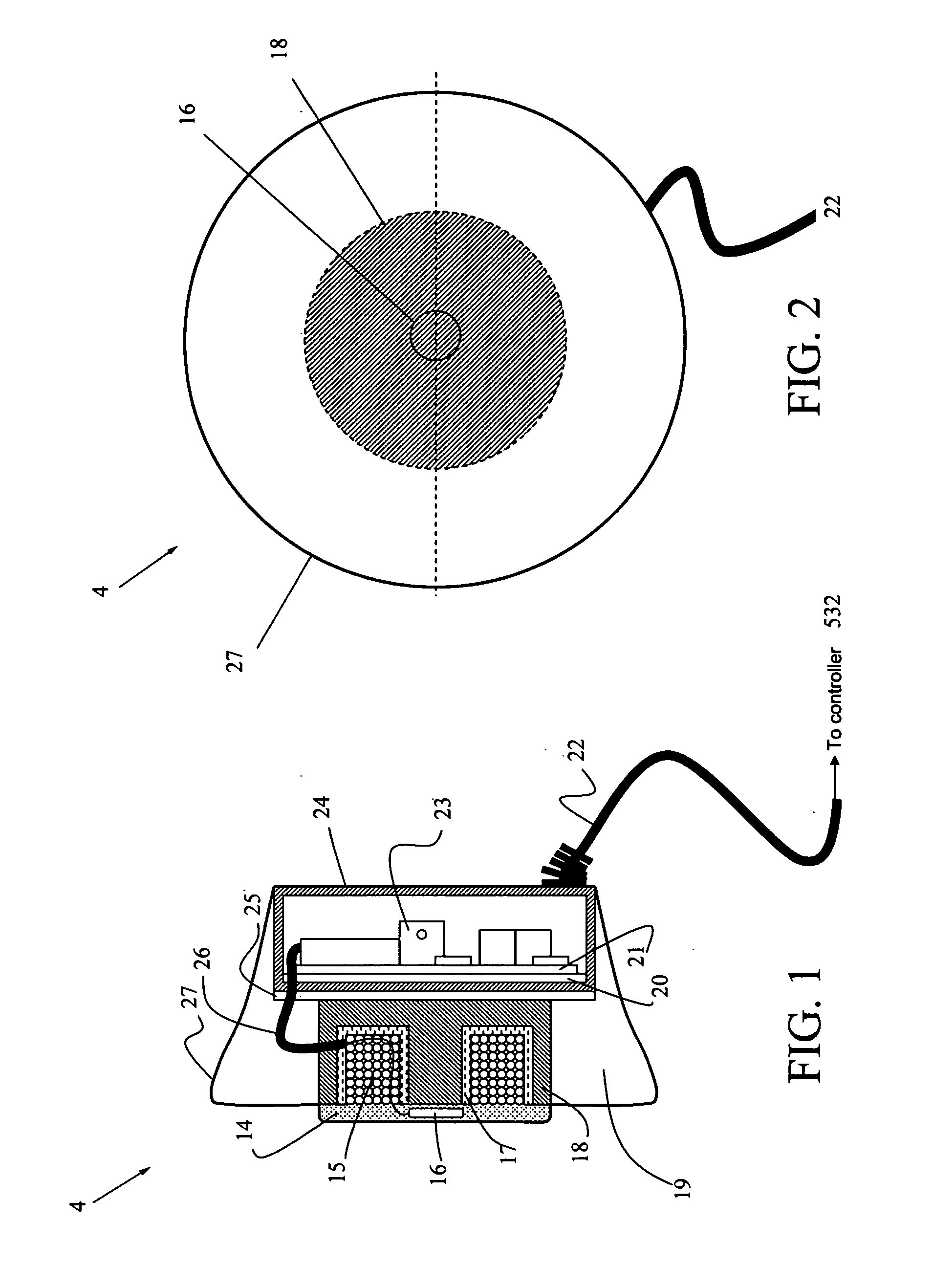

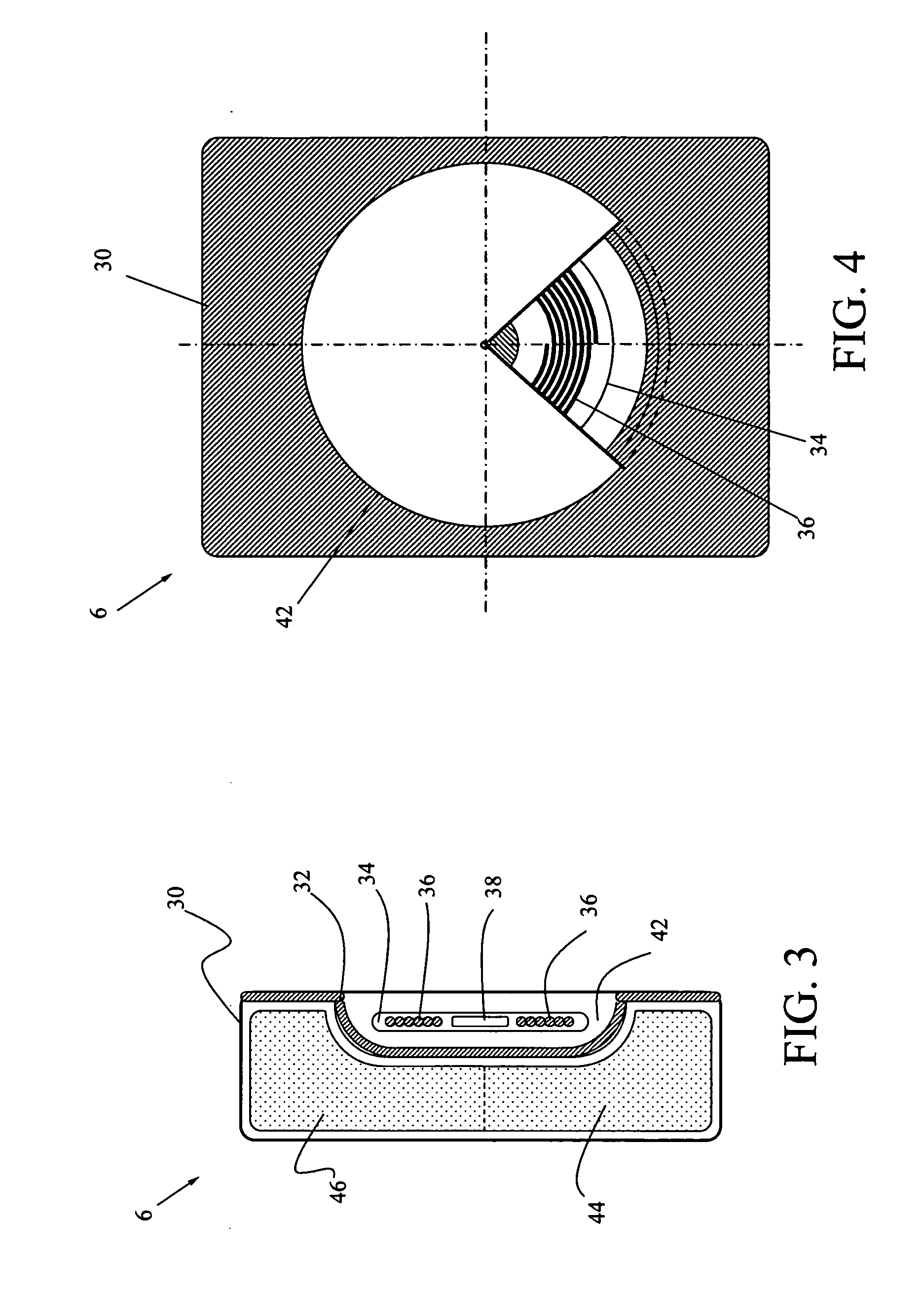

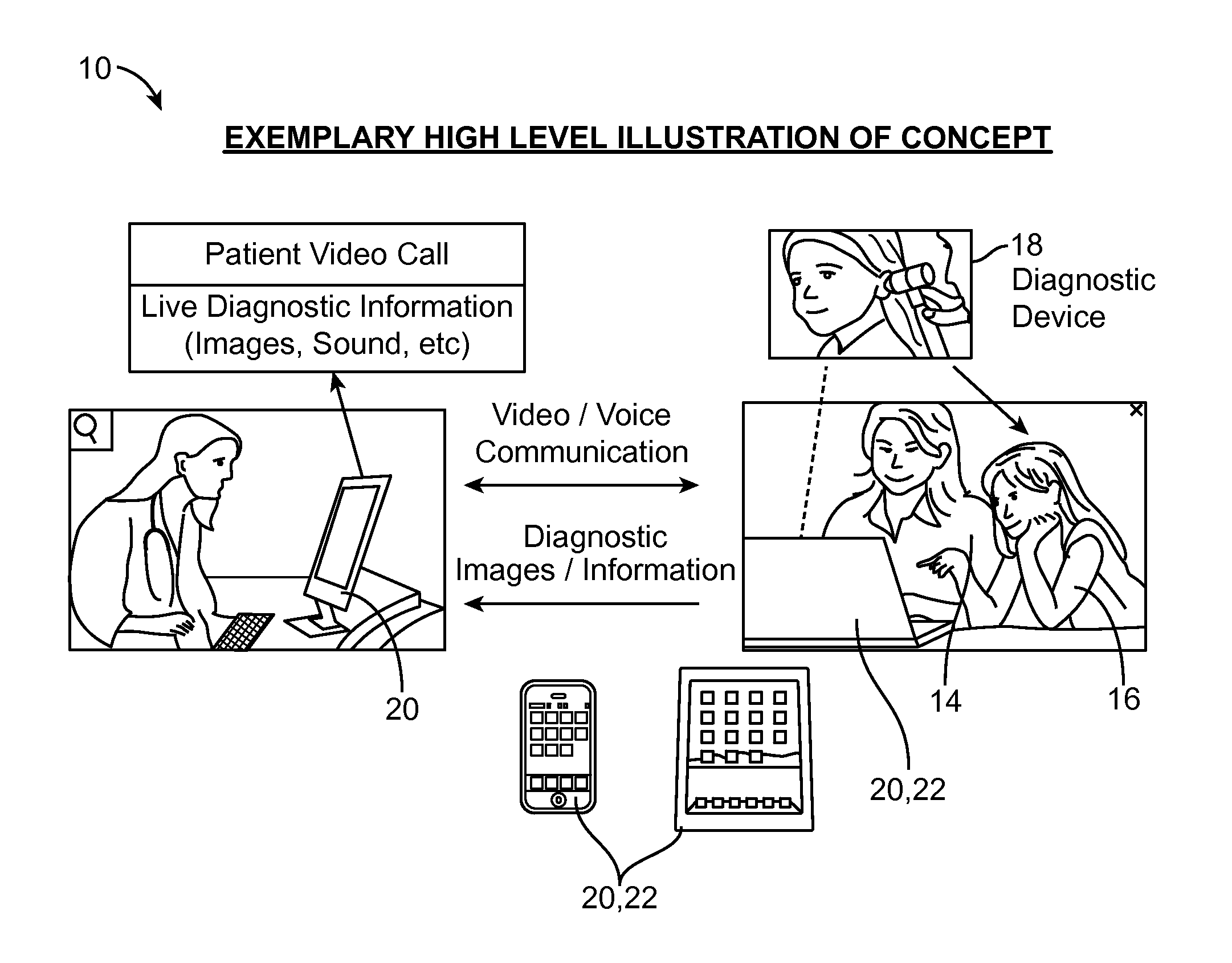

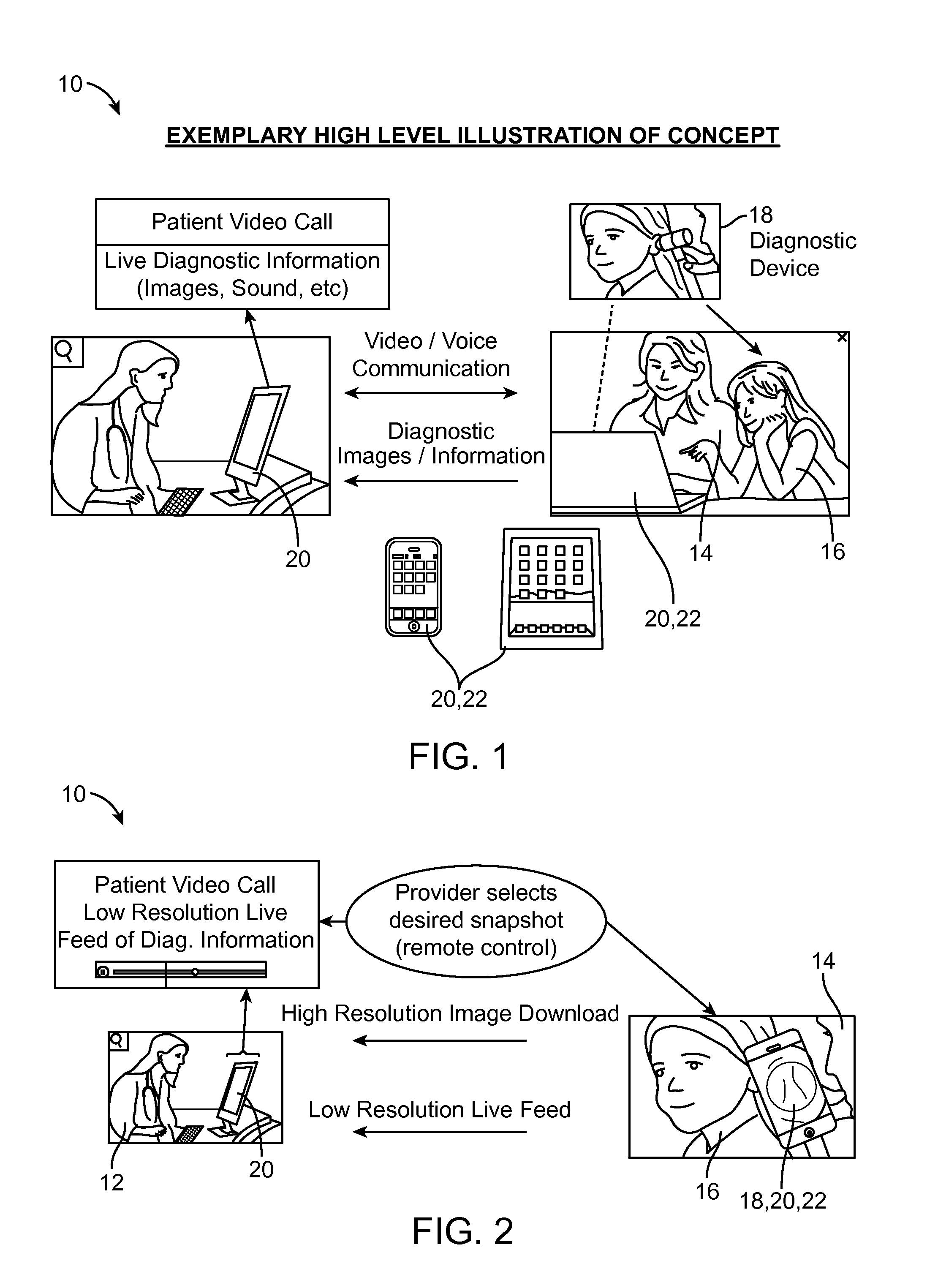

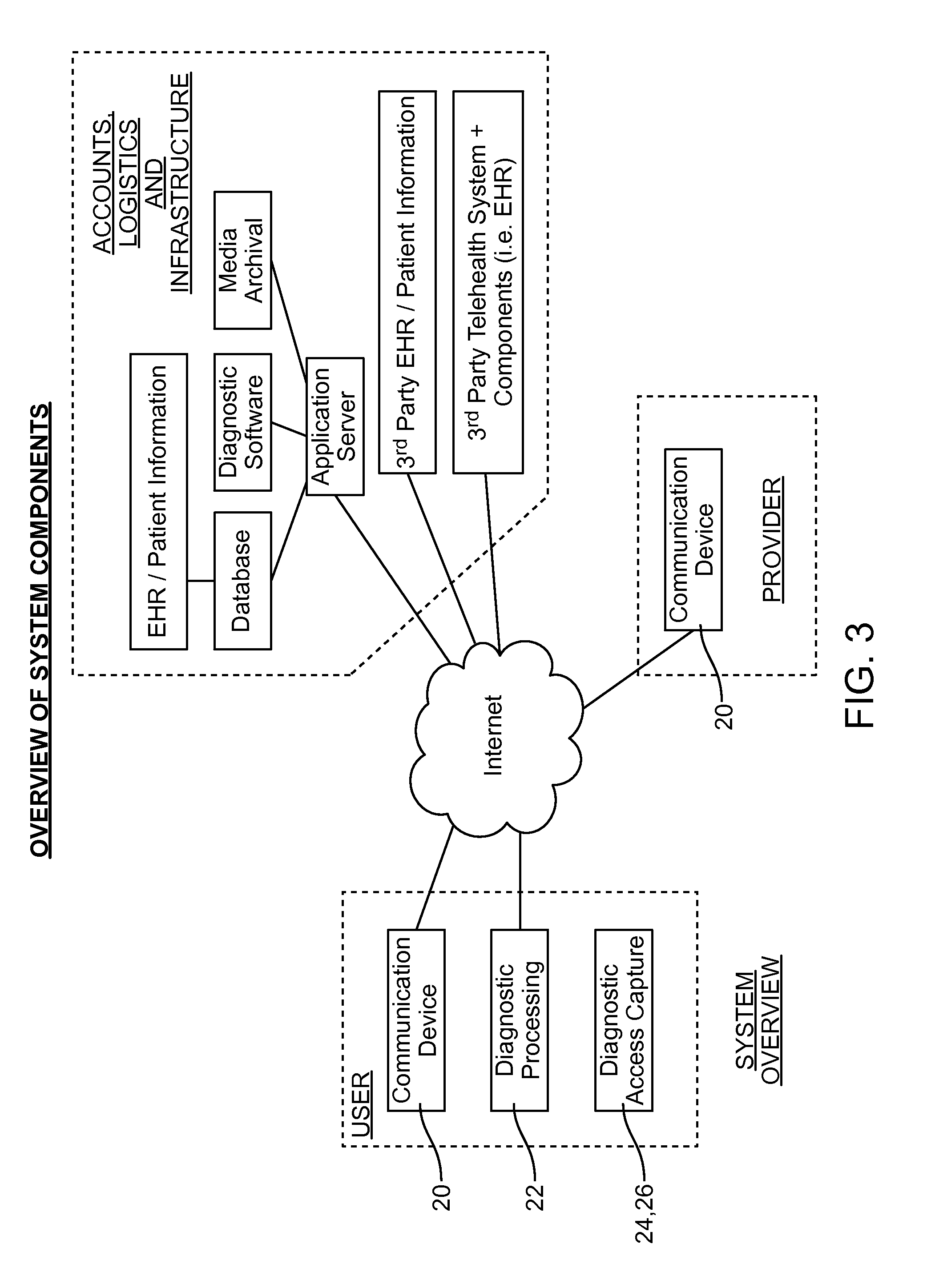

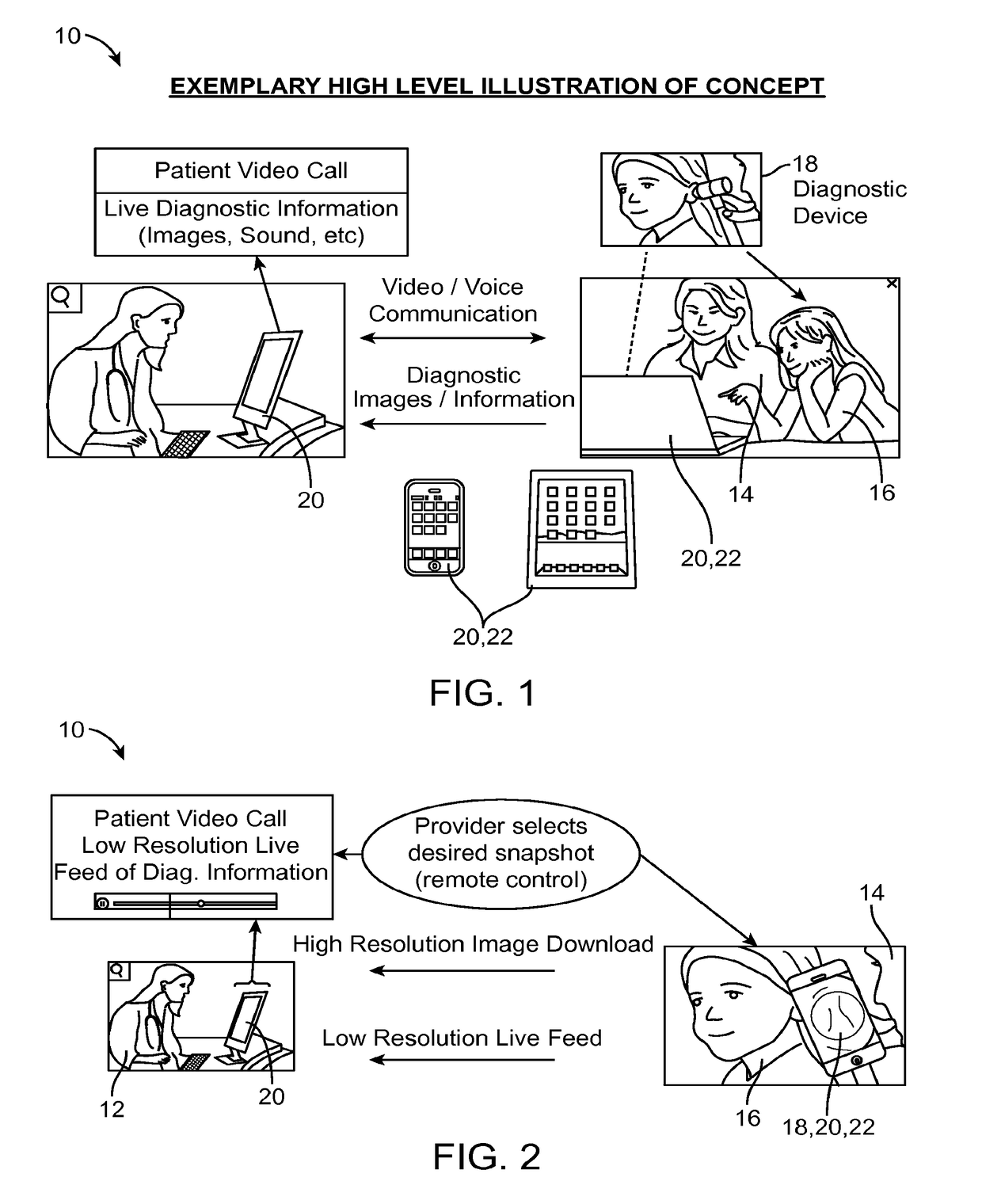

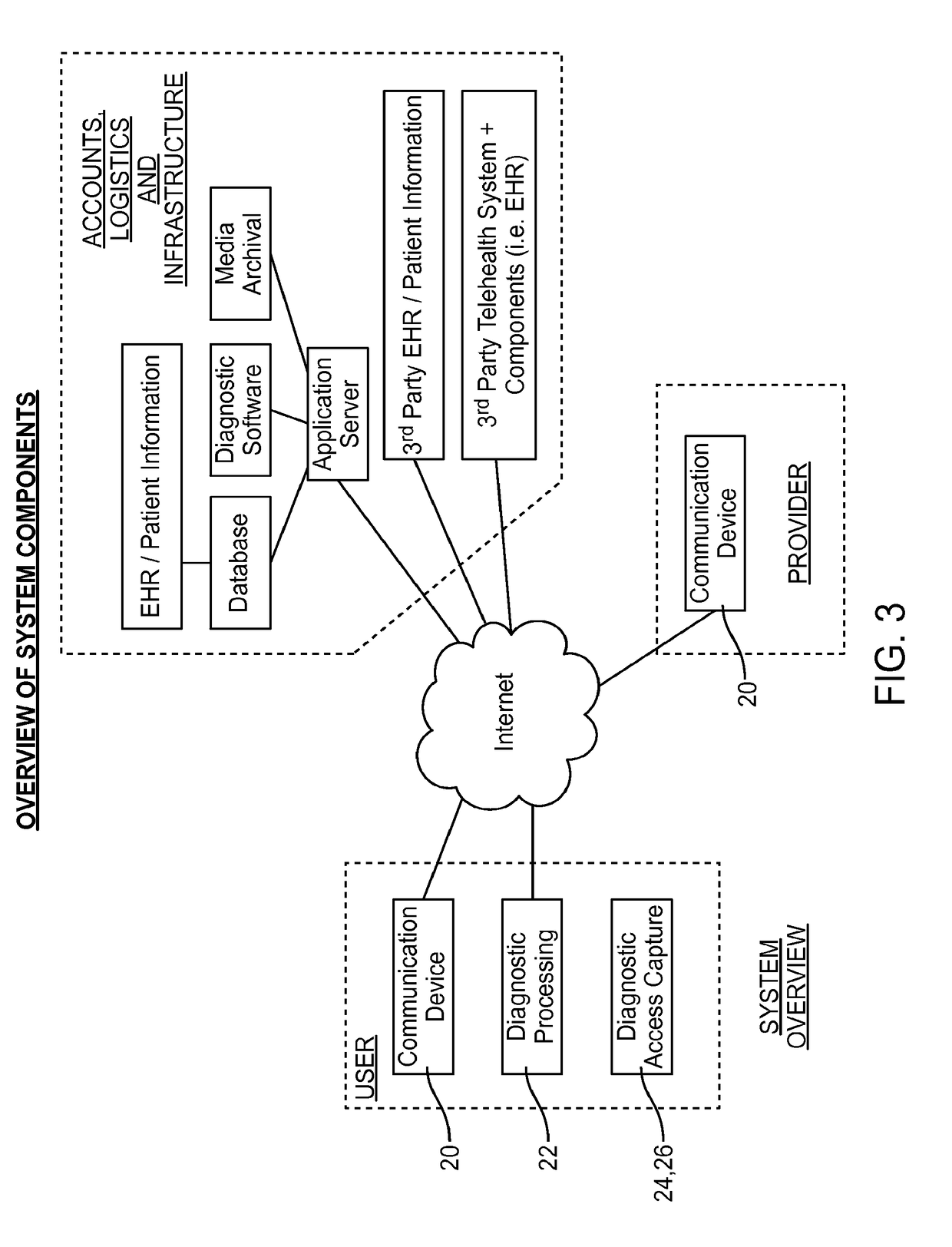

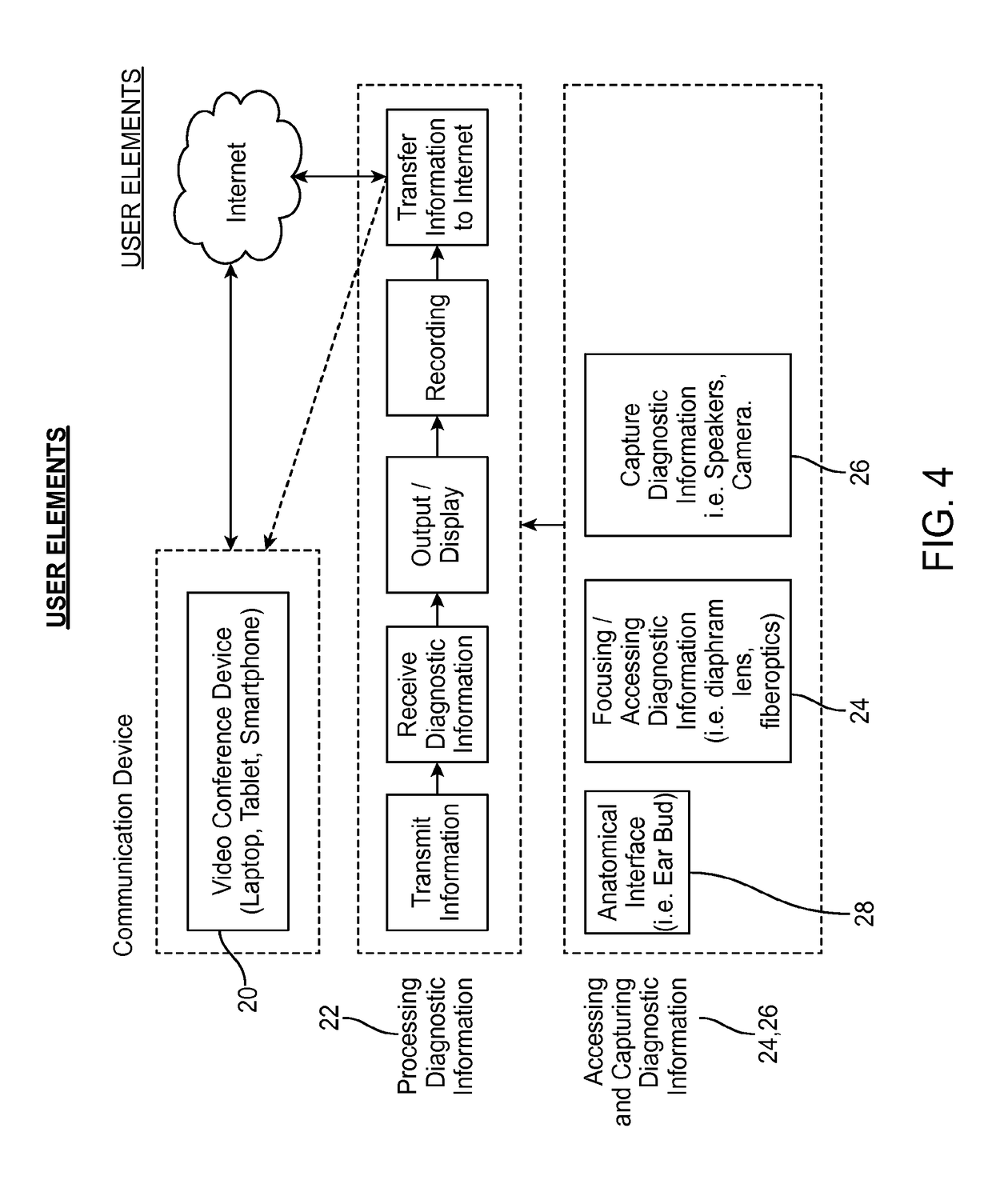

Devices, Methods and Systems for Acquiring Medical Diagnostic Information and Provision of Telehealth Services

InactiveUS20140073880A1Reduce in quantityIncrease the number ofOtoscopesStethoscopeThird partyDiagnostic information

The invention relates generally to various systems, tools and methods for acquiring diagnostic information, including medical information, for a user, transmitting the information to a remote location, assessing the information, and transmitting resulting diagnosis and treatment information to the user and / or a third party for subsequent action. The present invention provides consumer and user-friendly telemedicine systems and procedures which enable health services and / or diagnosis to be provided at a distance remotely.

Owner:BOUCHER RYAN +2

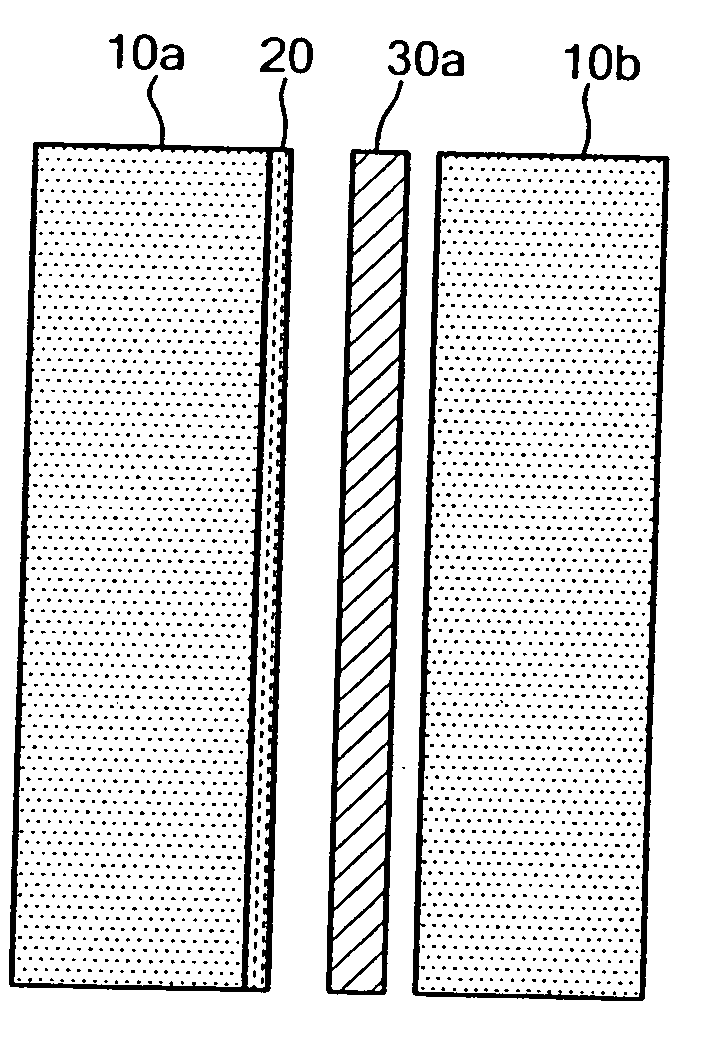

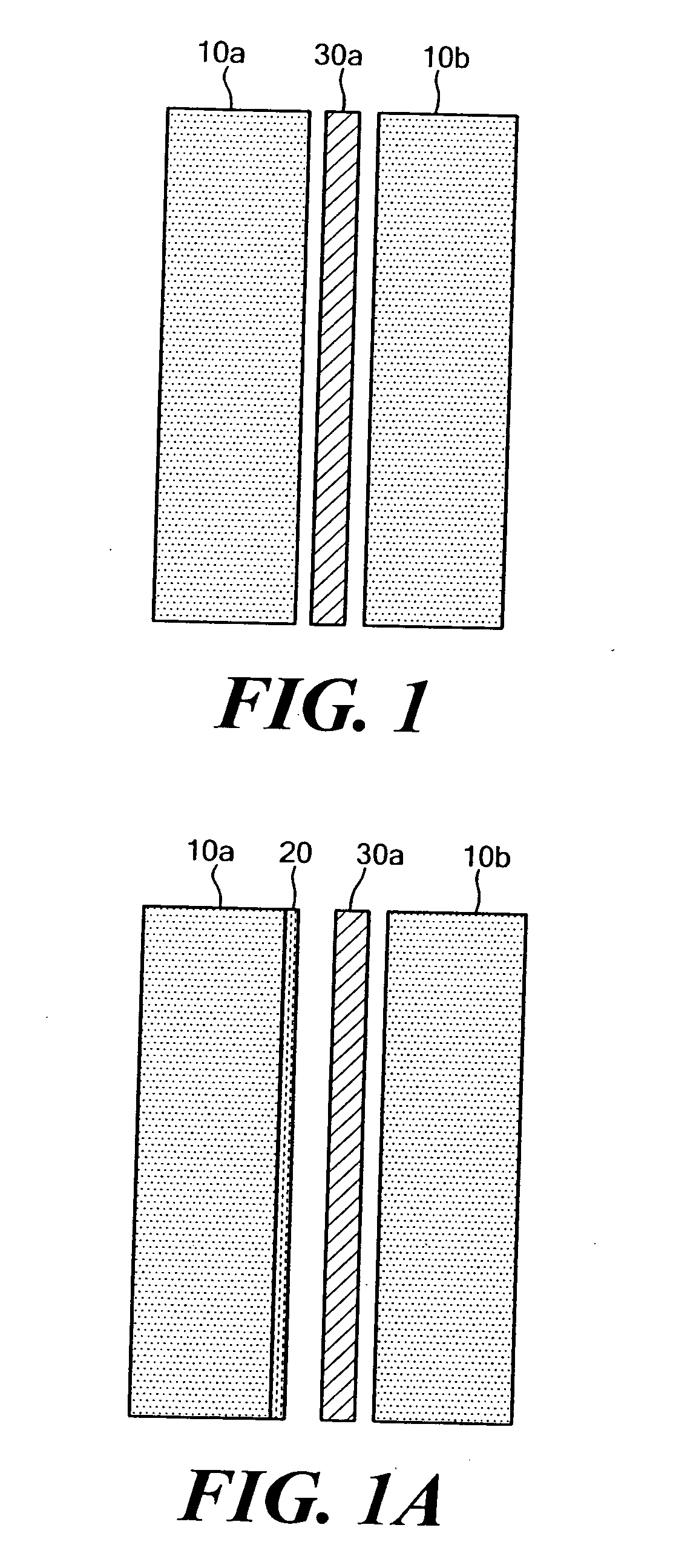

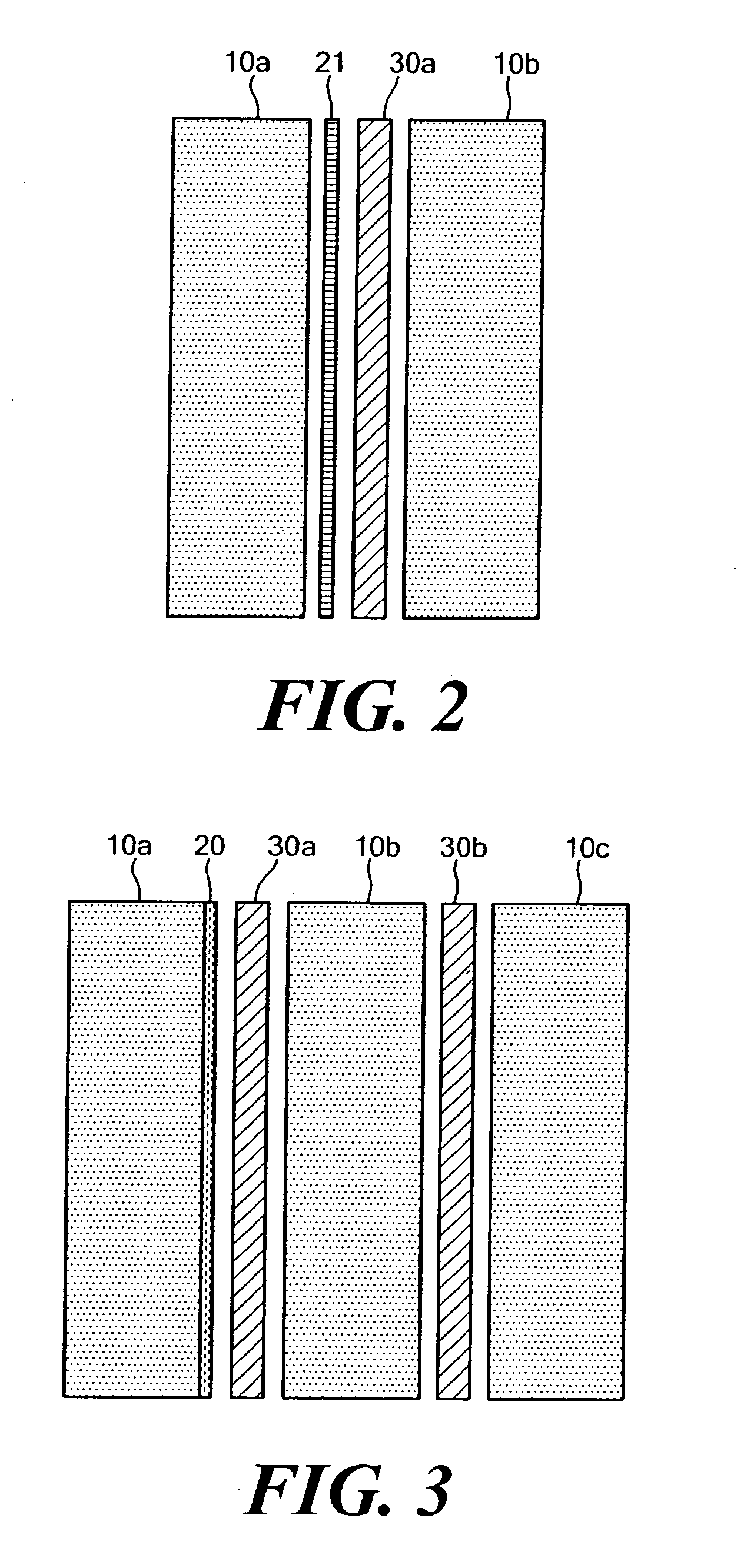

Photochromic film material

InactiveUS20050136260A1Improve the immunityMinimizing penetrationPhotosensitive materialsSynthetic resin layered productsHeat stabilityNear infrared radiation

The invention is directed to a photochromic material that filters, from solar radiation, near infrared radiation and sufficient portions of ultraviolet radiation while transmitting actinic radiation in the wavelength range of about 341±5 nm. The light-transmitting photochromic material provides light and heat stability to achieve a longer useful life. This photochromic material is preferably incorporated in a multilayered structure with constituents provided on or contained within one or more layers to enhance the resistance to light fatigue.

Owner:LINTEC CORP

Package for medical device

InactiveUS20020197478A1High strengthImprove moisture resistanceDiagnosticsNon-optical adjunctsEngineeringMedical device

This invention provides a medical device container comprising thermoplastic materials wherein said container is transmissive over substantially all of the surface area of said container to greater than 30% of the radiation in the range of 240 to 280 nm which impinges upon said container, and wherein said container is impervious to microorganisms. The preferred medical device container houses a contact lens.

Owner:MUGGLI OLIVIER Y +1

Indicating plate for timepiece and production thereof

InactiveUS6538959B1Avoid viewingSufficient transmissionVisual indicationElectric indicationSolar cellElectroplating

An indicating plate for a timepiece is provided which is so structured as to prevent viewing of the solar cell and other items arranged thereunder through the indicating plate, which permits the same design expression as realized by the conventional metallic indicating plate and extensively increases a design variation inclusive of a ton (delicate hue) and pattern with superior-quality appearance and which has an excellent appearance quality to thereby ensure and enhance commercial value. The indicating plate for the timepiece is a timepiece indicating plate arranged on the front surface side of a solar cell housed in a timepiece. The timepiece indicating plate comprises a resin substrate through which light can be transmitted and metallic thin film layer coating formed on at least one side of the resin substrate by dry plating. The timepiece indicating plate not only is capable of preventing viewing of the solar cell from outside thereof through the timepiece indicating plate but also has a light transmission at least sufficient to cause the solar cell housed under the timepiece indicating plate to generate power.

Owner:YAMAMOTO CORPORATION +1

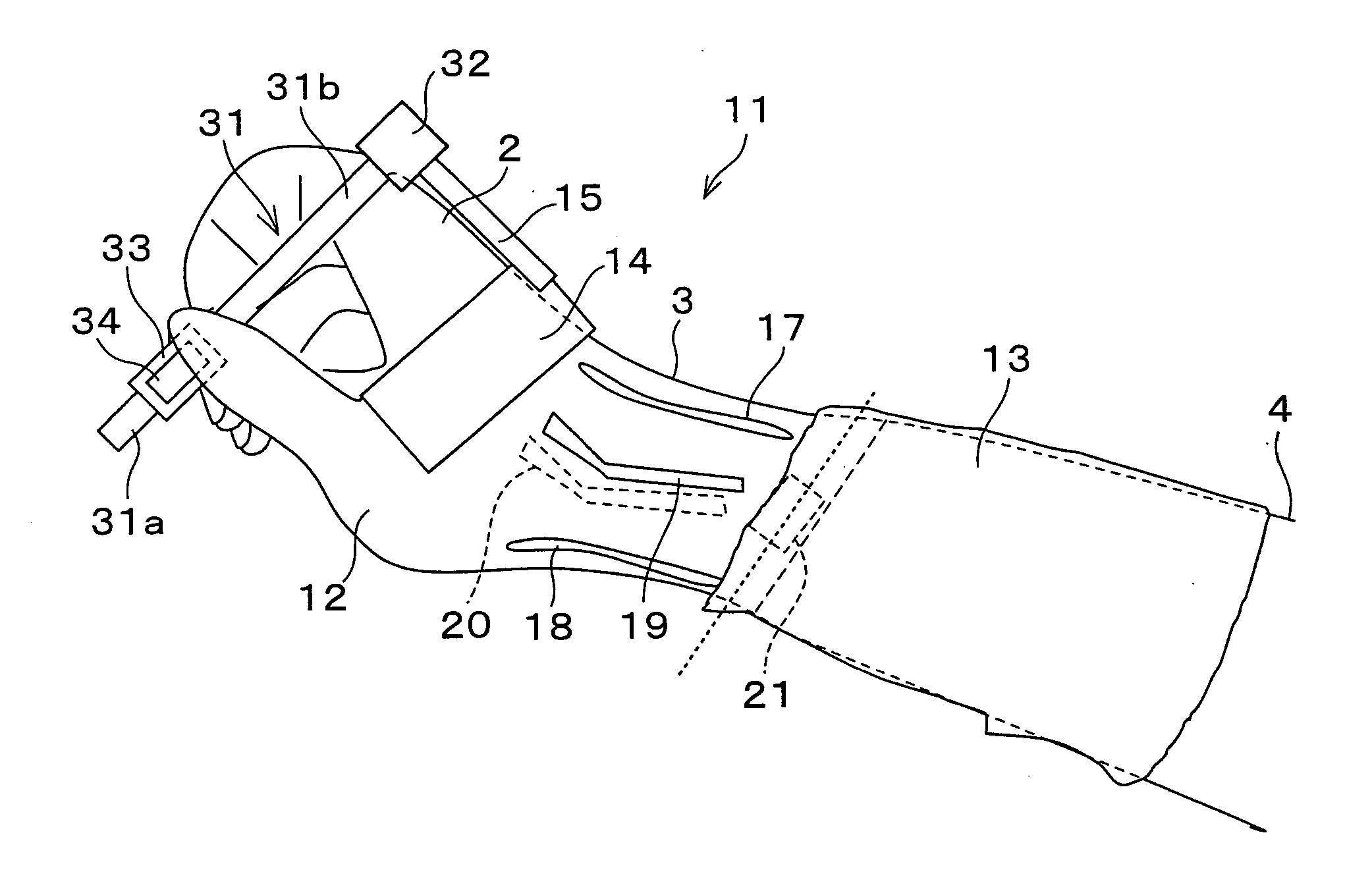

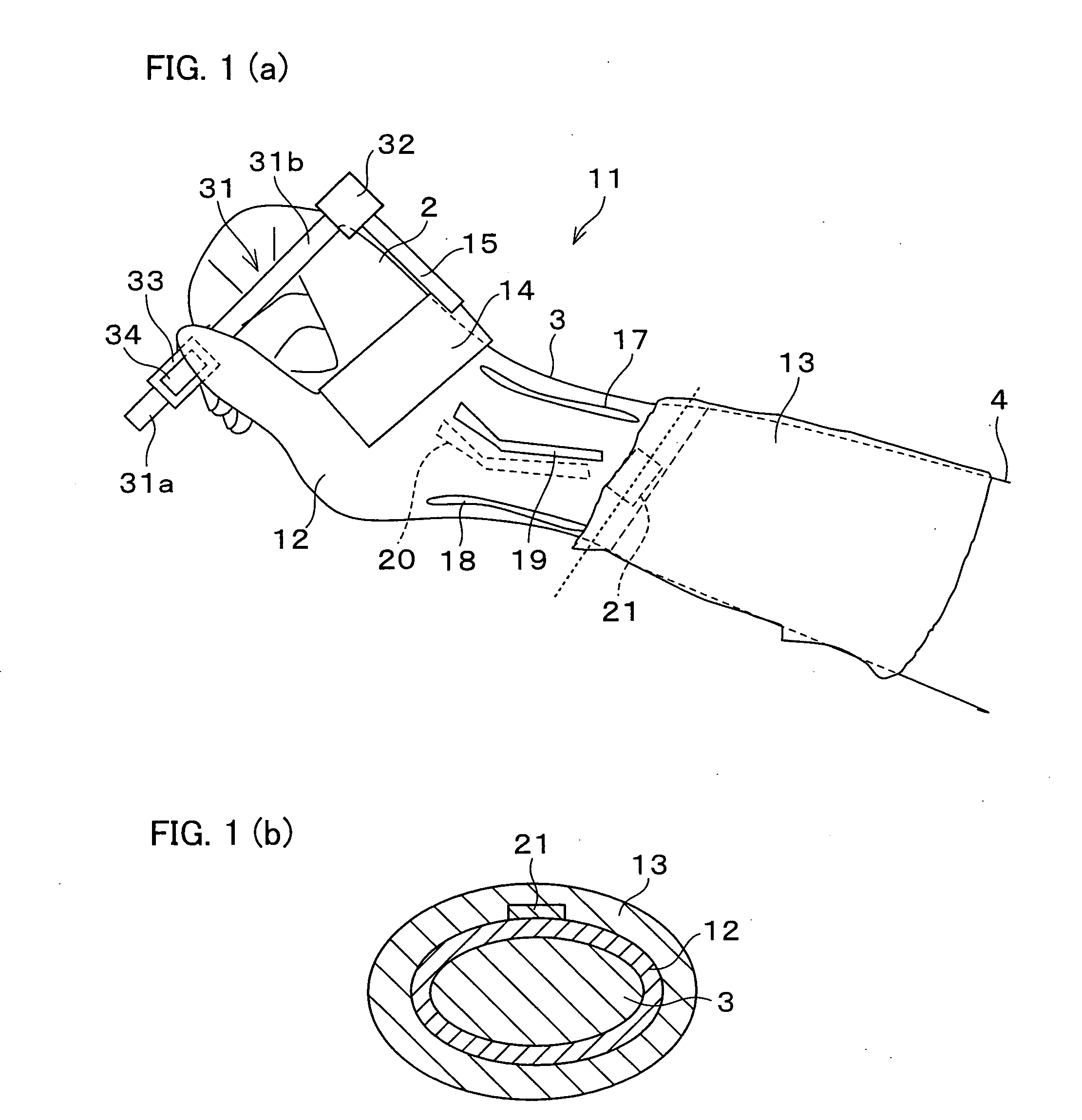

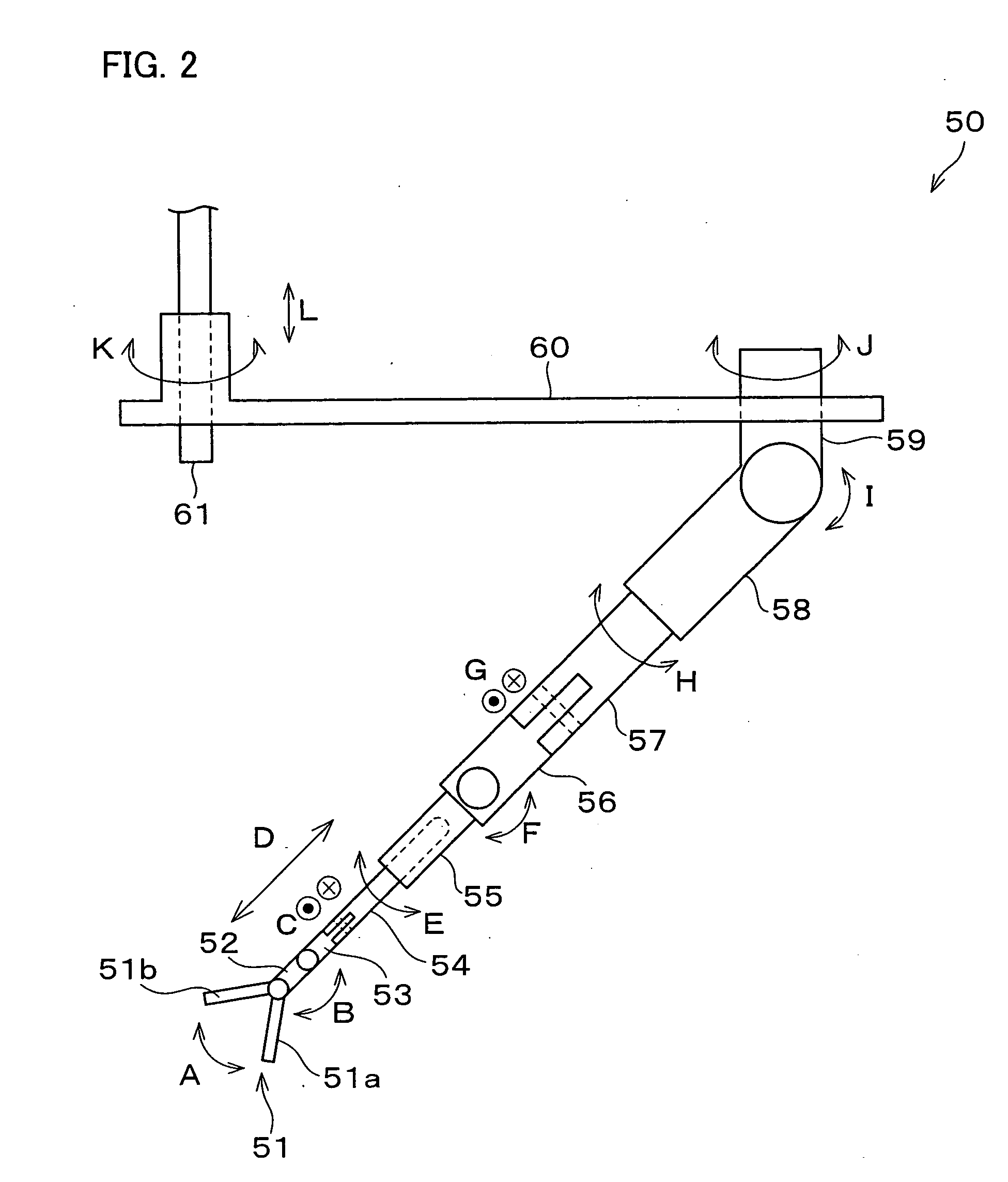

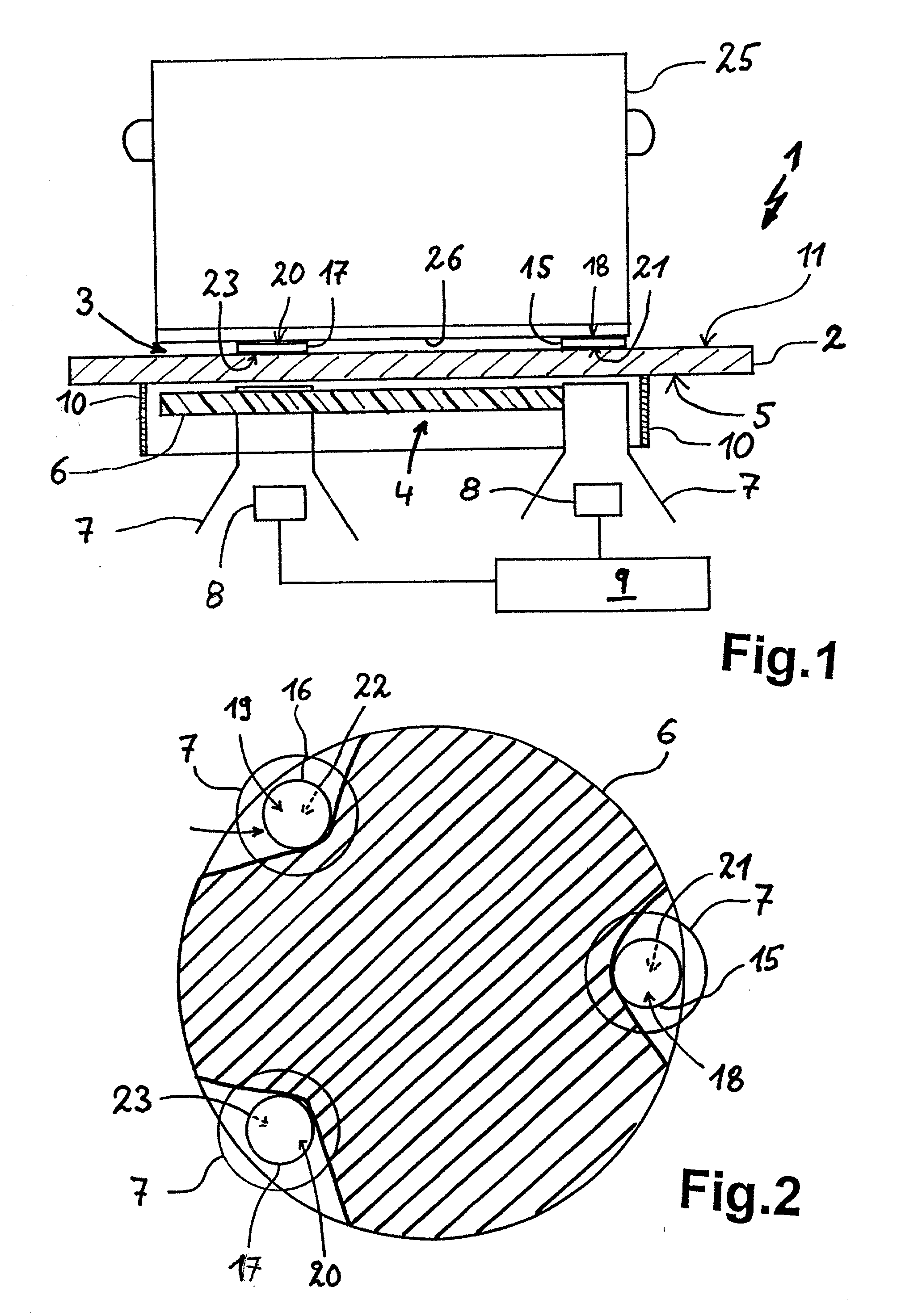

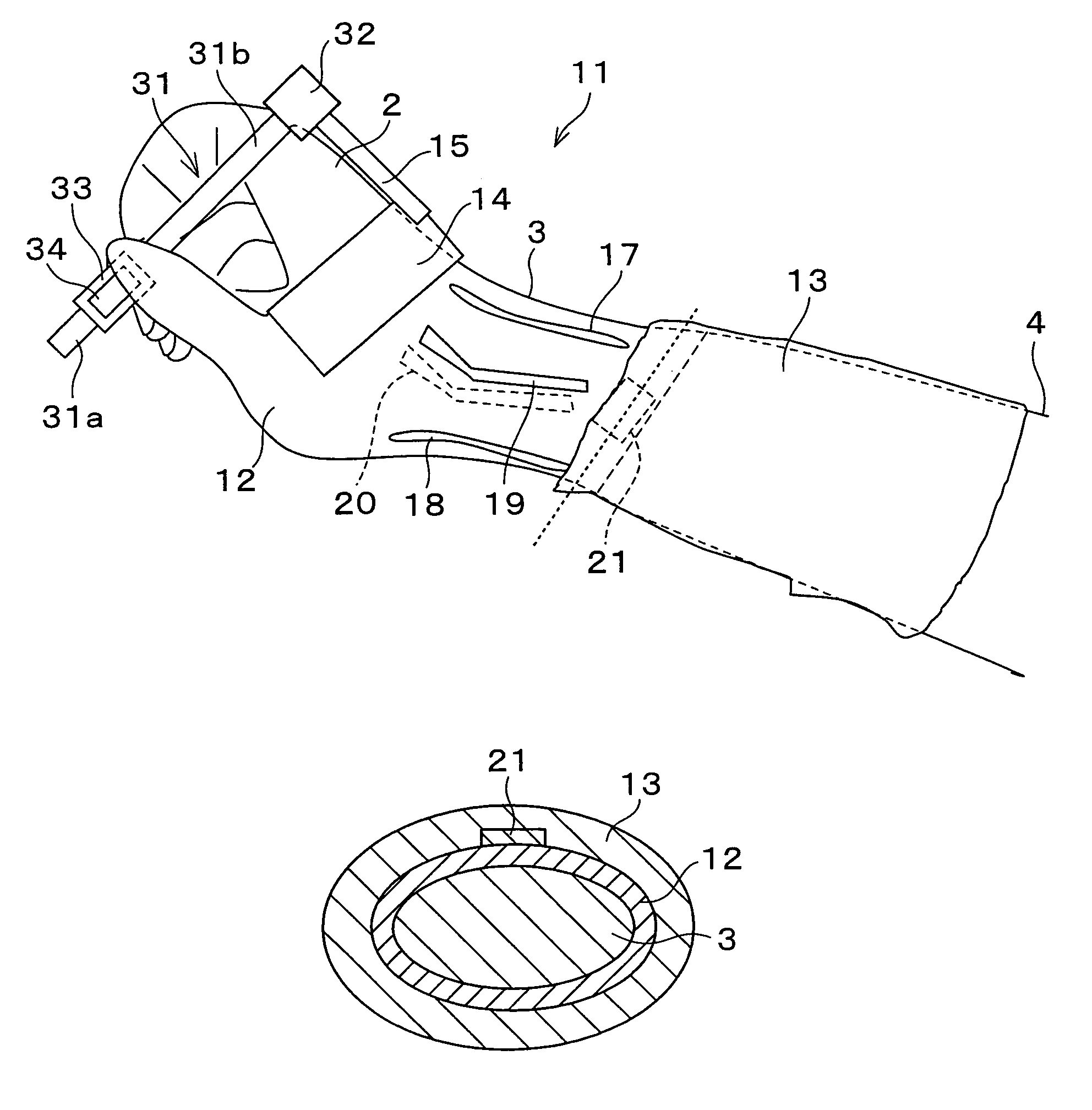

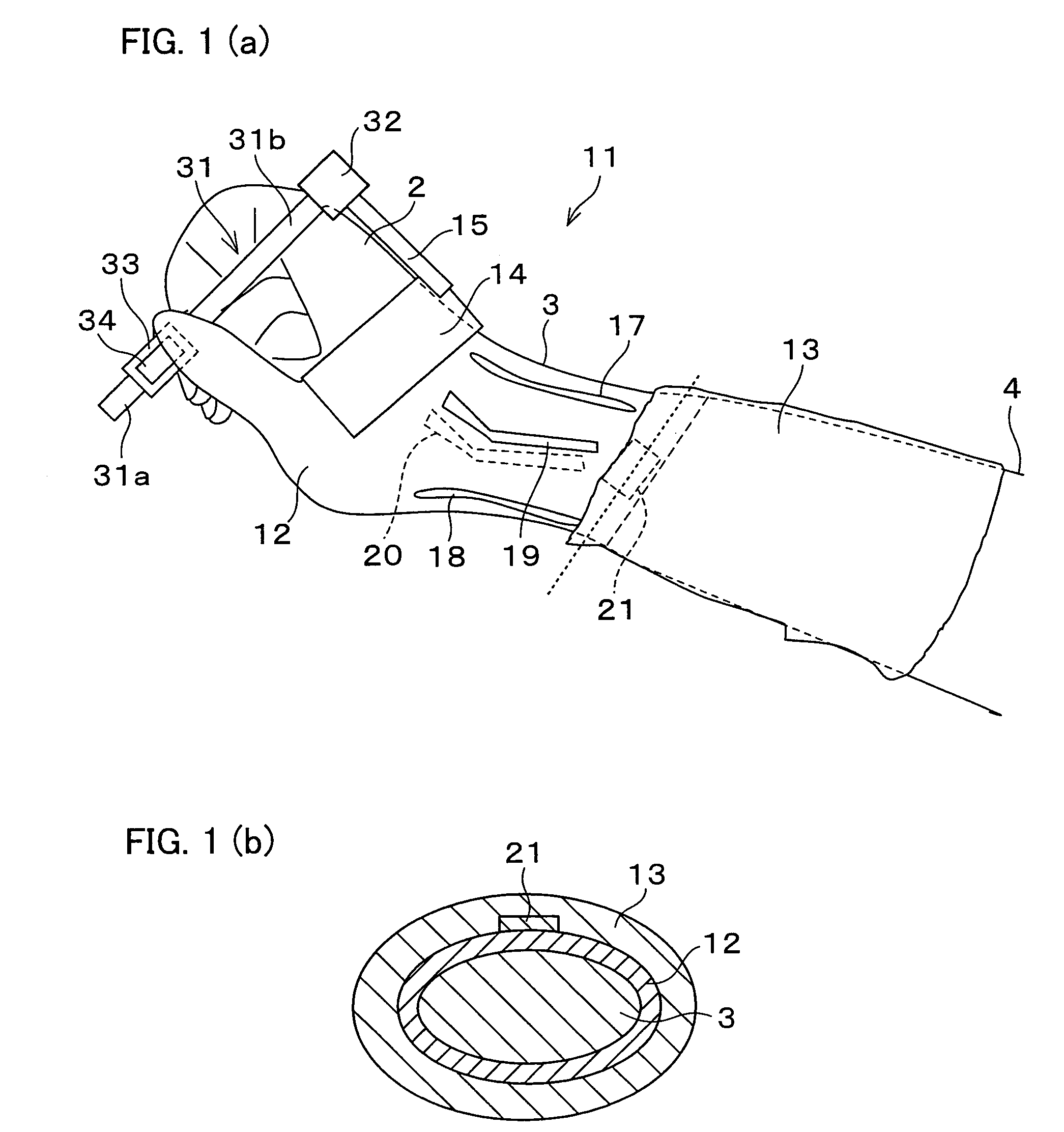

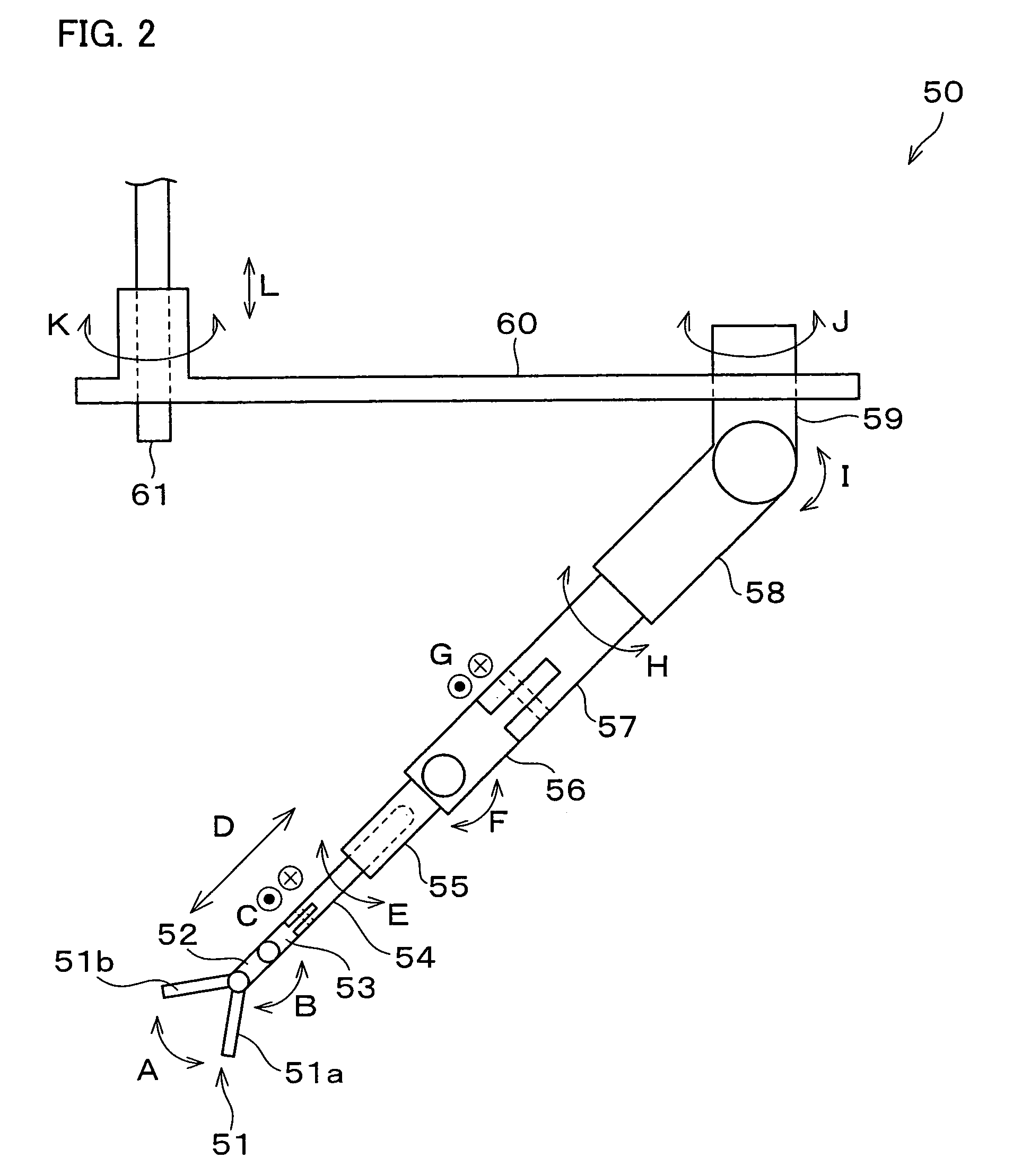

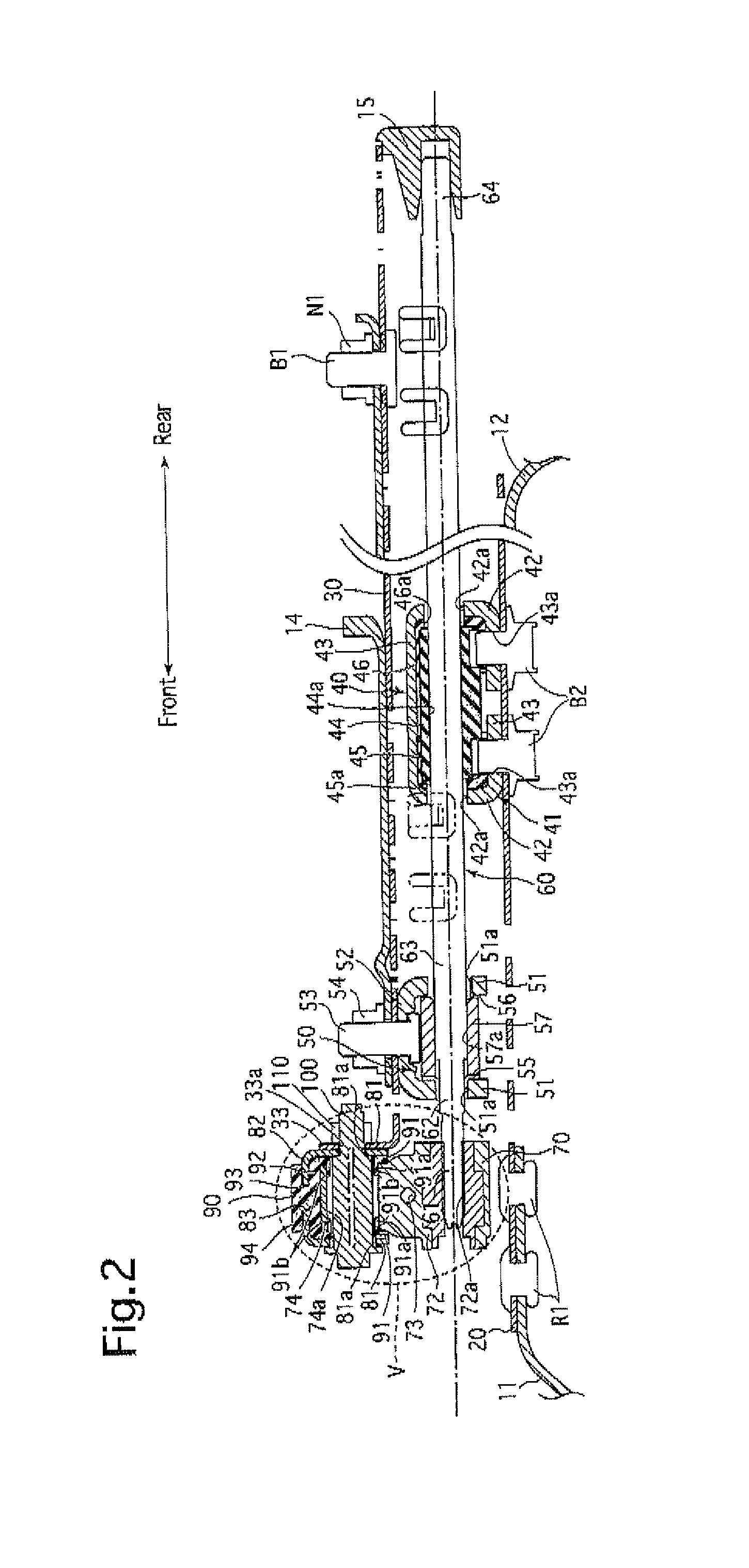

Surgical operation device

InactiveUS20060282063A1Easy to performMicrosurgery to be easilySuture equipmentsMechanical apparatusPotentiometerTorque sensor

In order to rotate and move an arm of a slave which supports a needle-holder, the rotation and movement of a pen-shaped operating section (31) caused by the fingers of the operator's hand are directly transmitted as the rotation and movement of the needle-holder, as sensors for detecting the rotation and movement of the operating section, an X-axis torque sensor, Y-axis torque sensor, Z-axis torque sensor, and a rotation detecting potentiometer (33) are installed thereon. As a result, the rotation and movement of the pen-shaped operating section (31) caused by the fingers of the operator's hand are transmitted as the rotation and movement of the needle-holder in optimum proportions through a computing section. Therefore, when the needle-holder is to be finely moved, a subtle motion of the fingers of the hand can be satisfactorily transmitted. Thereby, it is possible to provide a surgical operation device capable of doing minute surgical operations with ease.

Owner:JAPAN SCI & TECH CORP

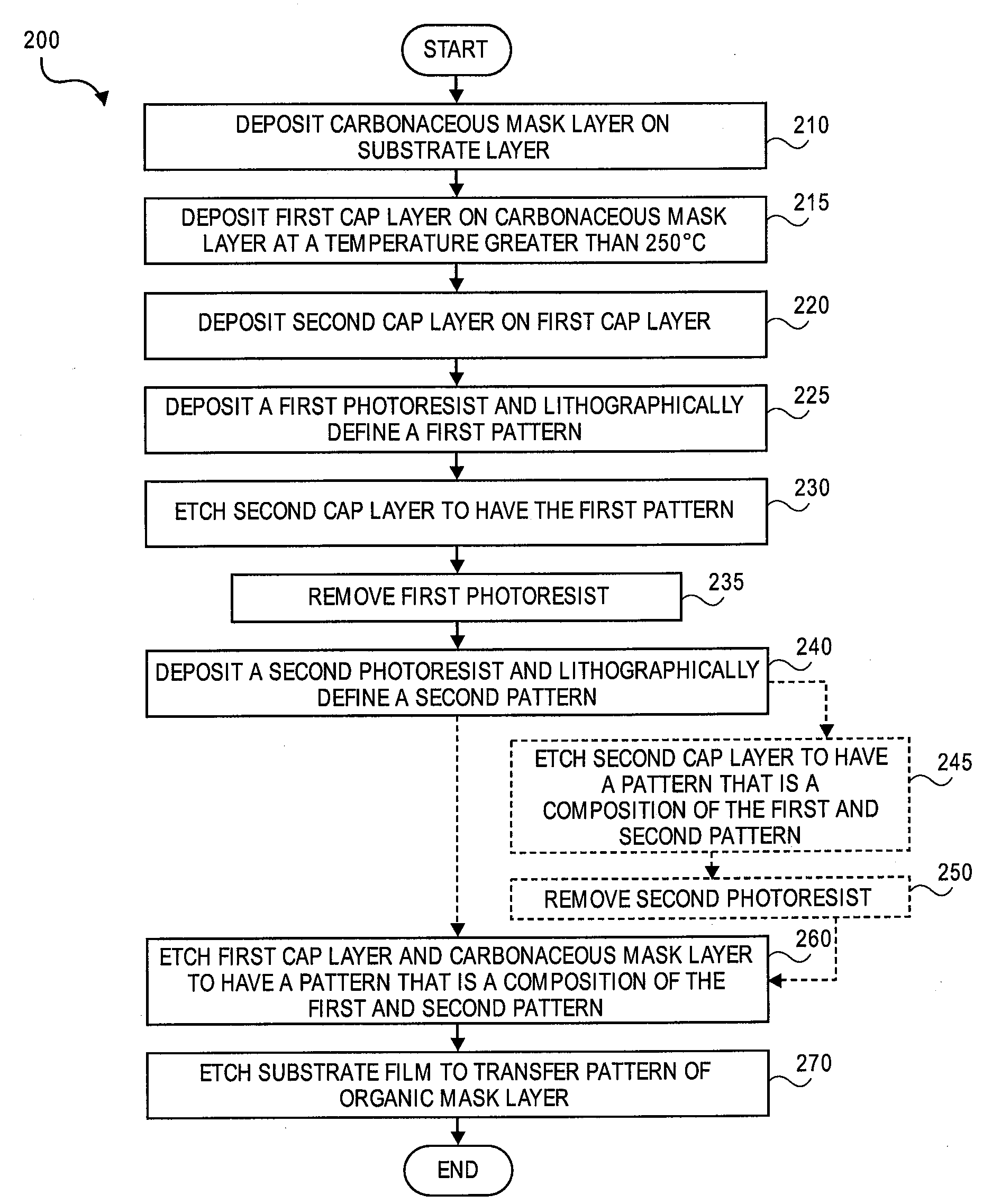

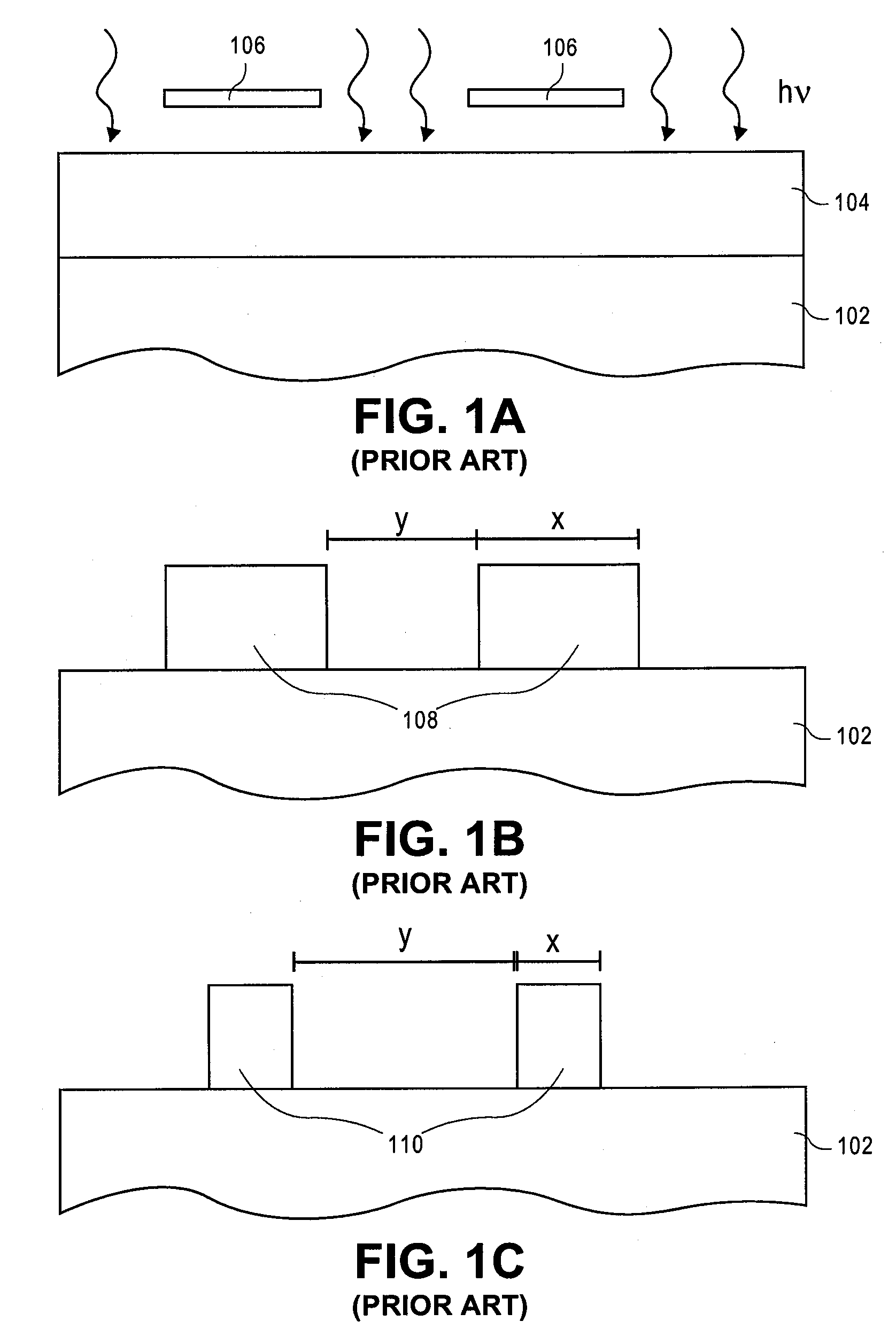

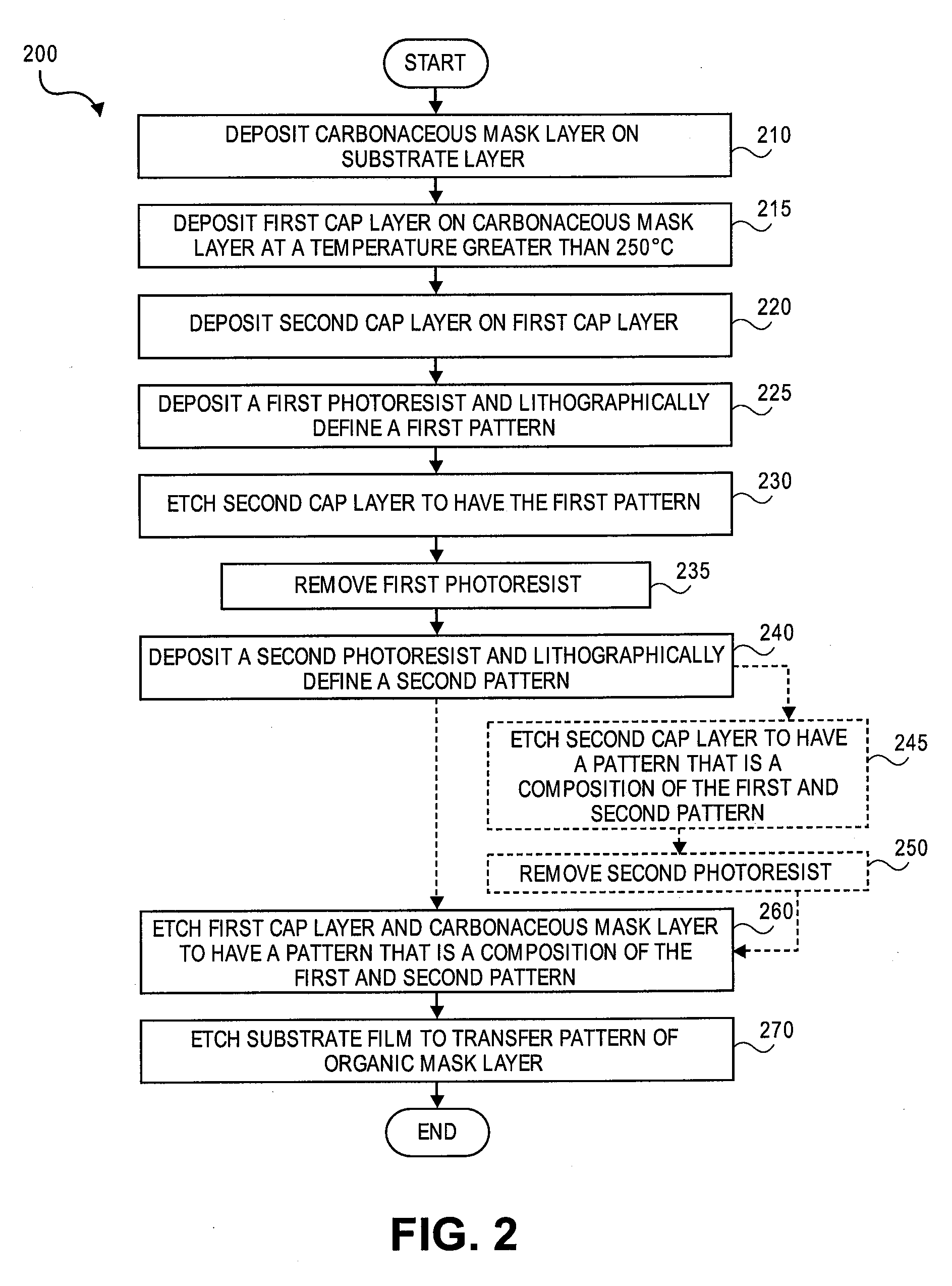

Double patterning with a double layer cap on carbonaceous hardmask

InactiveUS20080299494A1Increase flexibilityIncrease depositionPhotomechanical apparatusSemiconductor/solid-state device manufacturingMultiple layerMask layer

Methods to etch features in a substrate with a multi-layered double patterning mask. The multi-layered double patterning mask includes a carbonaceous mask layer, a first cap layer on the carbonaceous mask layer and a second cap layer on the first cap layer. After forming the multi-layered mask, a first lithographically defined pattern is etched into the second cap layer. A double pattern that is a composition of the first lithographically defined pattern etched in the second cap layer and a second lithographically defined pattern is then etched into the first cap layer and the carbonaceous mask layer. The double pattern formed in the carbonaceous mask layer is then transferred to a substrate layer and any portion of the multi-layered mask remaining is then removed.

Owner:APPLIED MATERIALS INC

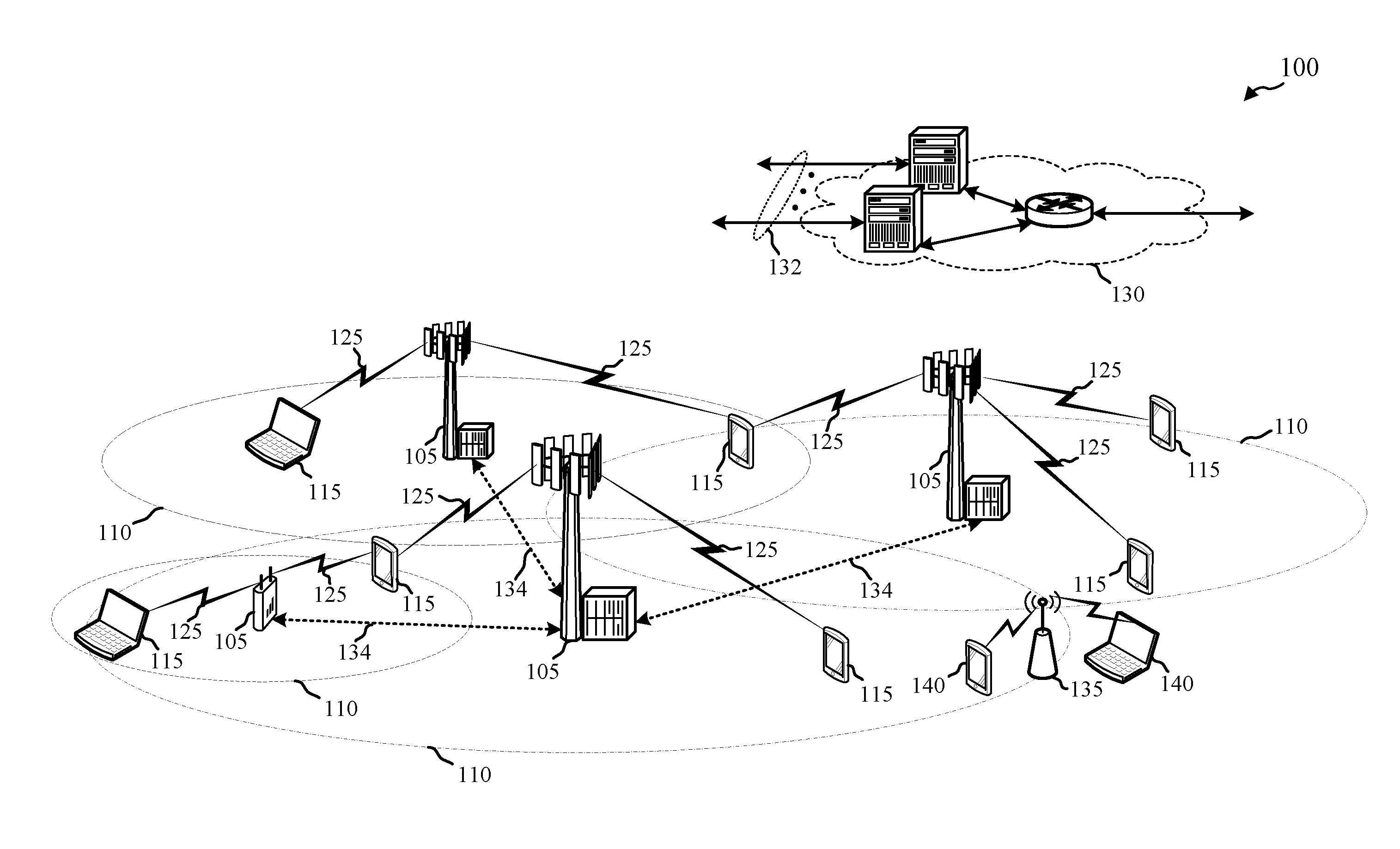

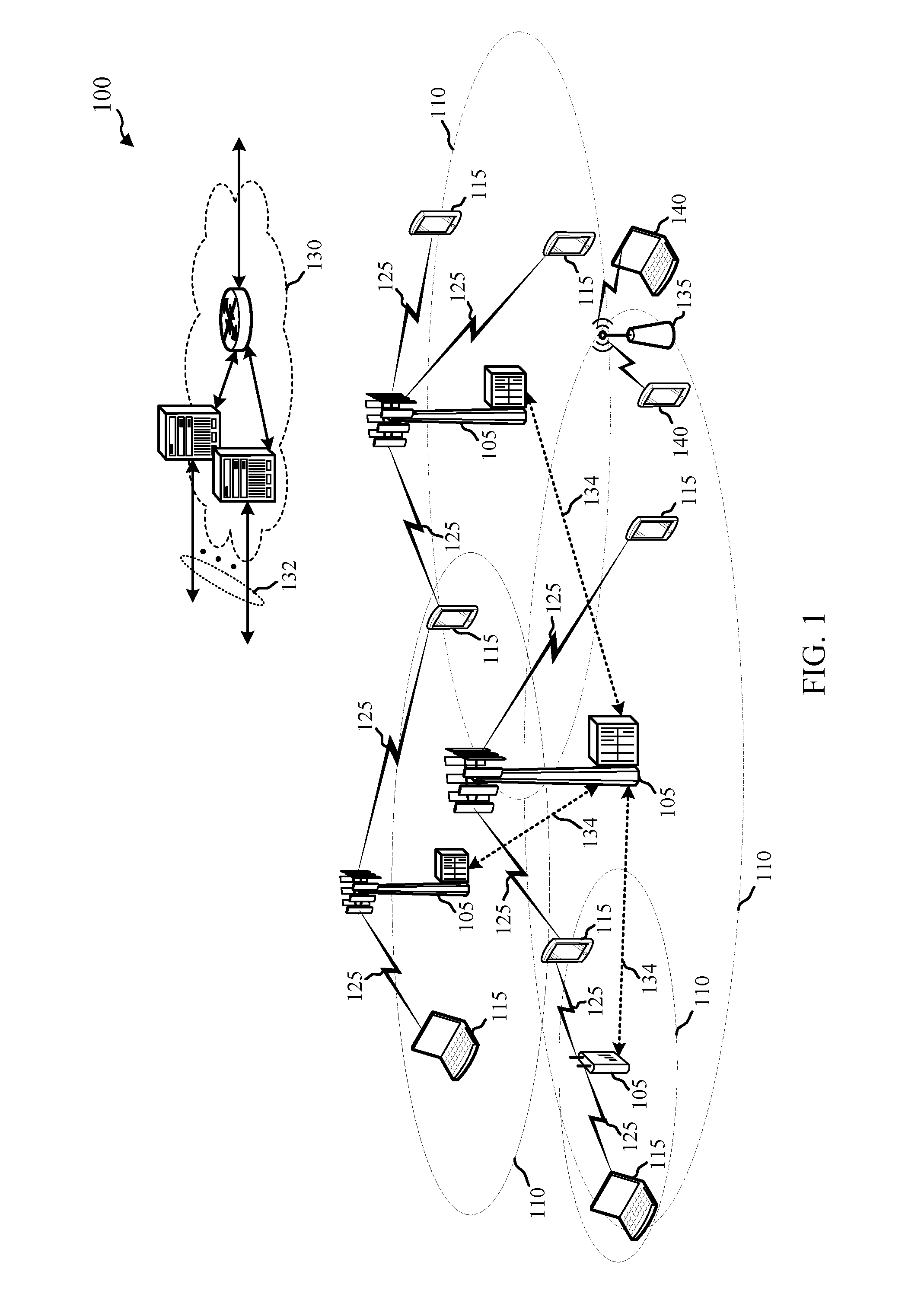

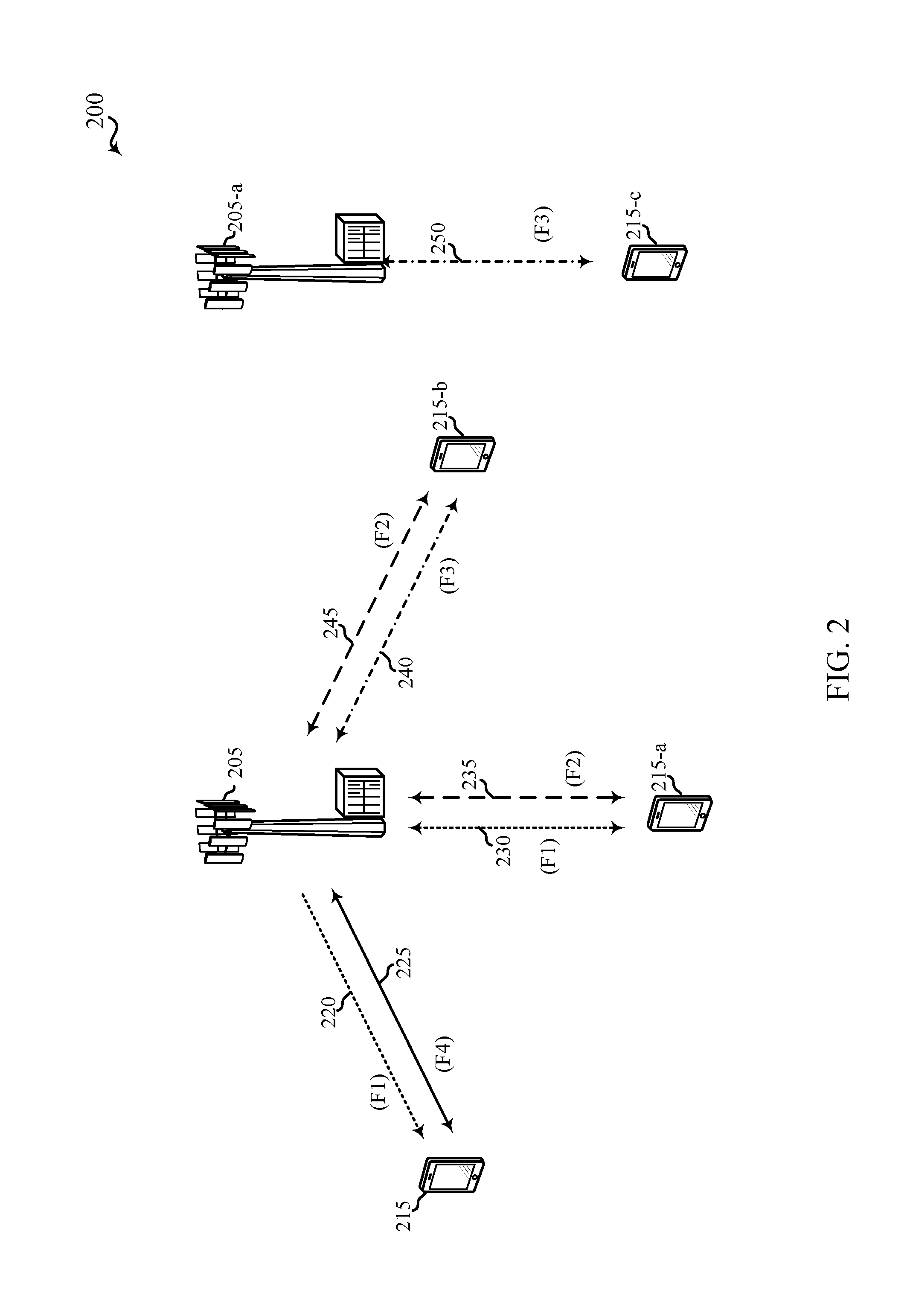

Techniques for reserving a channel of a radio frequency spectrum

ActiveUS20160174109A1Sufficient transmissionNetwork traffic/resource managementWireless commuication servicesRadio access technologyFrequency spectrum

Techniques are described for wireless communication. A first method includes contending for access to a first channel of a radio frequency spectrum, and transmitting, upon winning contention for access to the first channel, a first channel reservation indication. The contending may be performed by a first node operating according to a first radio access technology. The first channel reservation indication may be understood by a second node operating according to a second radio access technology.

Owner:QUALCOMM INC

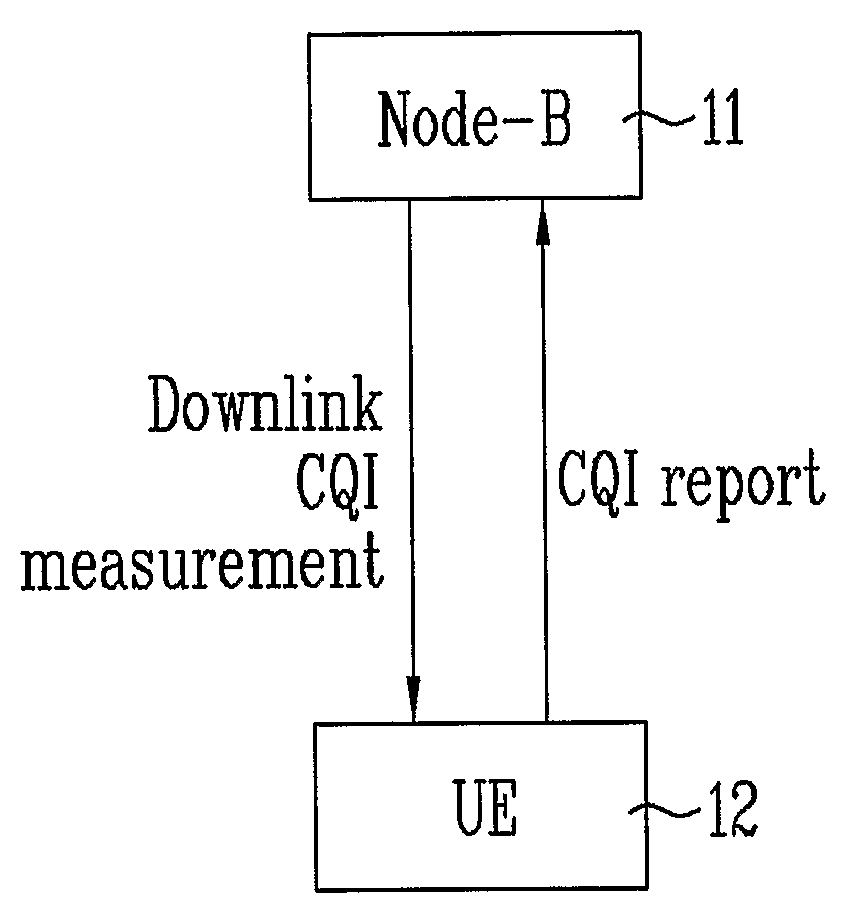

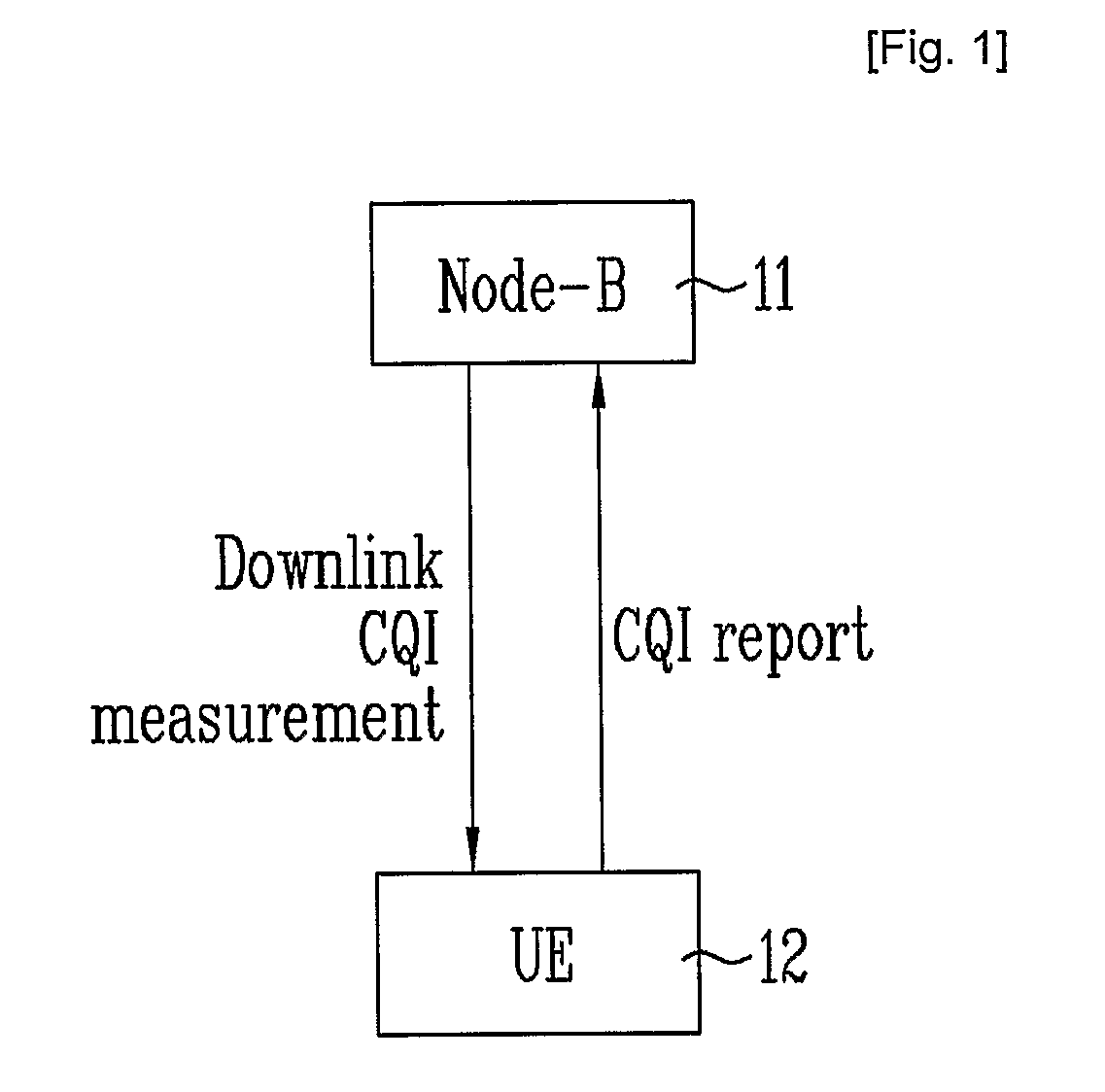

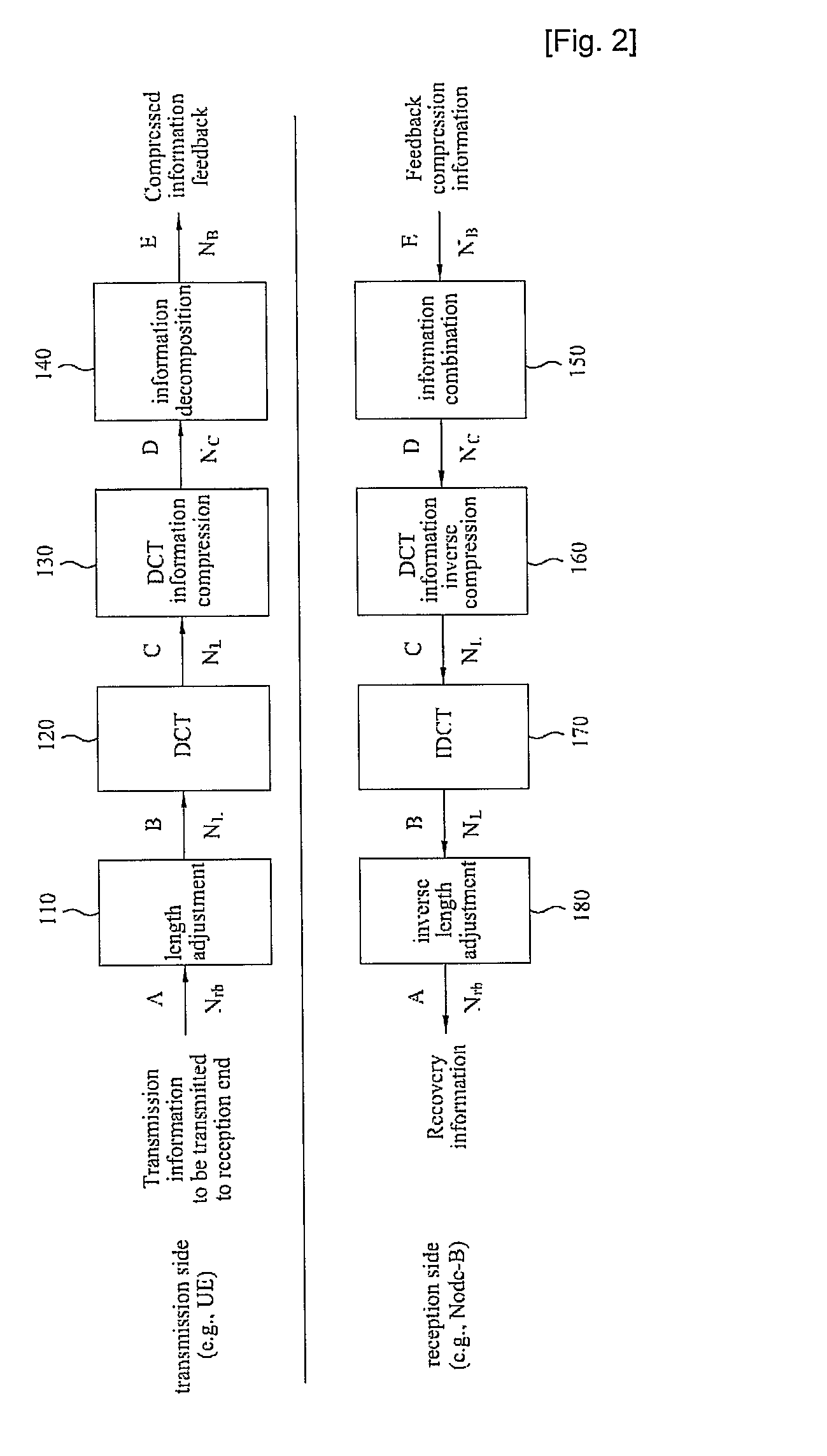

Method for transforming data, and method for transmitting and receiving data using the same

InactiveUS20090274220A1Minimizes amount of informationPerformance deteriorationError prevention/detection by using return channelDiversity/multi-antenna systemsCommunications systemCarrier signal

A method for transforming data to reduce an amount of data in a communication system equipped with several sub-carriers, and a data transmission method using the same are disclosed. The method for transmitting data using a Discrete Cosine Transform (DCT) in a communication system based on a plurality of sub-carriers includes: a) performing a Discrete Cosine Transform (DCT) on first data; b) selecting a predetermined number of data from among the DCT-processed first data, and performing data processing on the selected data; and c) transmitting the data-processed resultant data to a reception end. A method for reducing an amount of overhead of transmission data for use in the multi-antenna communication system is disclosed.

Owner:LG ELECTRONICS INC

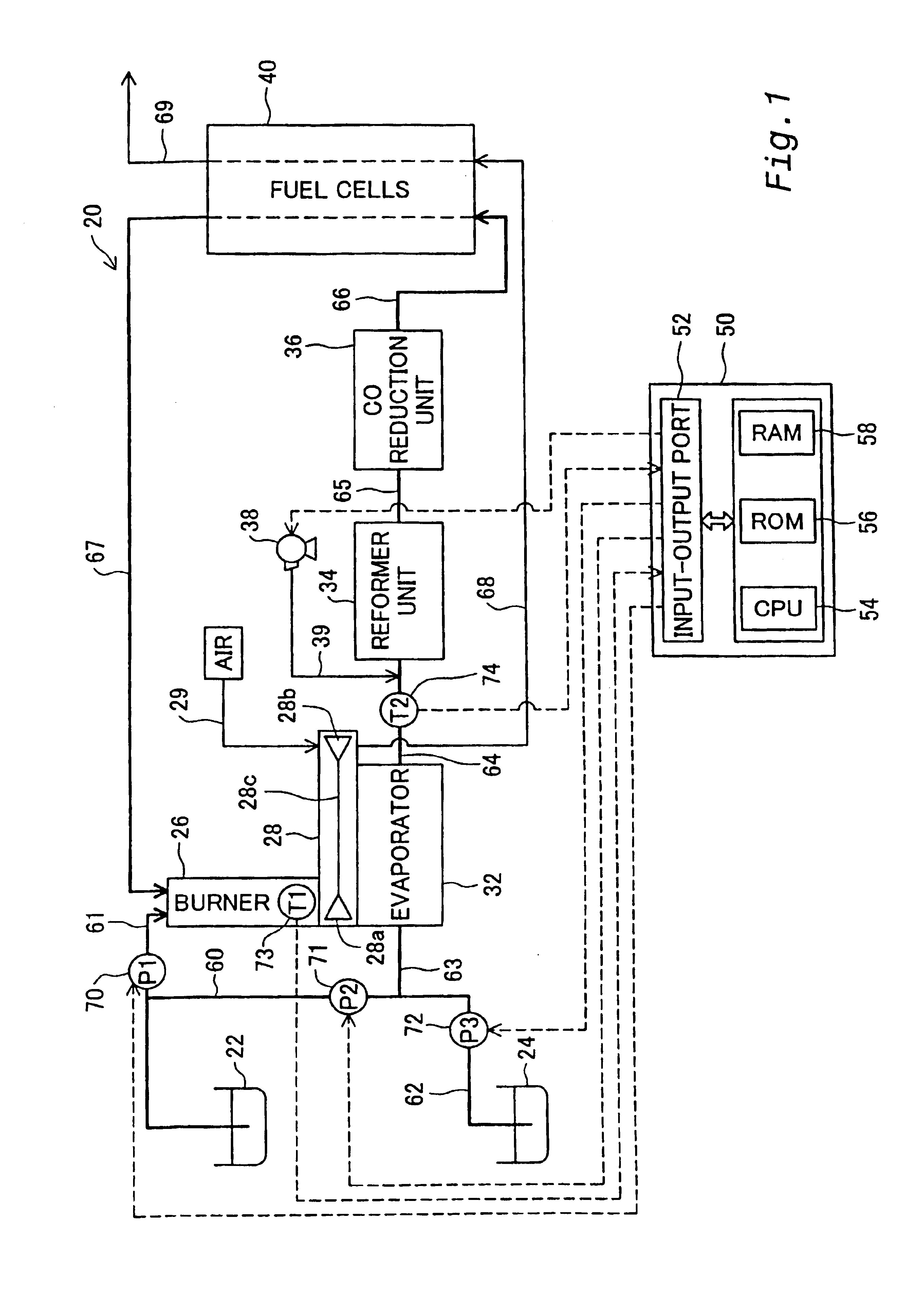

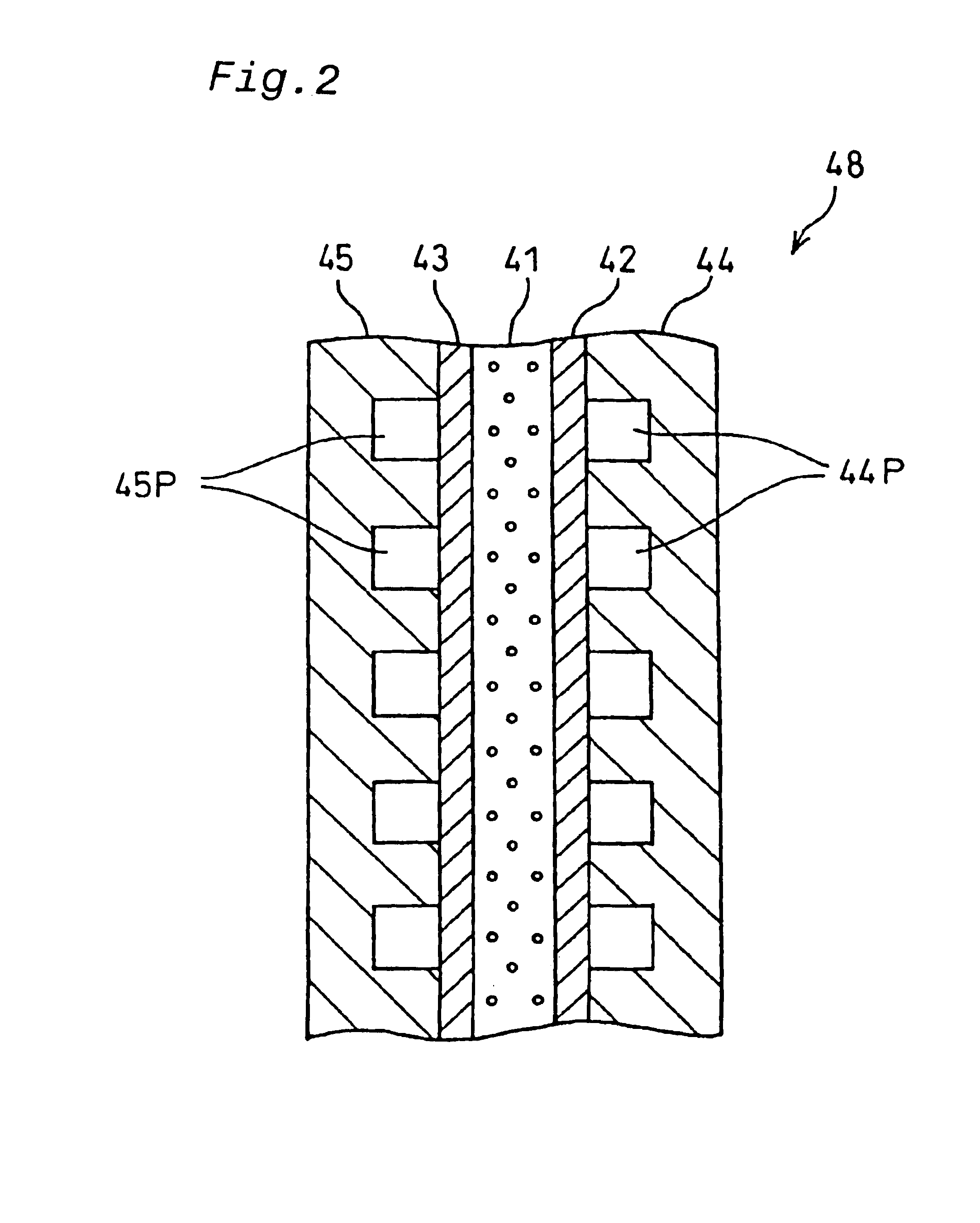

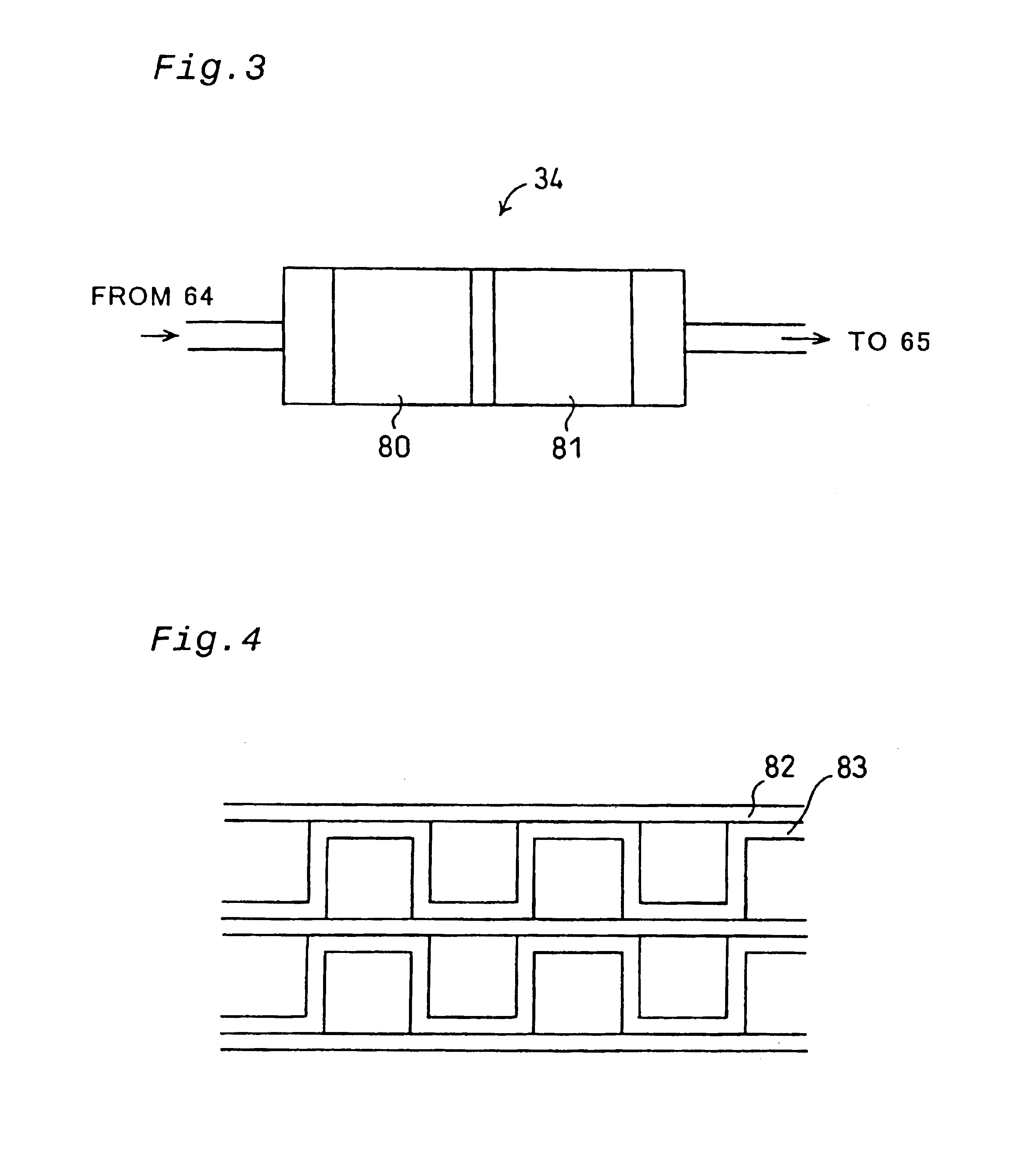

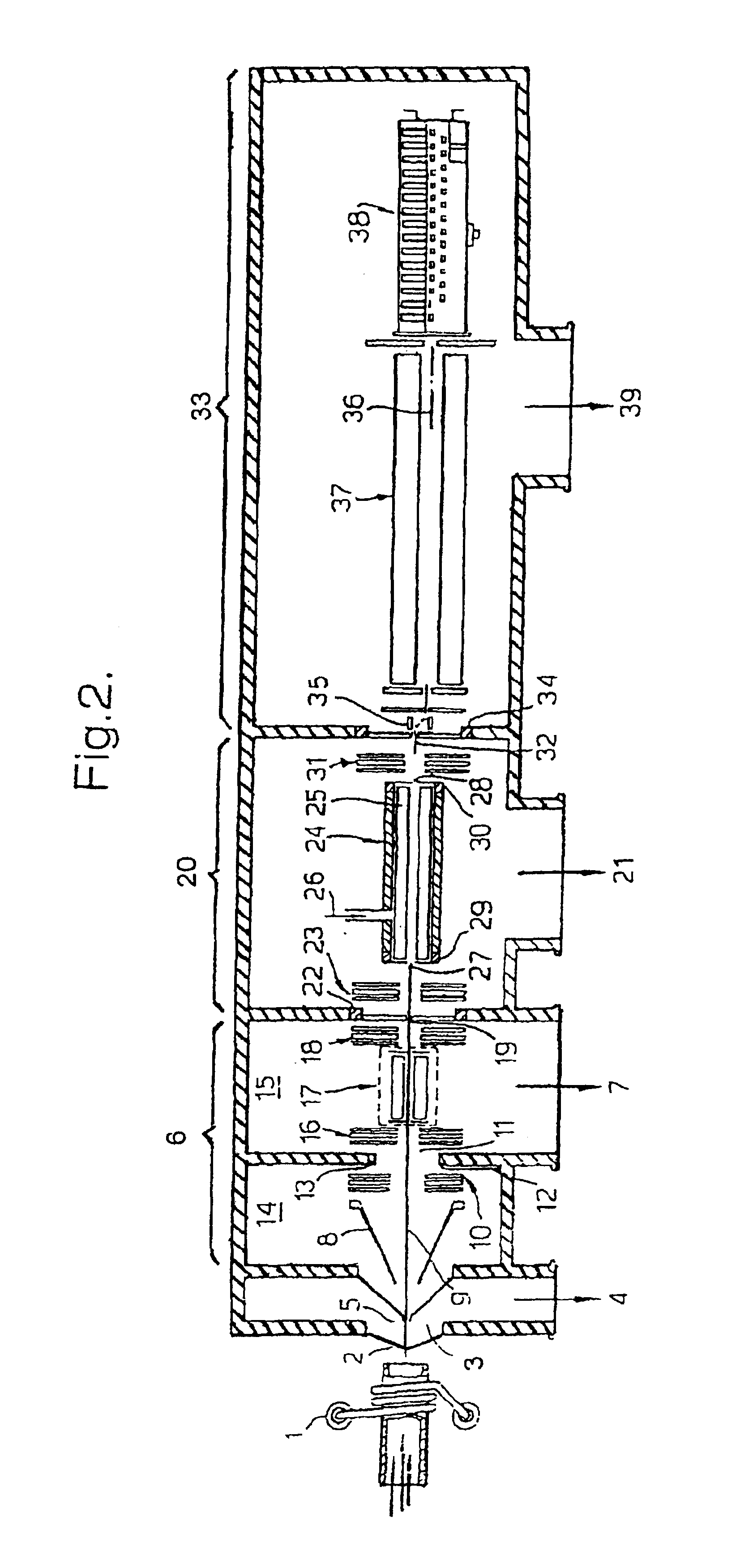

Fuel reformer device

InactiveUS6887286B1Simple structureImprove responseSolid electrolytesHydrogenSteam reformingHydrogen

The present invention is directed to a fuel reformer device that produces a hydrogen rich gas from a hydrocarbon and steam. The steam reforming reaction that produces the hydrogen rich gas from the hydrocarbon and steam is endothermic. A known technique supplies heat required for the steam reforming reaction by an exothermic oxidation reaction proceeding in parallel with the steam reforming reaction. This known technique may, however, cause an excessive temperature rise in an area of the vigorous oxidation reaction in the fuel reformer device.A reformer unit 34 including a Cu—Zn catalyst receives a supply of a crude fuel gas containing the air flown through a second fuel supply conduit 64. The crude fuel gas is subjected to the steam reforming reaction and the oxidation reaction proceeding inside the reformer unit 34. A resulting hydrogen rich gaseous fuel is discharged to a third fuel supply conduit 65. The reformer unit 34 includes an upper stream reaction unit 80 and a lower stream reaction unit 81. Both the reaction units 80 and 81 have honeycomb structures, wherein the total sectional area of the flow path in the upper stream reaction unit 80 is made smaller than the total sectional area of the flow path in the lower stream reaction unit 81. This arrangement causes the gas flowing through the reformer unit 34 to have the higher flow velocity on the upstream side than on the downstream side. The higher flow velocity on the upstream side extends the area of the vigorous oxidation reaction to the lower stream portion and enables the heat generated on the upstream side to be effectively transmitted to the lower stream portion. This arrangement thus effectively prevents an excessive temperature rise on the upstream side.

Owner:TOYOTA JIDOSHA KK

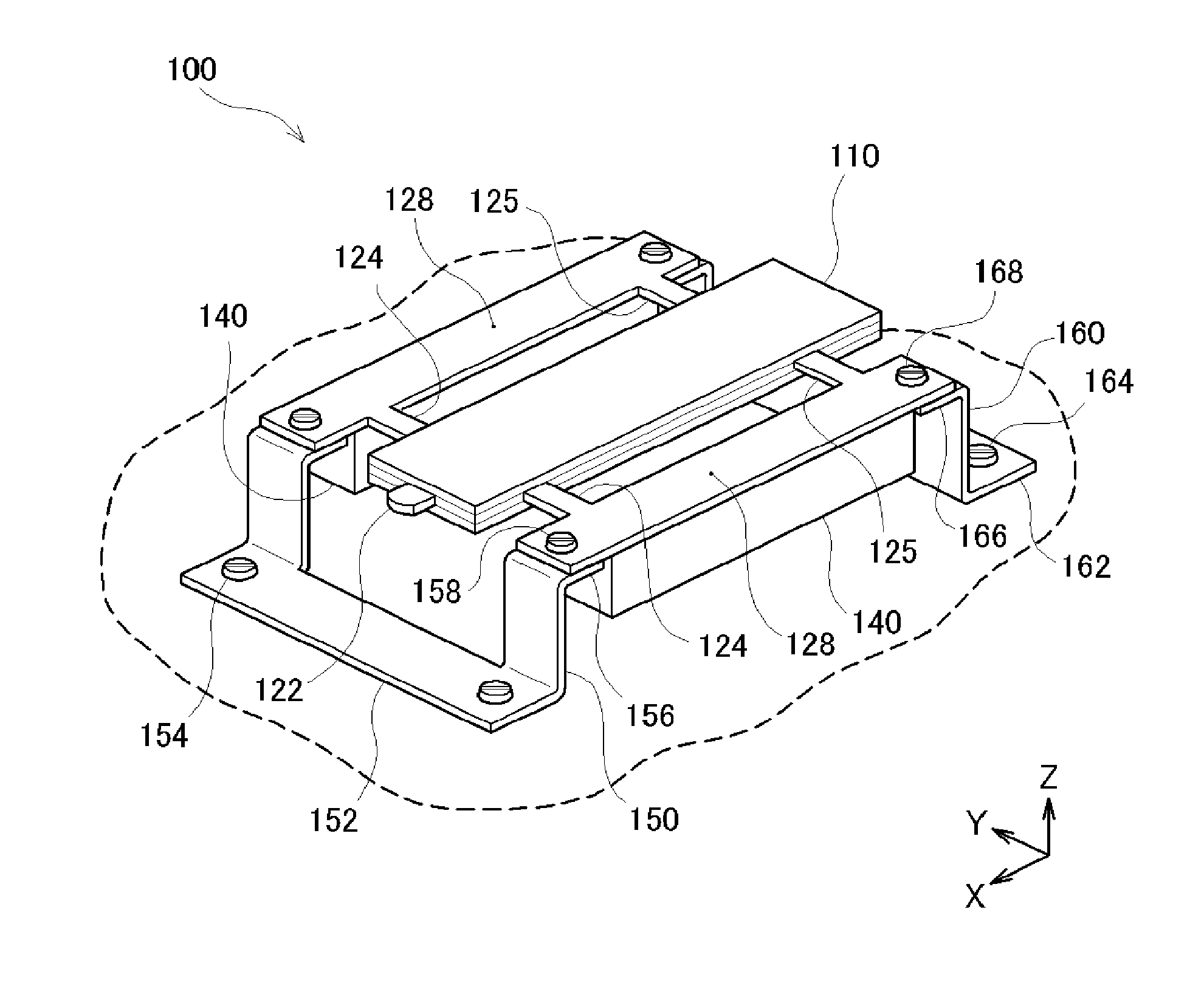

Piezoelectric motor, robot hand, robot, finger assist apparatus, electronic component conveying apparatus, electronic component inspecting apparatus, liquid feed pump, printing apparatus, electronic timepiece, and projecting apparatus

InactiveUS20150158184A1Improve support stiffnessAmount of deflectionMechanical apparatusPiezoelectric/electrostriction/magnetostriction machinesRobot handEngineering

A supporting portion disposed in parallel to a joint portion to which a vibrating body capable of generating a bending vibration is jointed and configured to support the vibrating body and the joint portion is provided, and the joint portion and the supporting portion are coupled with a plurality of coupling portions. The supporting portion has rigidity higher than that of the joint portion.

Owner:SEIKO EPSON CORP

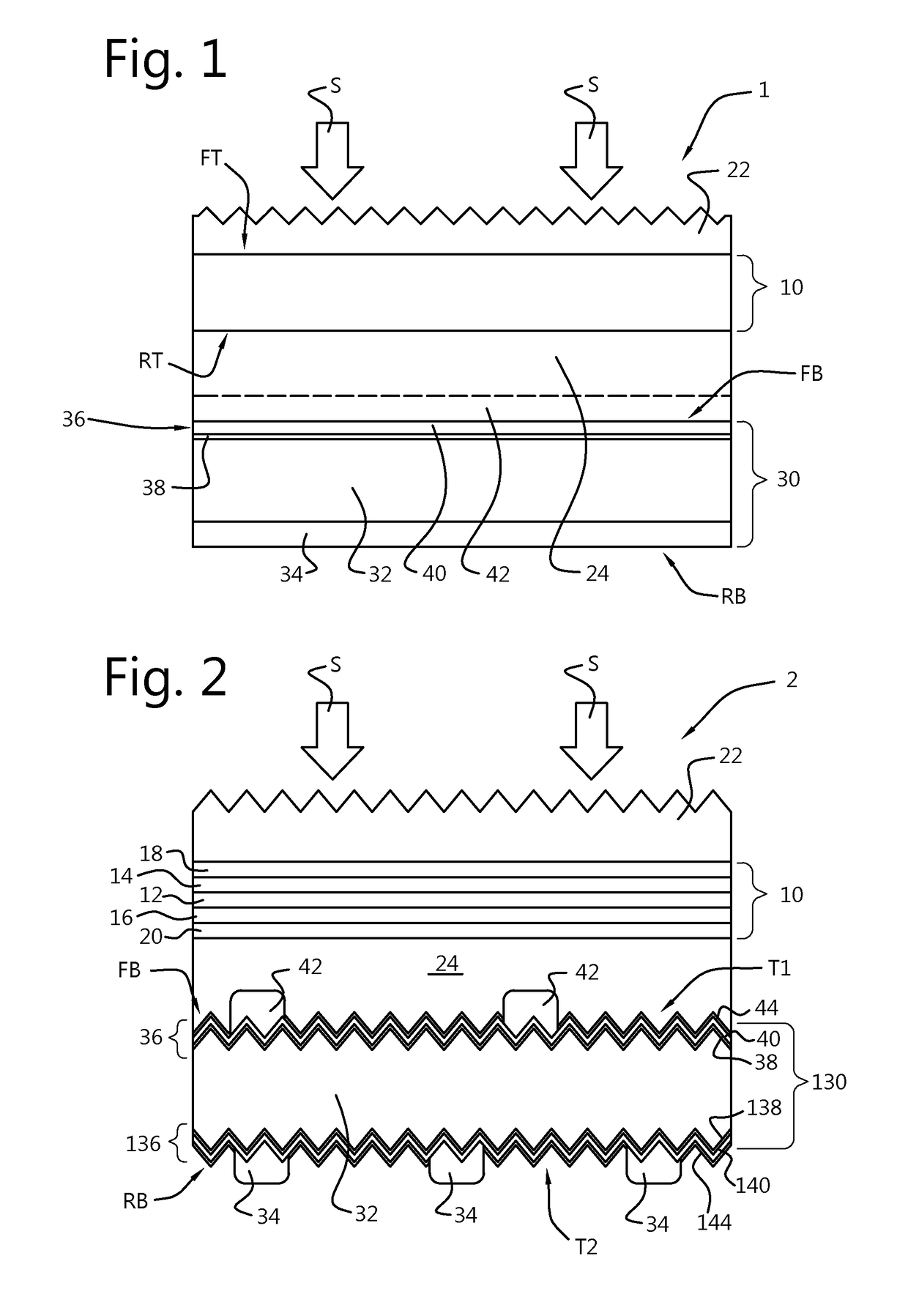

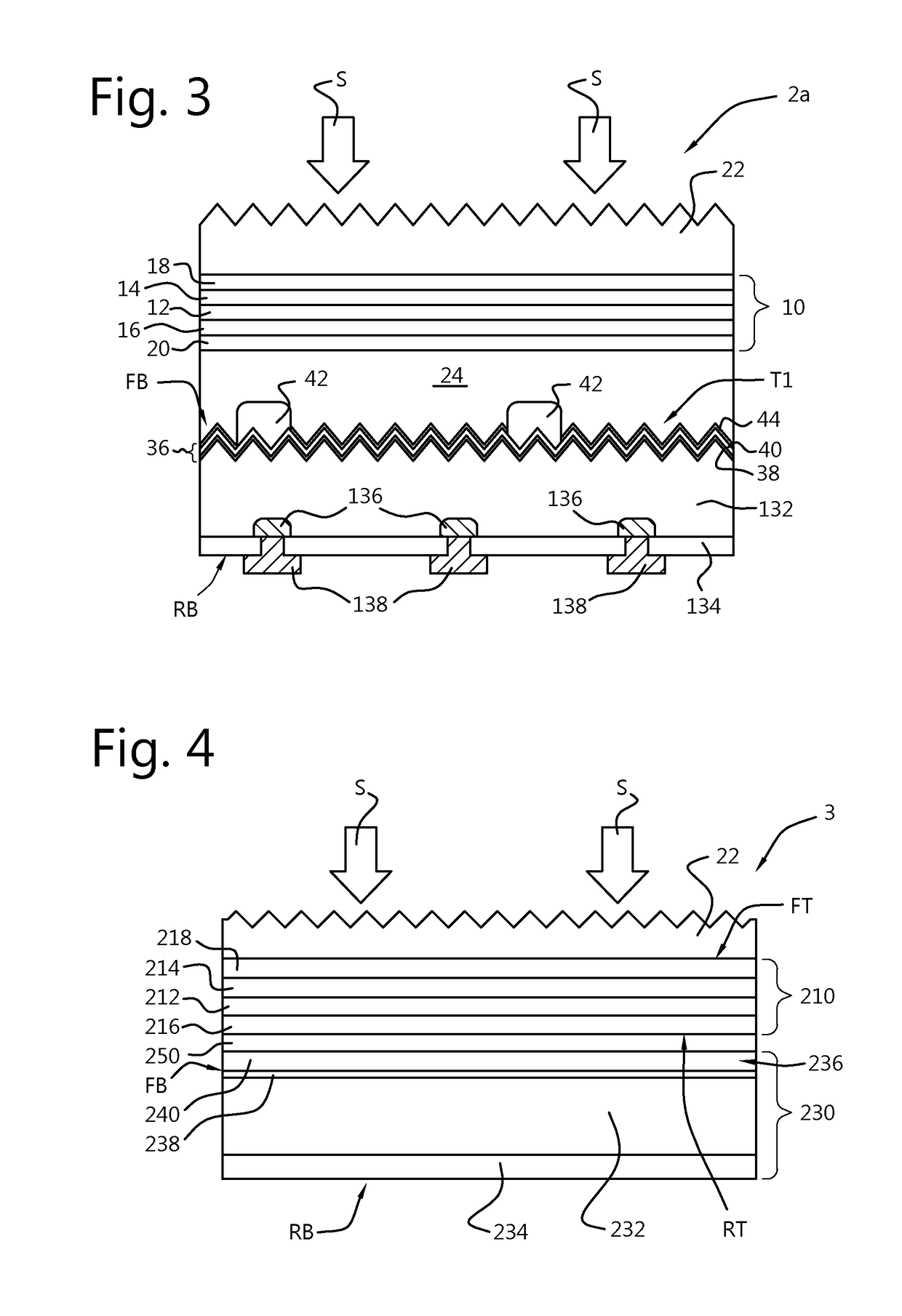

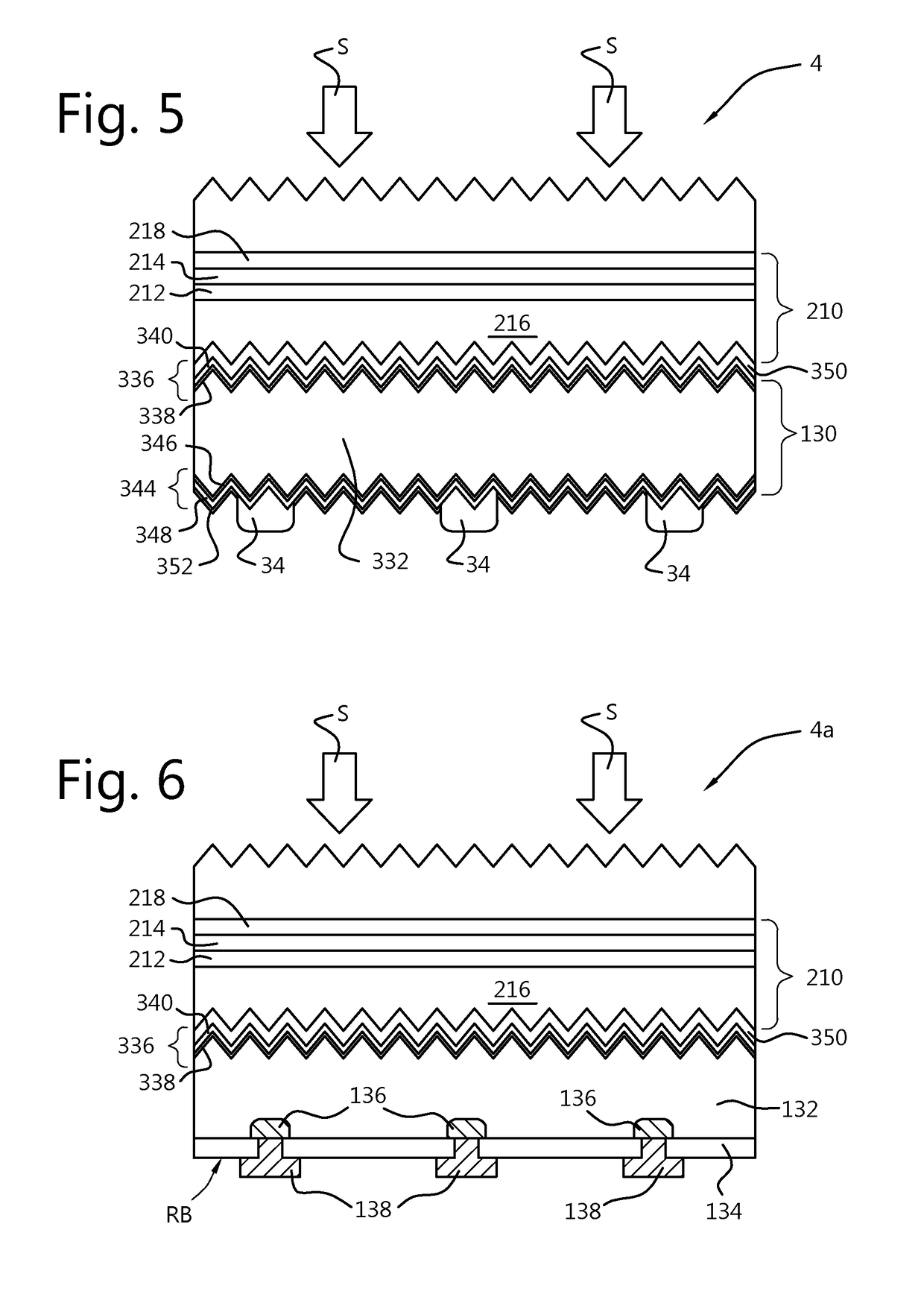

Hybrid tandem solar cell

ActiveUS20180374977A1Improve heat resistanceLow production costFinal product manufactureSolid-state devicesTandem solar cellEngineering

A tandem solar cell includes a top solar cell and a bottom solar cell. The top solar cell and the bottom solar cell each have a respective front surface and a rear surface, with the respective front surfaces being adapted for facing a radiation source during use. The top solar cell is arranged with its rear surface overlying the front surface of the bottom solar cell. The top solar cell includes a photovoltaic absorber layer with a bandgap greater than that of crystalline silicon. The bottom solar cell includes a crystalline silicon substrate. On at least a portion of the front surface of the bottom solar cell a passivating layer stack is disposed which includes a thin dielectric film and a secondary layer of either selective carrier extracting material or polysilicon. The thin dielectric film is arranged between the silicon substrate and the secondary layer.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Method and device for determining the temperature of a cooking vessel

InactiveUS20030206572A1Sufficient transmissionAccurate operationThermometer detailsRadiation pyrometryEngineeringGlass-ceramic

A description is given of a device and a method for determining the temperature of a cooking vessel placed on a hotplate of a heating appliance, e.g. on the glass ceramic plate of an inductive cooker, in the vicinity of a heating zone. In the vicinity of the heating zone is applied to the top of the hotplate at least one flat measuring element, e.g. formed by a colour coating and whose top surface comes into flat contact with the cooking vessel bottom on setting down the cooking vessel. As a result the temperature of the measuring element, by heat conduction, reliably matches the cooking vessel temperature, so that by determining the measuring element temperature it is possible to determine the cooking vessel temperature. The measuring element can serve as a reference measuring surface for infrared temperature measurement through the hotplate, the precision of the temperature measurement not being dependent on the emission capacity of the set down cooking vessel.

Owner:E G O ELEKTRO GERAETEBAU GMBH

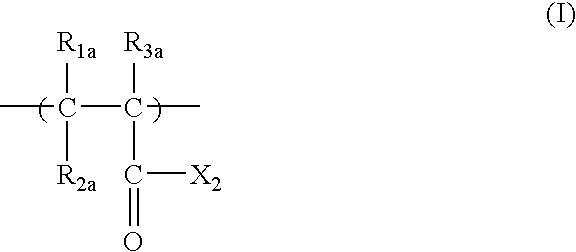

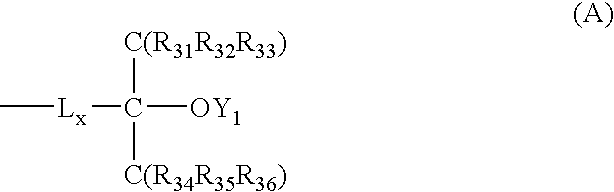

Positive resist composition and pattern formation method using the same

InactiveUS20050048402A1Sufficient transmissionIncrease contrastRadiation applicationsSemiconductor/solid-state device manufacturingActinic RaysRepeat unit

A positive resist composition comprising (A) a resin that is decomposed by the action of an acid to increase solubility in an alkali developing solution and includes a specific repeating unit and (B) a compound that generates an acid upon irradiation of an actinic ray or radiation, and a pattern formation method using the positive resist composition.

Owner:FUJIFILM HLDG CORP +1

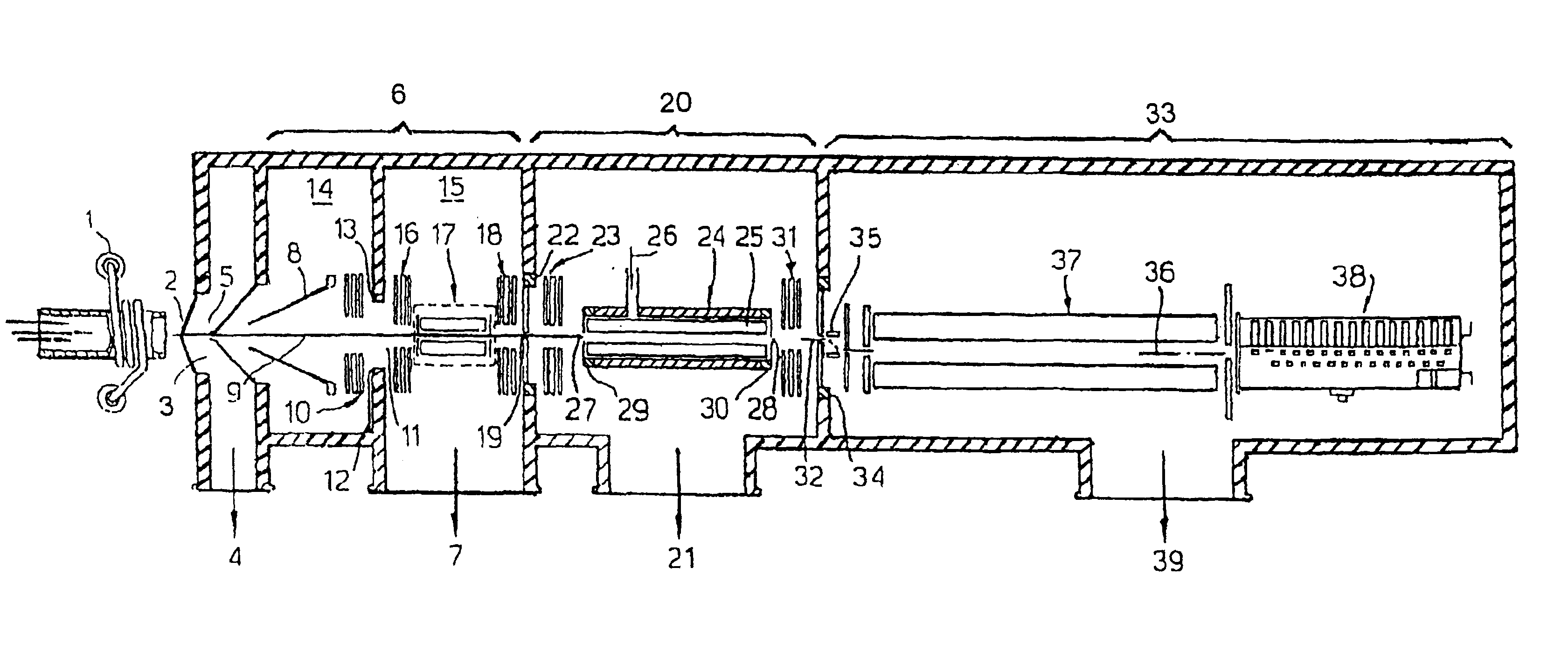

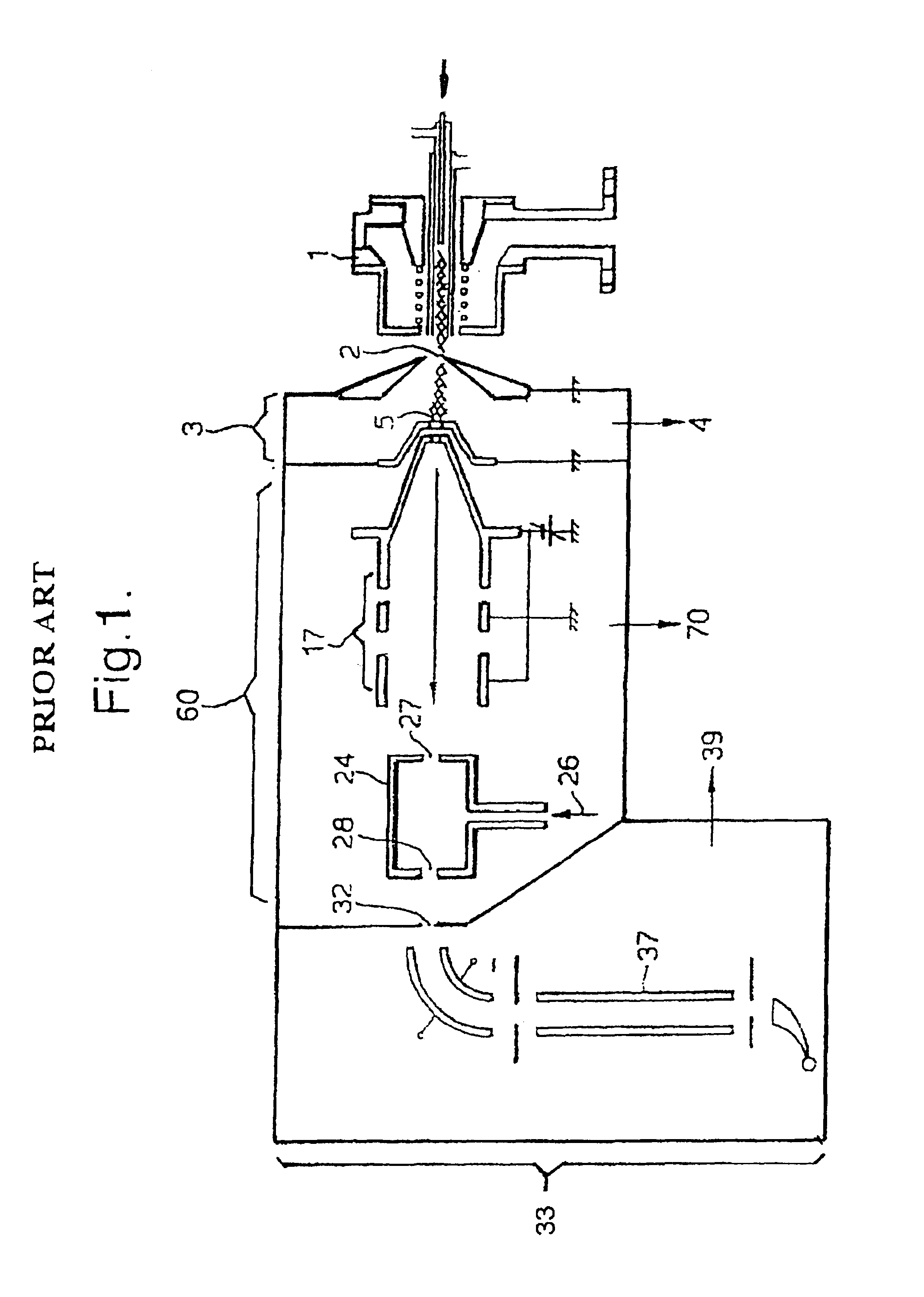

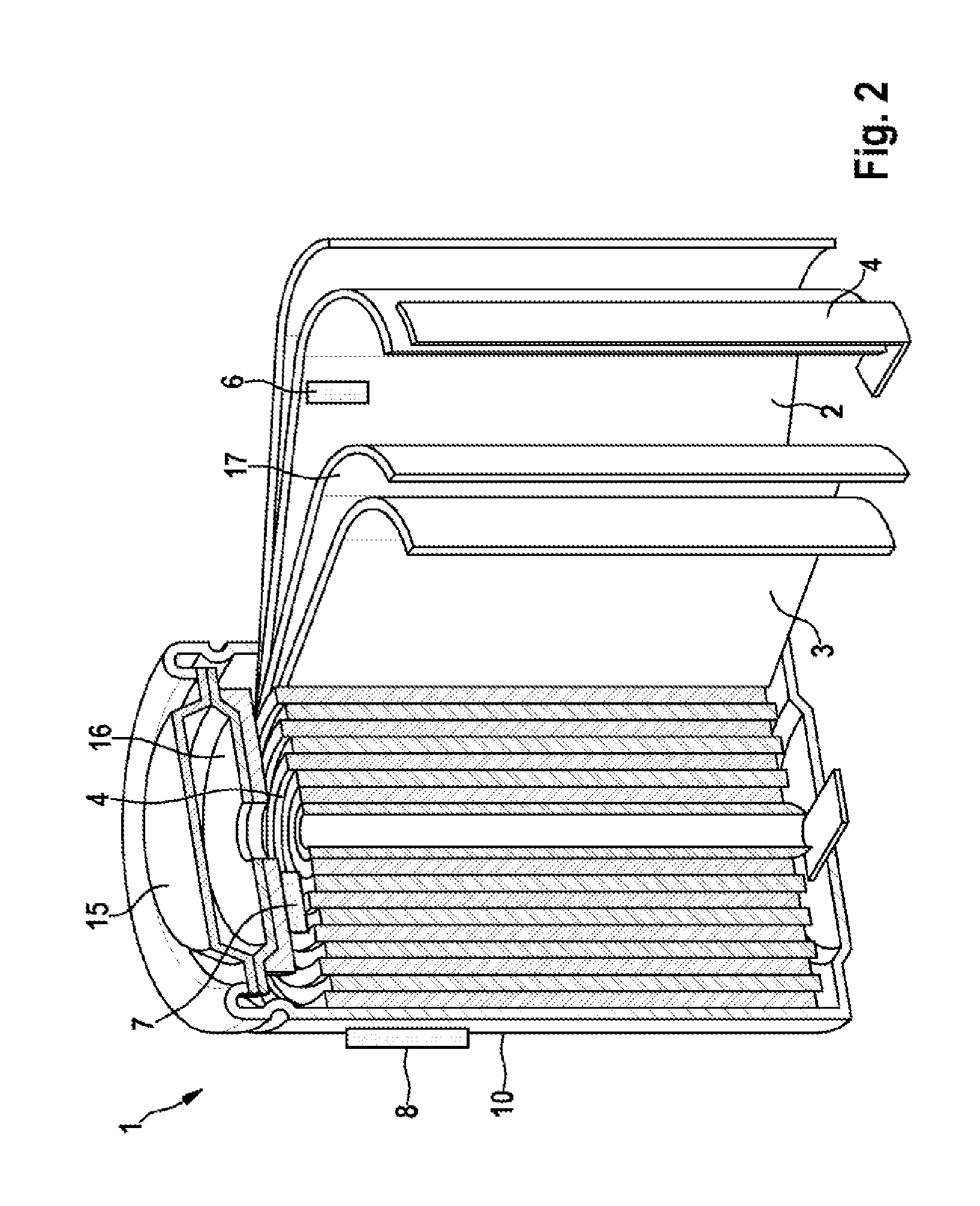

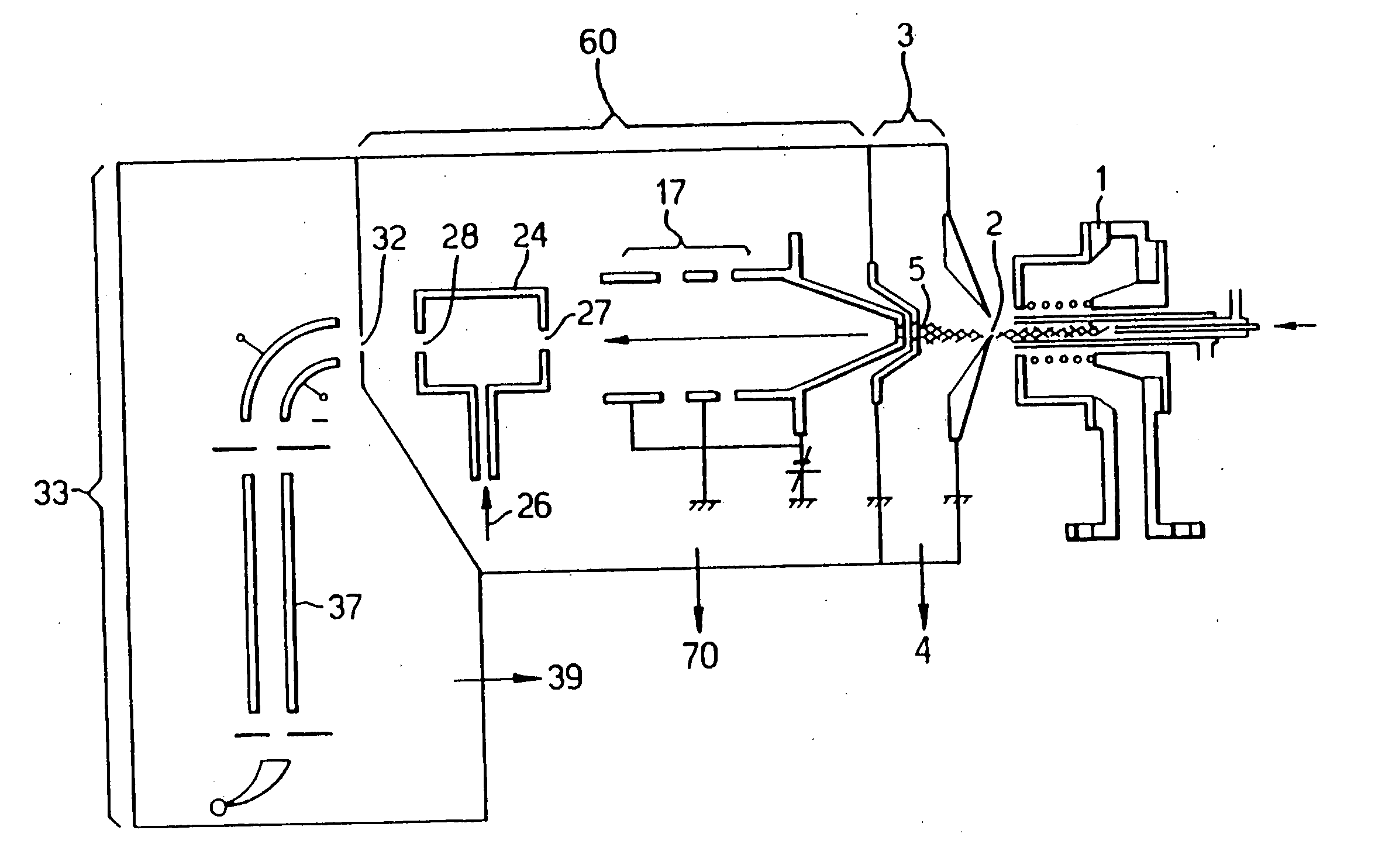

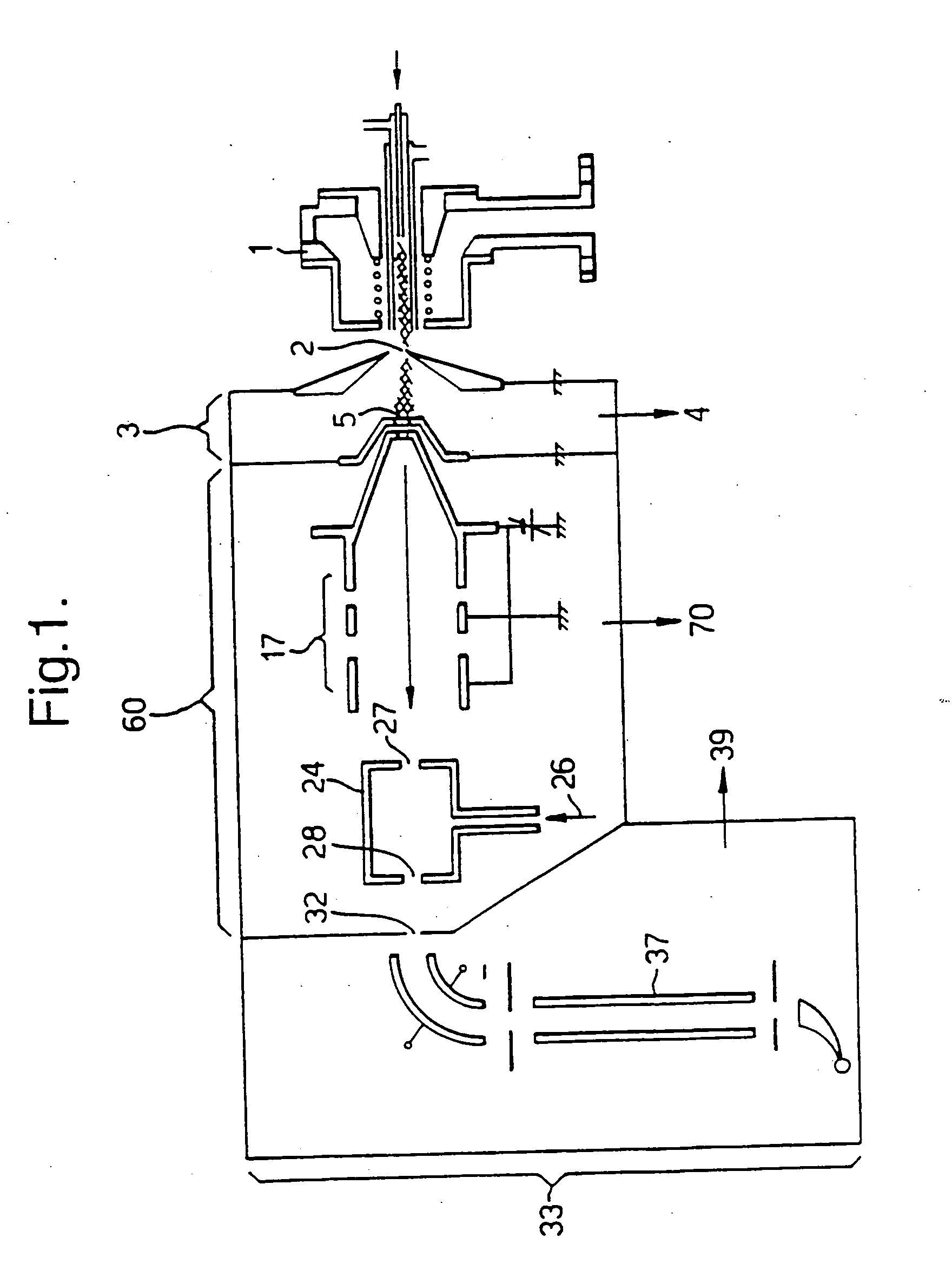

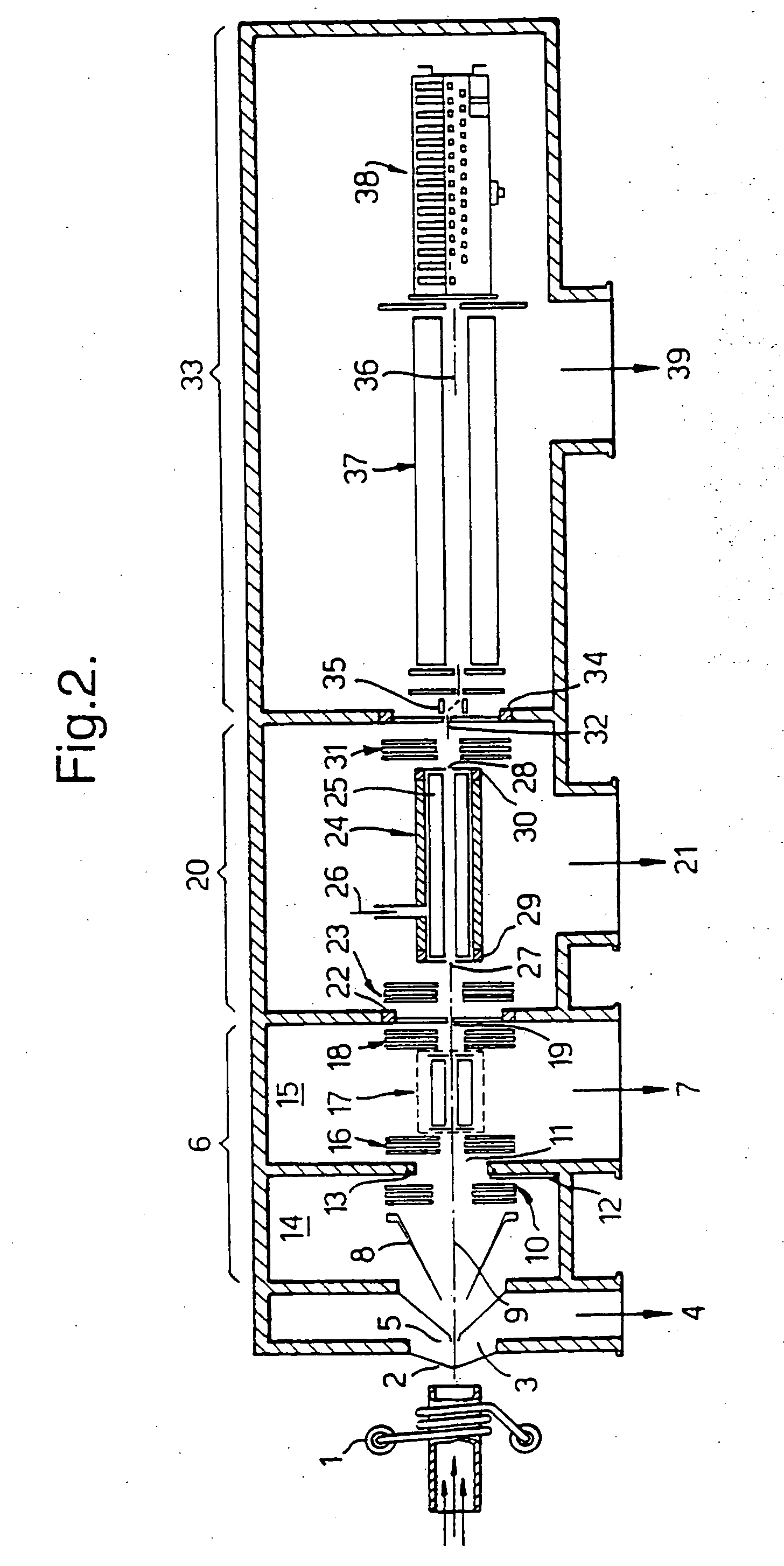

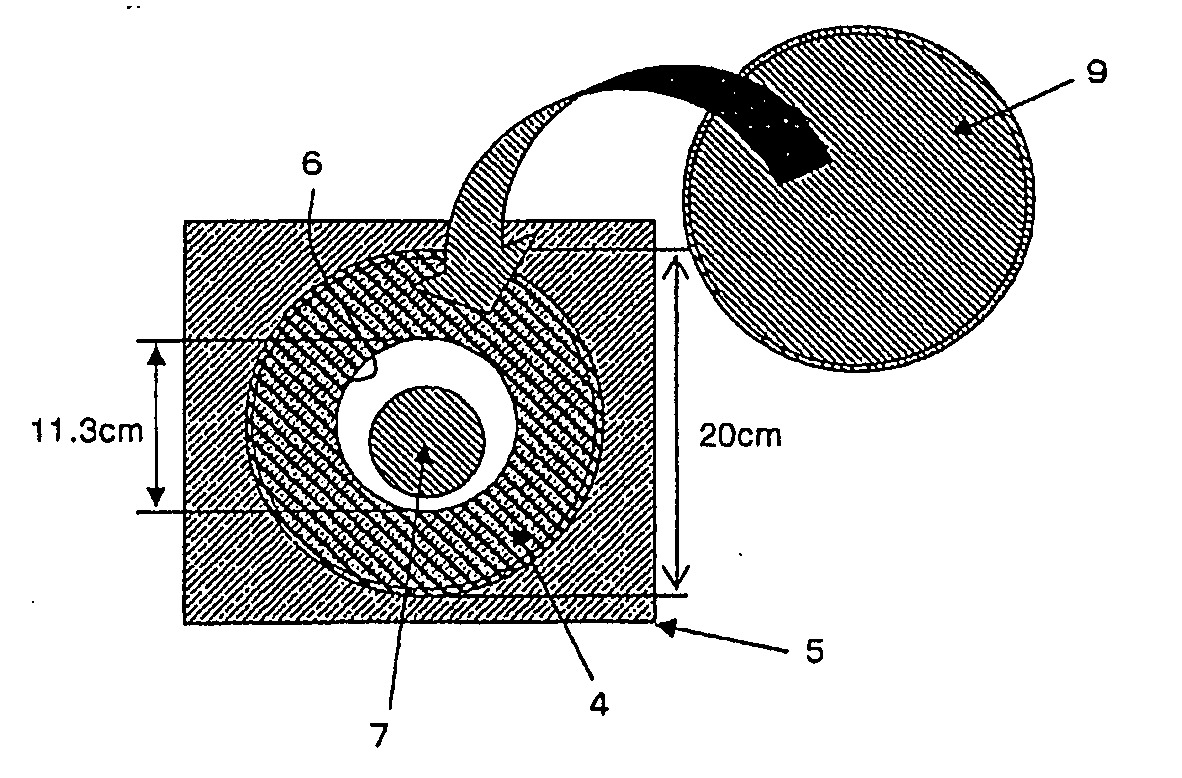

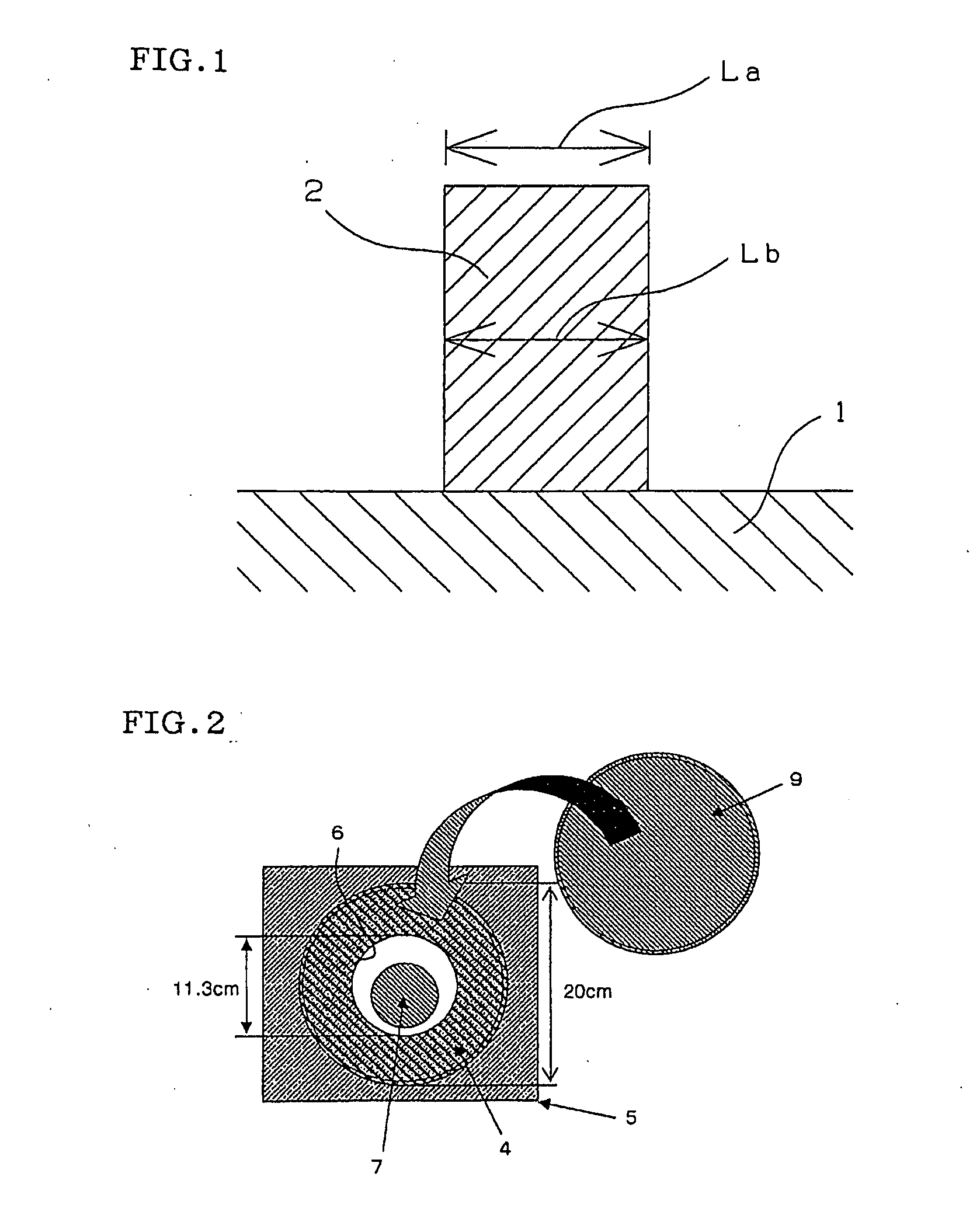

Means for removing unwanted ions from an ion transport system and mass spectrometer

InactiveUS7202470B1Reduce gas loadSufficient transmissionStability-of-path spectrometersSamples introduction/extractionTransport systemIon beam

The present invention relates to inductively coupled plasma mass spectrometry (ICPMS) in which a collision cell is employed to selectively remove unwanted artefact ions from an ion beam by causing them to interact with a reagent gas. The present invention provides a first evacuated chamber (6) at high vacuum located between an expansion chamber (3) and a second evacuated chamber (20) containing the collision cell (24). The first evacuated chamber (6) includes a first ion optical device (17). The collision cell (24) contains a second ion optical device (25). The provision of the first evacuated chamber (5) reduces the gas load on the collision cell (24), by minimising the residual pressure within the collision cell (24) that is attributable to the gas load from the plasma source (1). This serves to minimise the formation, or re-formation, of unwanted artefact ions in the collision cell (24).

Owner:THERMO FISHER SCI BREMEN +1

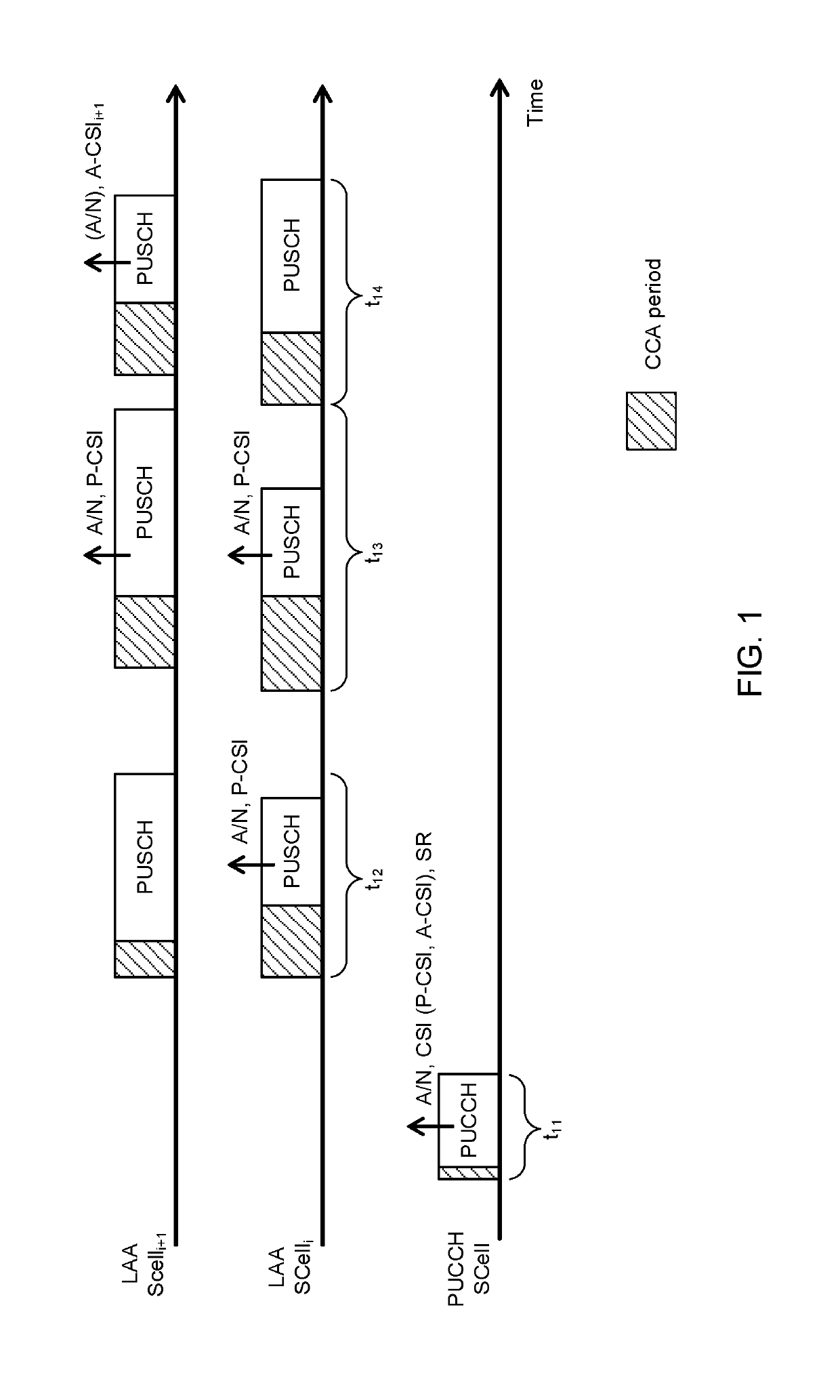

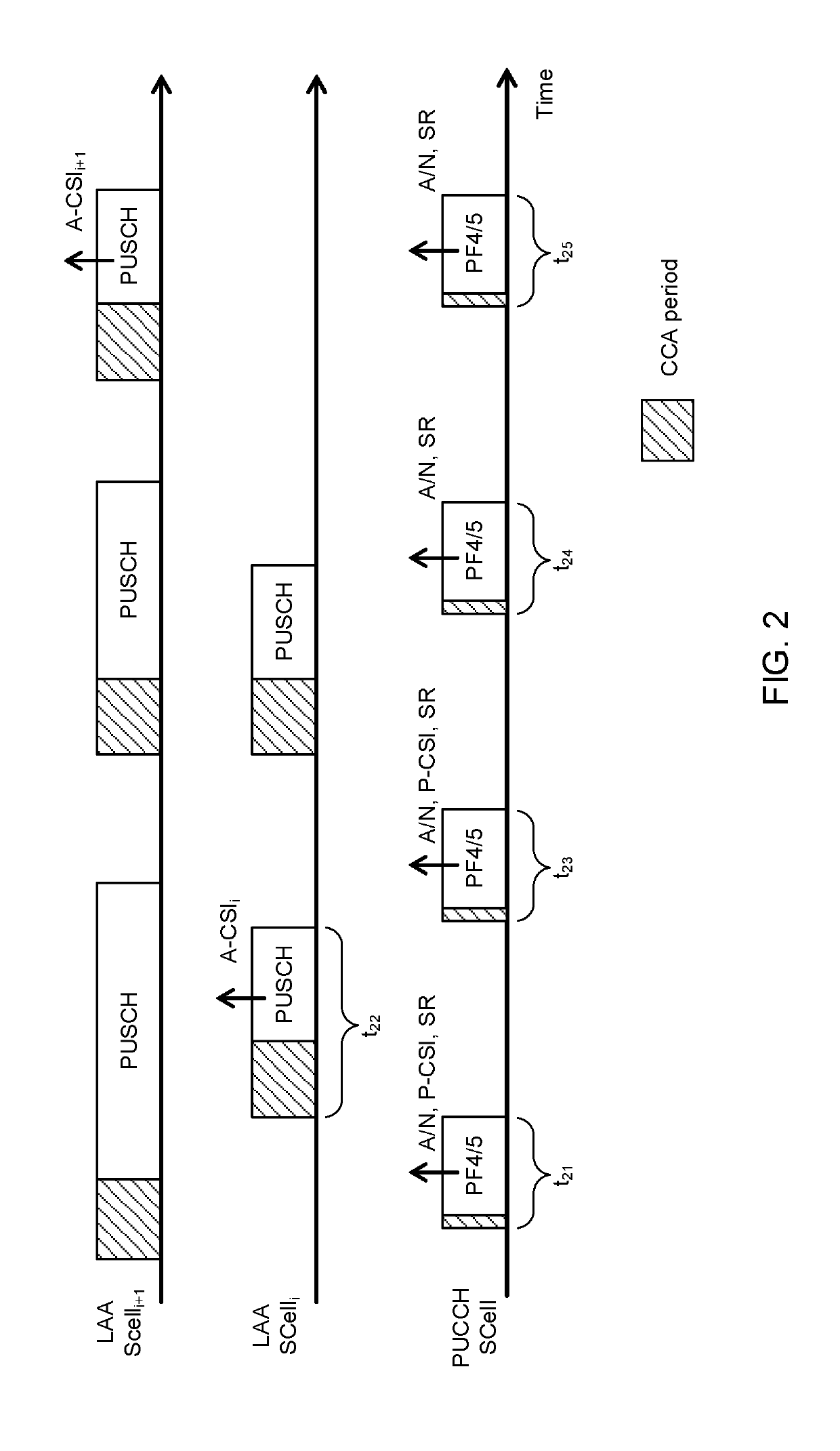

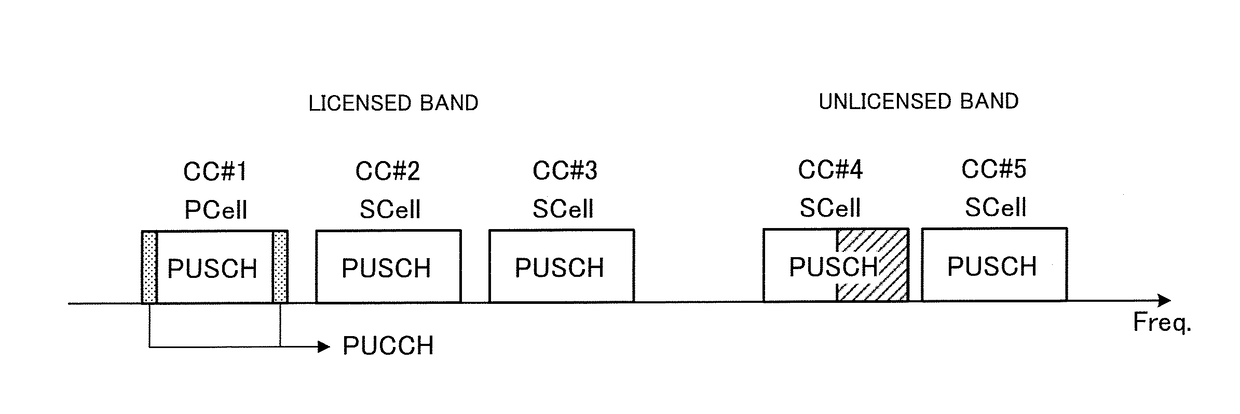

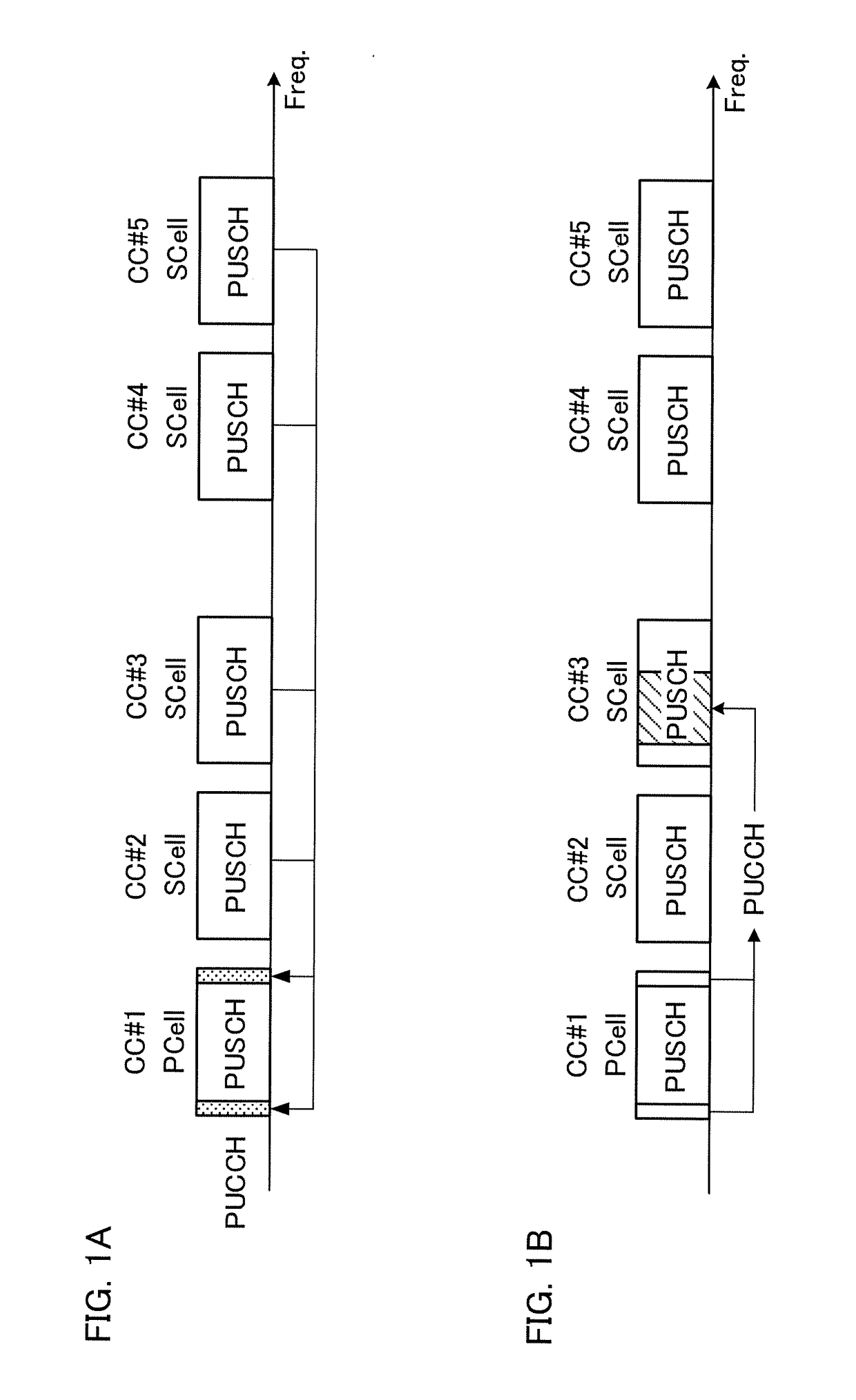

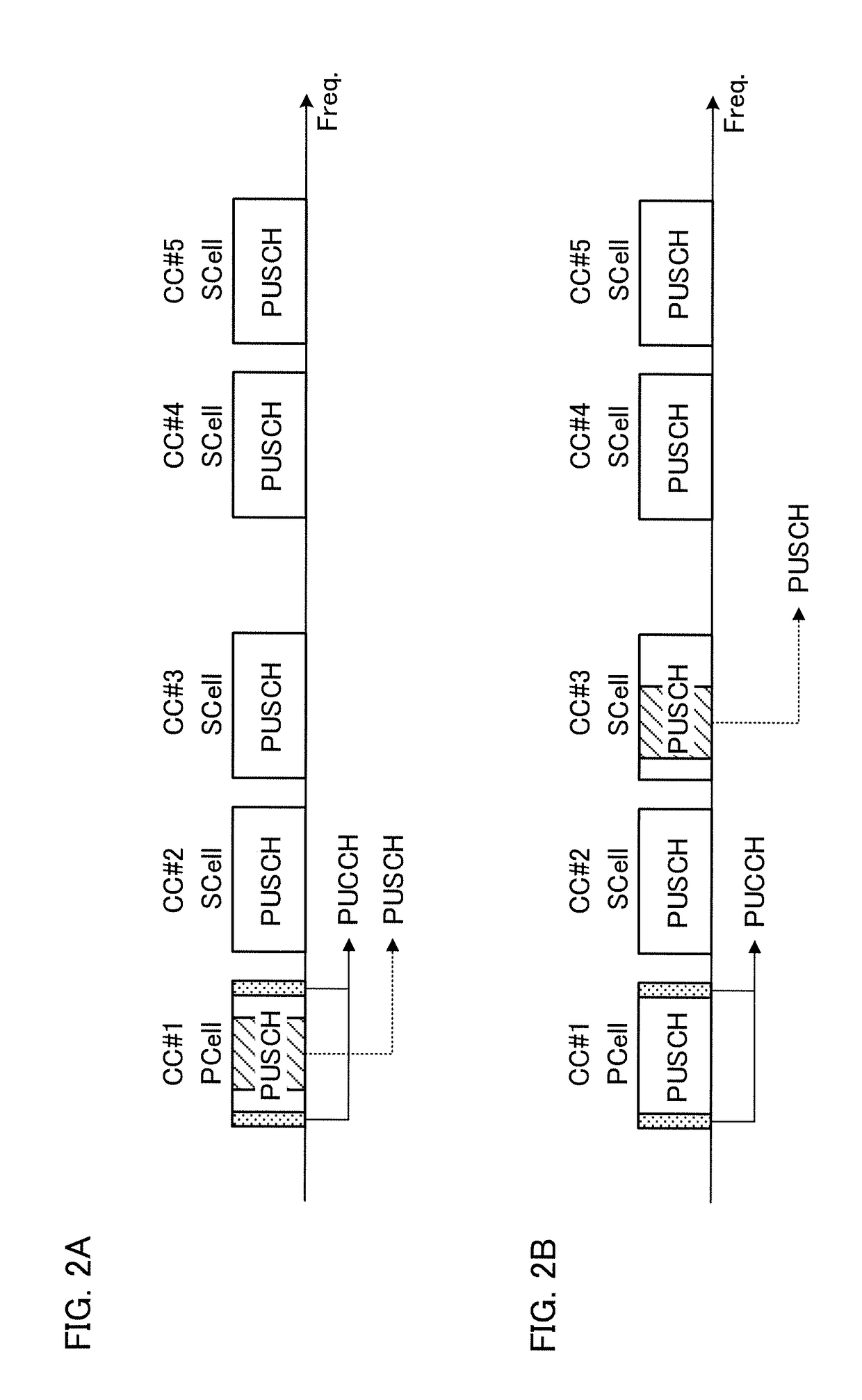

User terminal, radio base station and radio communication method

InactiveUS20190116489A1Sufficient transmissionNetwork planningNetwork data managementUplink transmissionCarrier signal

The present invention is designed to suitably realize UCI (Uplink Control Information) transmission at a desired timing in a carrier where LBT (Listen Before Talk) is configured. A user terminal, according to one embodiment of the present invention, has a transmission section that transmits signals in carriers where listening is performed before uplink transmission, a receiving section that receives PUCCH cell configuration information as to whether or not at least one of the carriers is a cell where a PUCCH (Physical Uplink Control Channel) is transmitted, and a control section that controls the transmission of uplink control information (UCI) in the carriers based on the PUCCH cell configuration information.

Owner:NTT DOCOMO INC

User terminal, radio base station and radio communication method

InactiveUS20180084540A1Adequate UL transmissionSufficient transmissionSpectral gaps assessmentTransmission path divisionCommunication qualityControl channel

The present invention is designed so that UL transmission can be carried out adequately even when communication is carried out by using a plurality of CCs of varying communication qualities. A user terminal communicates with a radio base station by using a first CC and a second CC, and has a generating section that generates uplink control information based on DL signals transmitted from the radio base station, a transmission section that transmits uplink control information, and a control section that controls the transmission of the uplink control information, wherein, when transmission of an uplink shared channel is indicated in the first CC, the control section controls the transmission of the uplink control information by using the uplink shared channel of the first CC, and, when transmission of an uplink shared channel is indicated in the second CC and the transmission of the uplink shared channel is not indicated in the first CC, the control section controls the transmission of the uplink control information by using an uplink control channel of the first CC.

Owner:NTT DOCOMO INC

Surgical operation device

InactiveUS7572253B2Microsurgery to be easilyEasy to implementSuture equipmentsMechanical apparatusSurgical operationEngineering

In order to rotate and move an arm of a slave which supports a needle-holder, the rotation and movement of a pen-shaped operating section (31) caused by the fingers of the operator's hand are directly transmitted as the rotation and movement of the needle-holder, as sensors for detecting the rotation and movement of the operating section, an X-axis torque sensor, Y-axis torque sensor, Z-axis torque sensor, and a rotation detecting potentiometer (33) are installed thereon. As a result, the rotation and movement of the pen-shaped operating section (31) caused by the fingers of the operator's hand are transmitted as the rotation and movement of the needle-holder in optimum proportions through a computing section. Therefore, when the needle-holder is to be finely moved, a subtle motion of the fingers of the hand can be satisfactorily transmitted. Thereby, it is possible to provide a surgical operation device capable of doing minute surgical operations with ease.

Owner:JAPAN SCI & TECH CORP

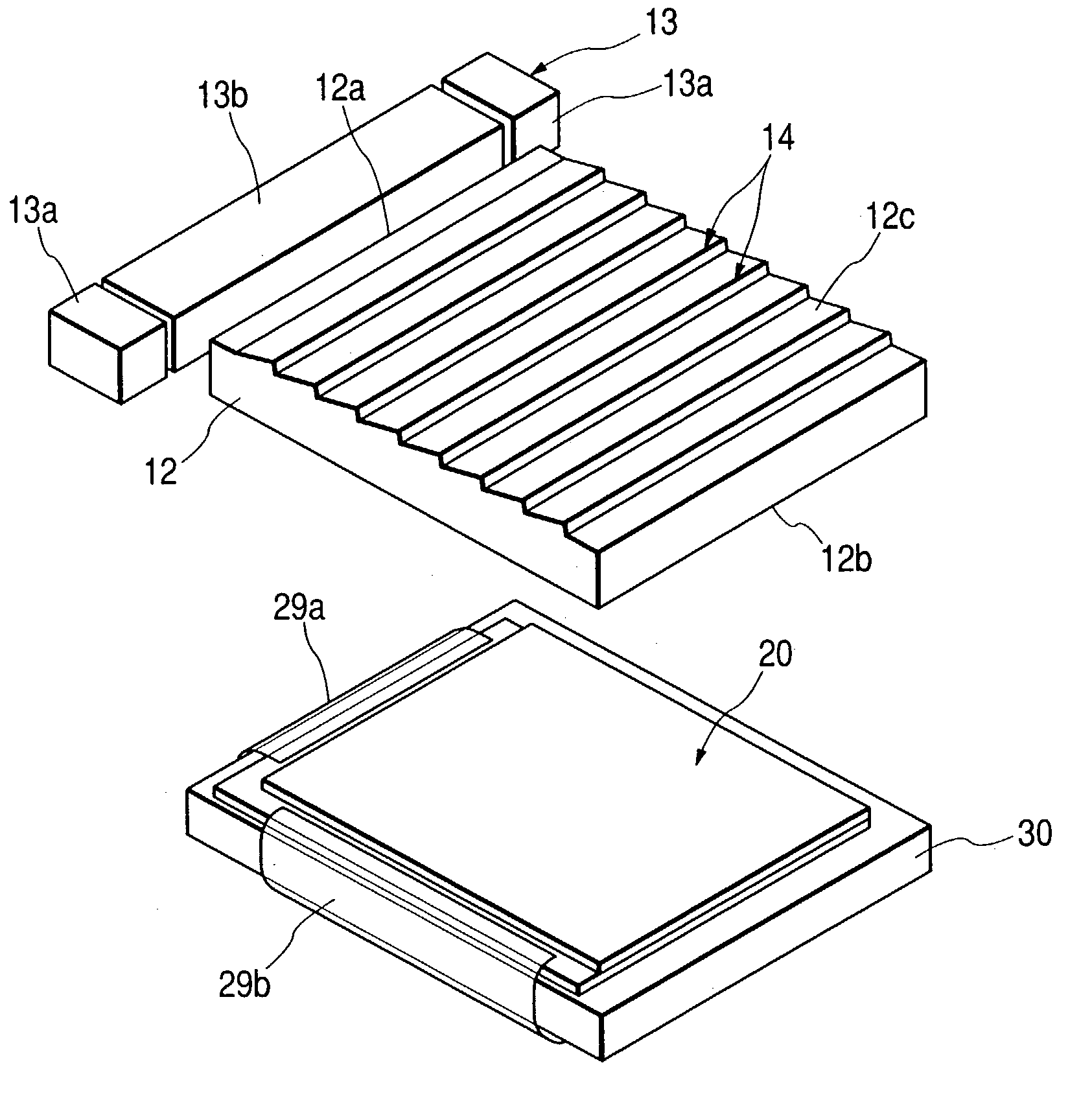

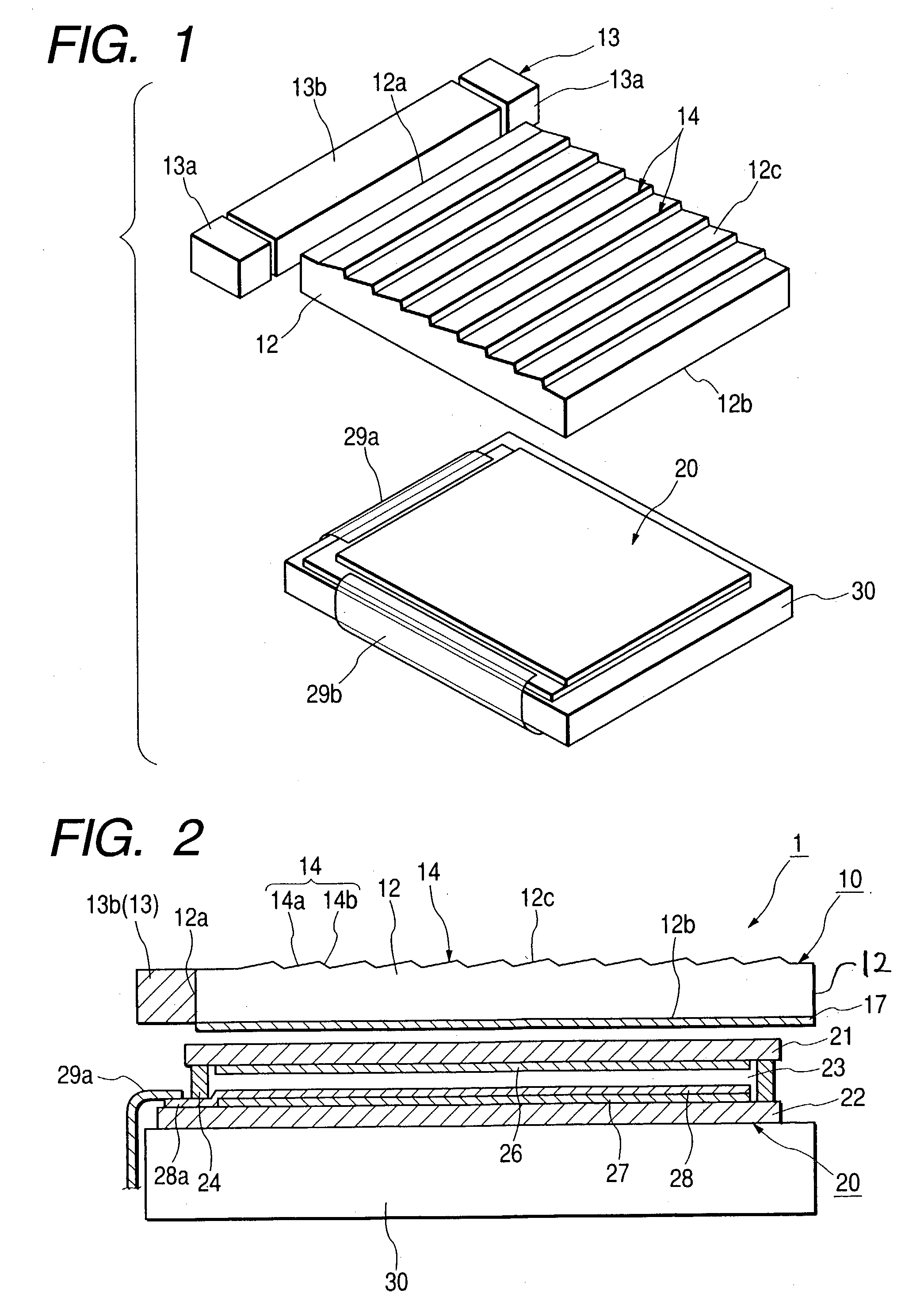

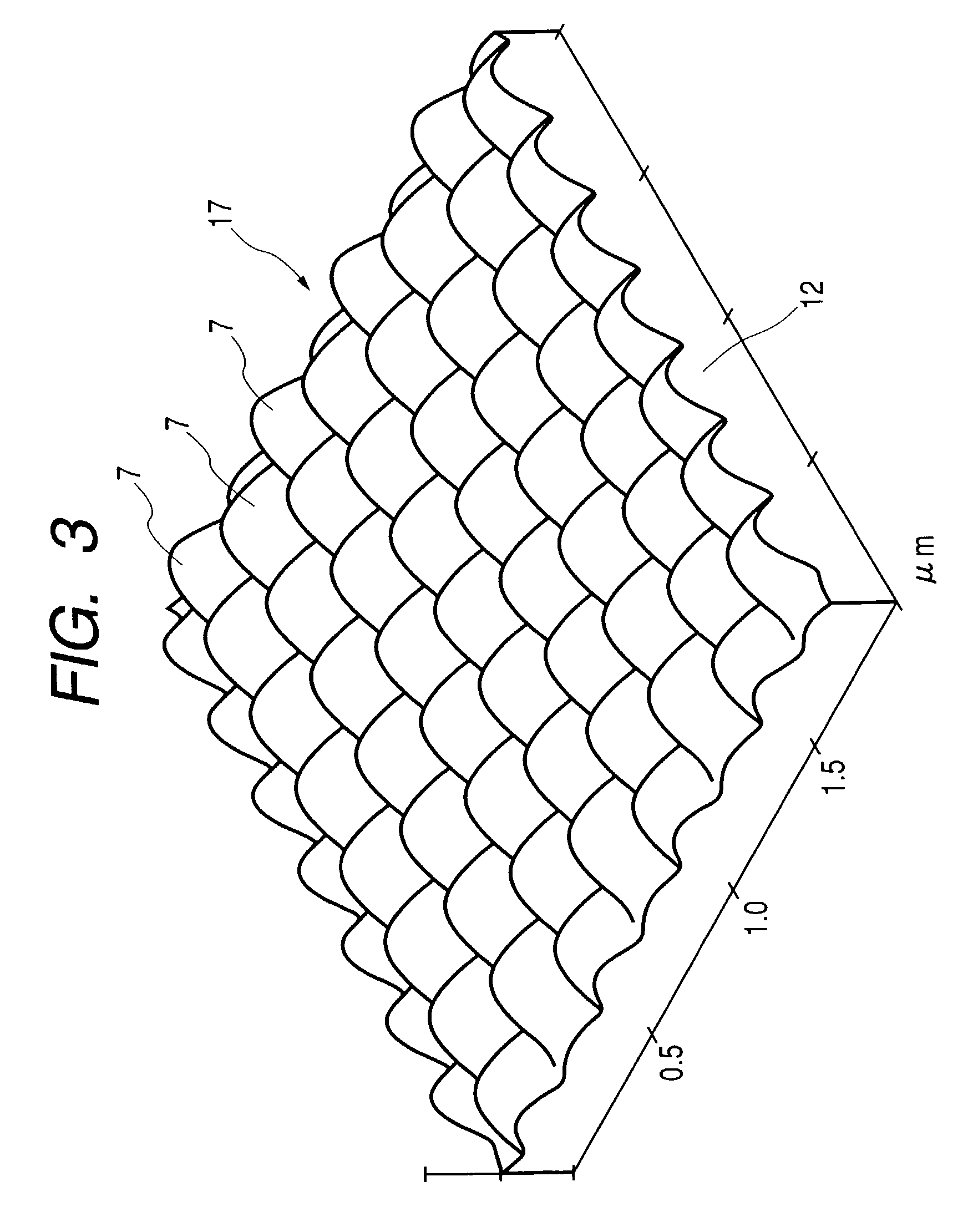

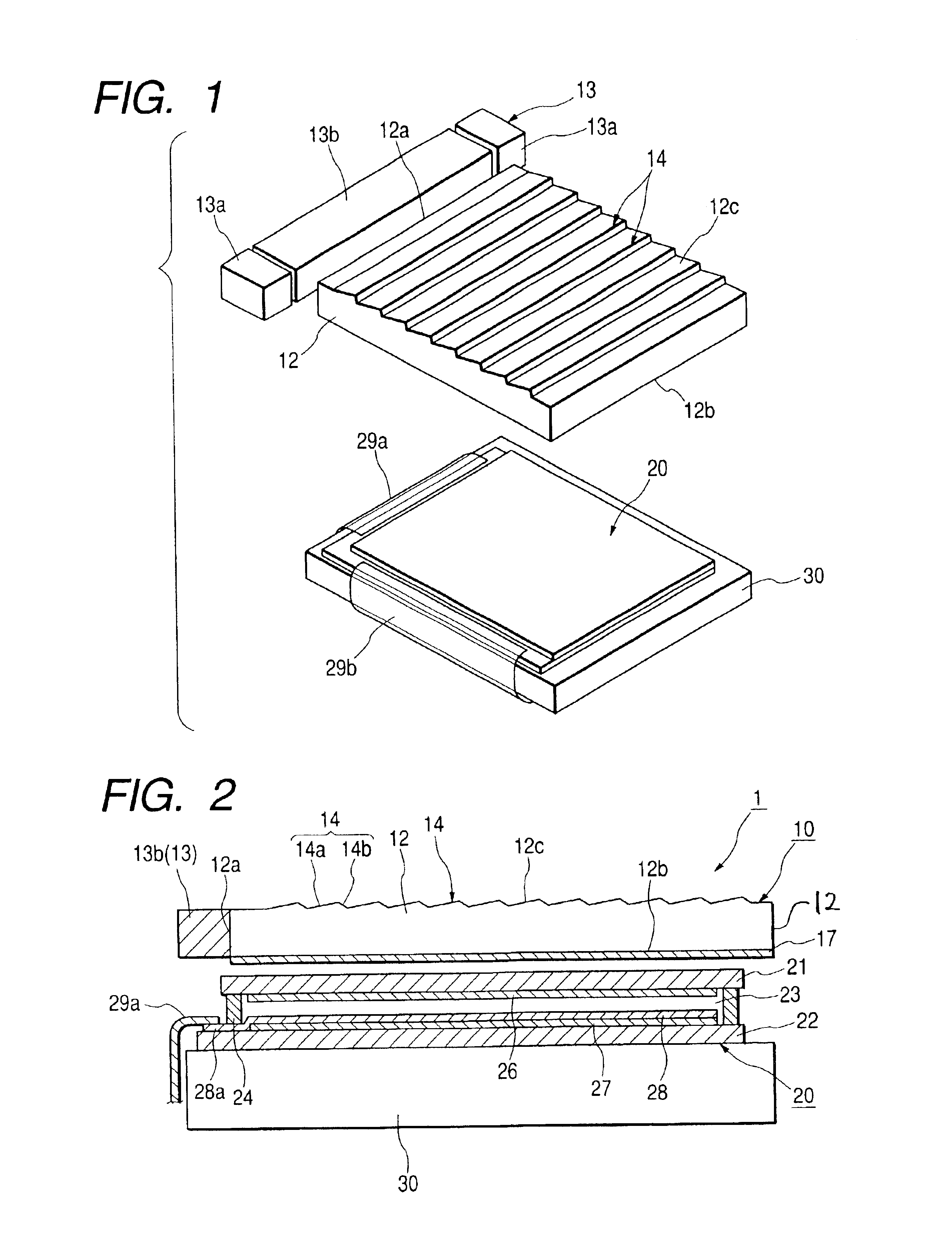

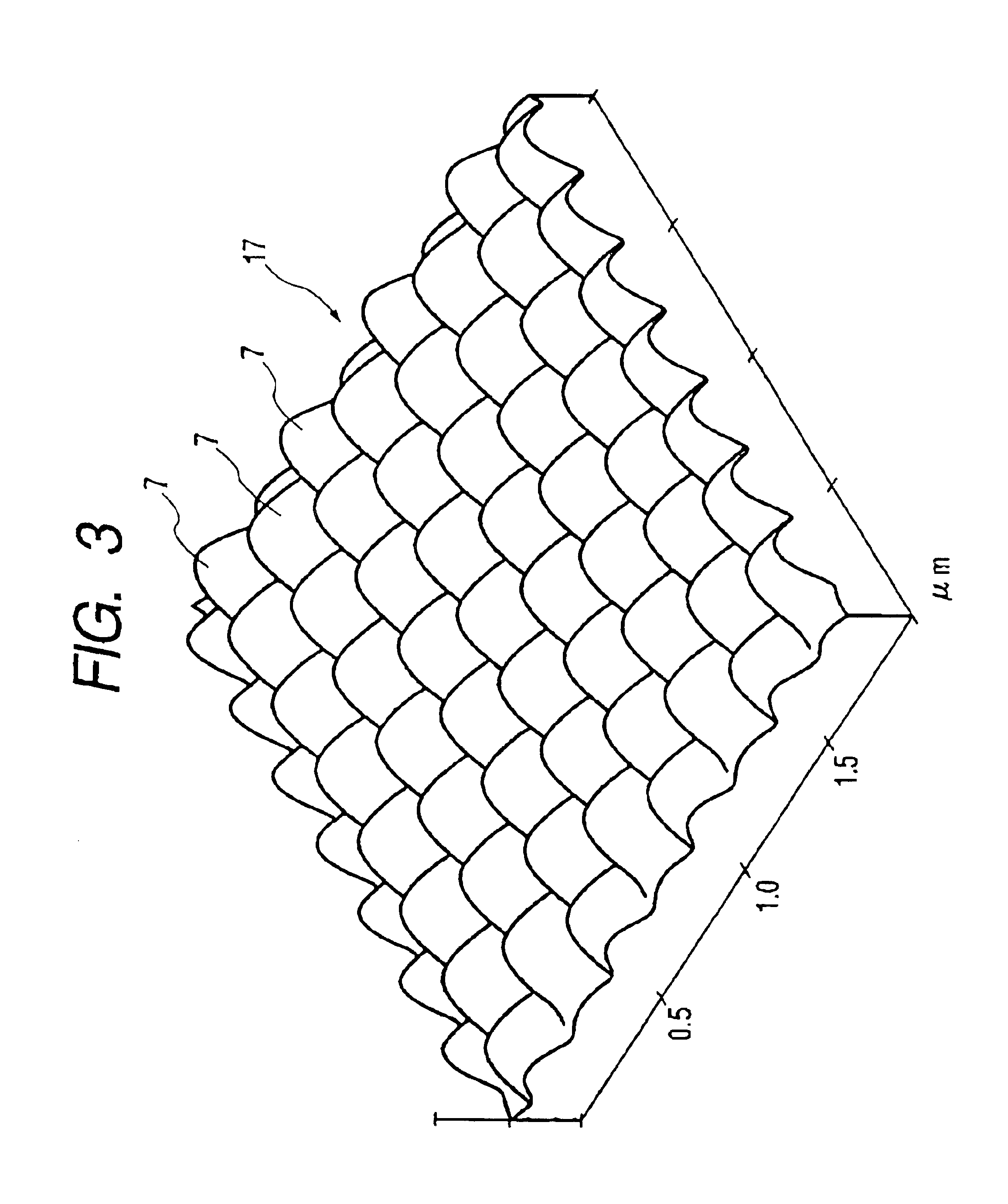

Light guide plate having anti-reflection layer and a method of manufacturing the same

InactiveUS20030123244A1Reduce transmittanceSufficient transmissionMeasurement apparatus componentsDiffusing elementsLight guideOptoelectronics

A light guide plate includes a light guide positioned to receive light from a light source at a side end face. The light guide includes an exit surface that conveys light from the guide plate. Preferably, the exit surface has an anti-reflection layer having microscopic recesses or projections arranged in a lattice.

Owner:ALPS ALPINE CO LTD

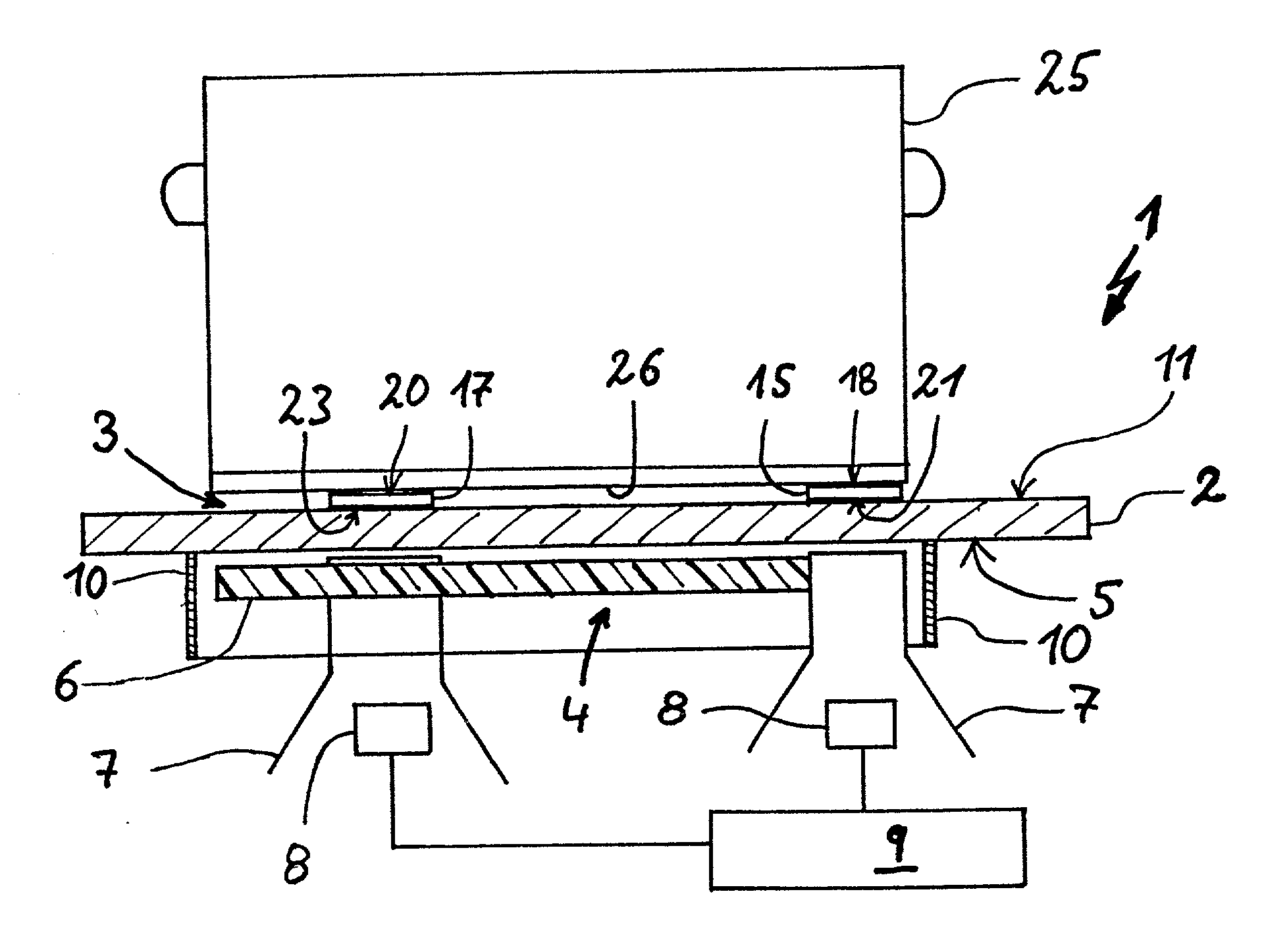

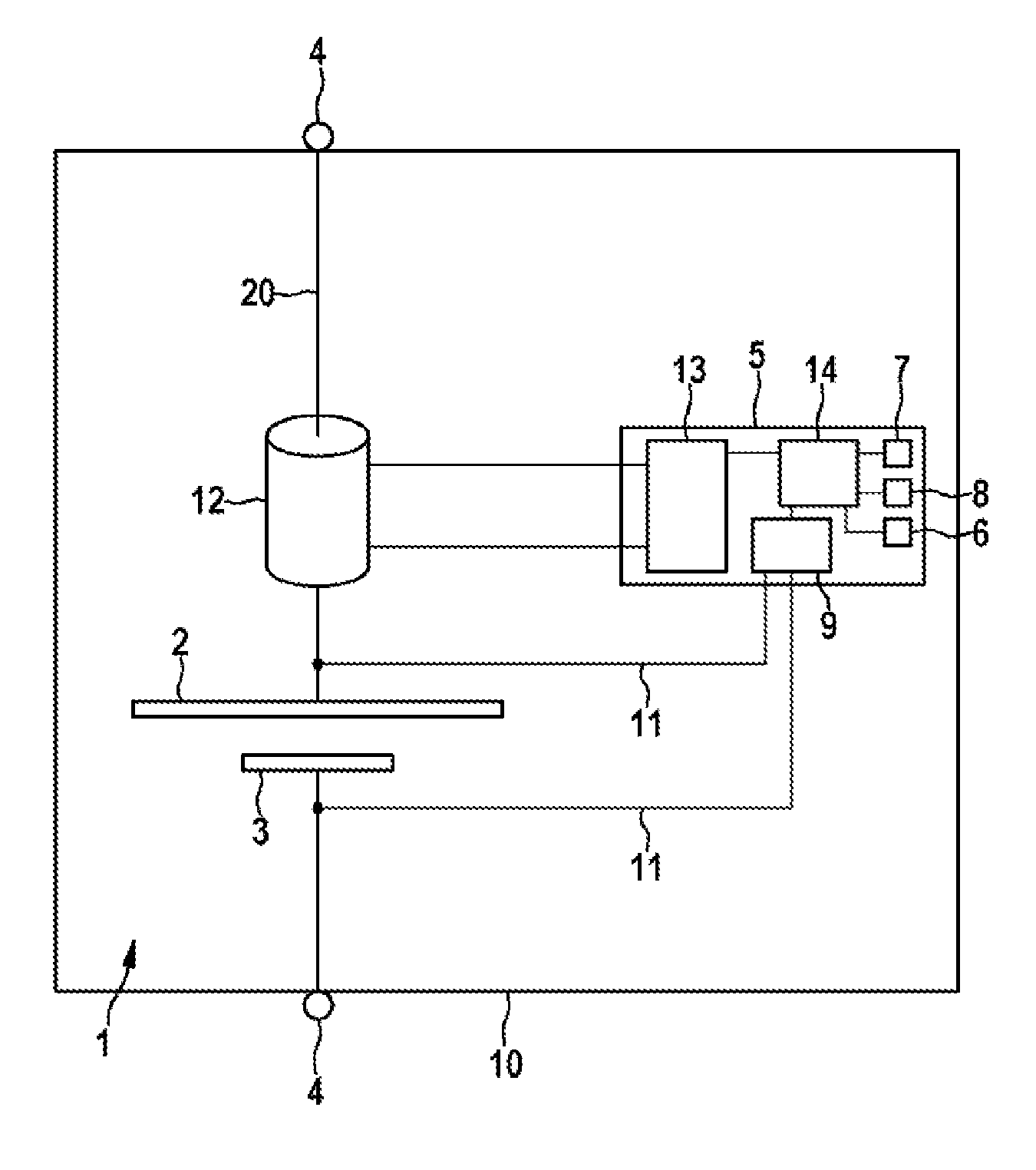

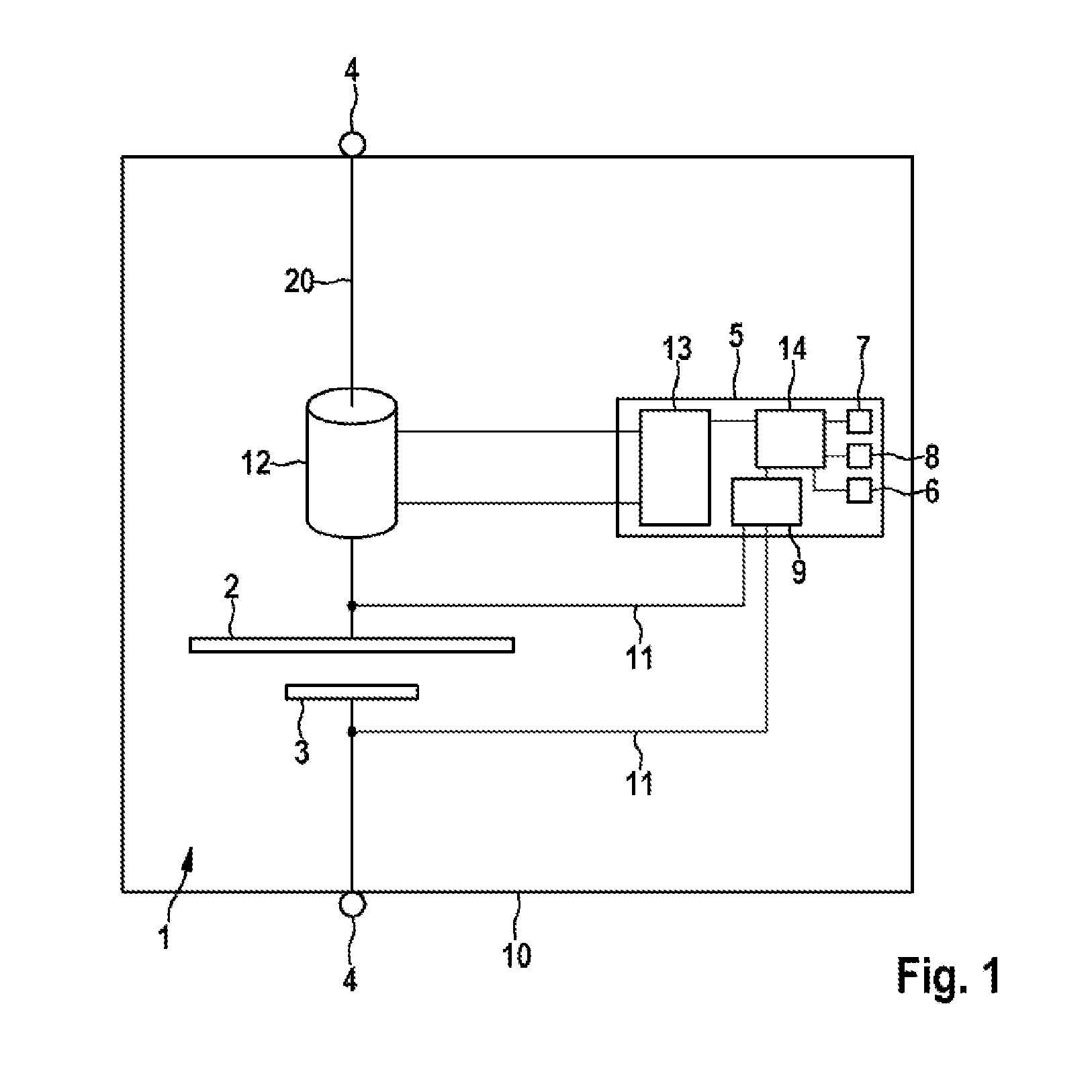

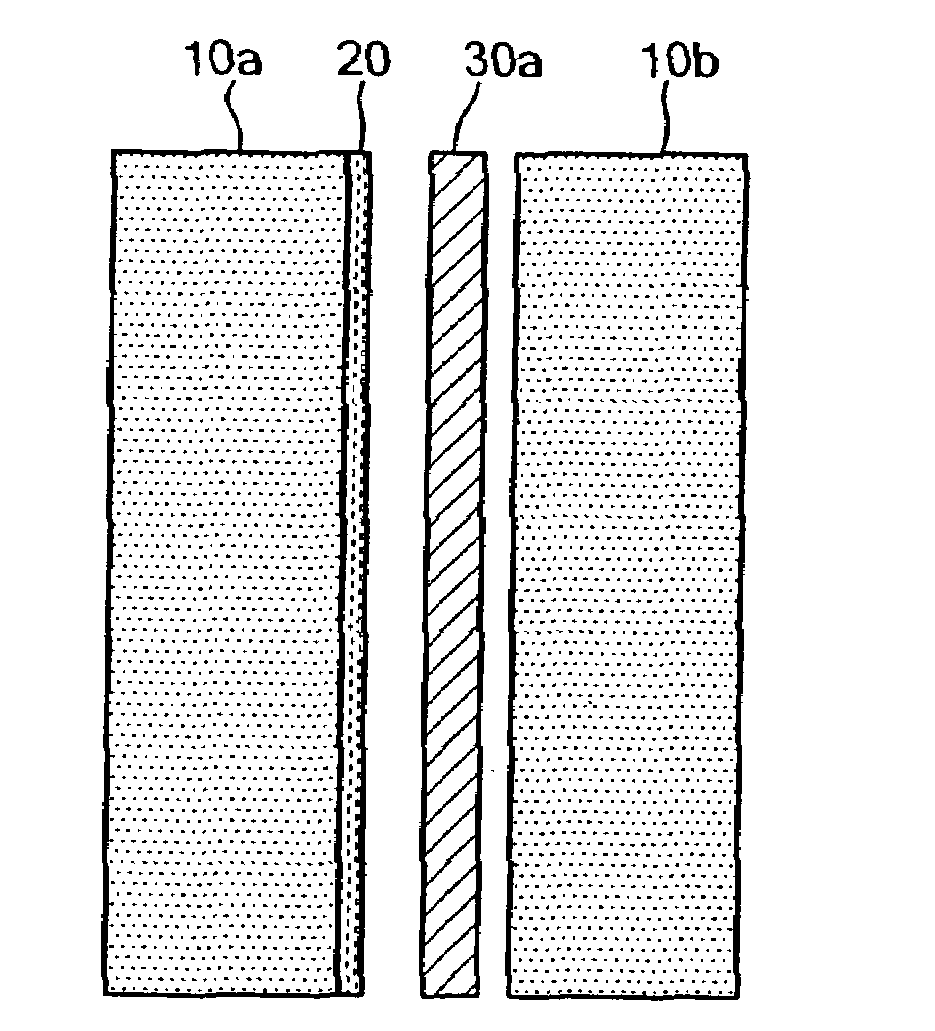

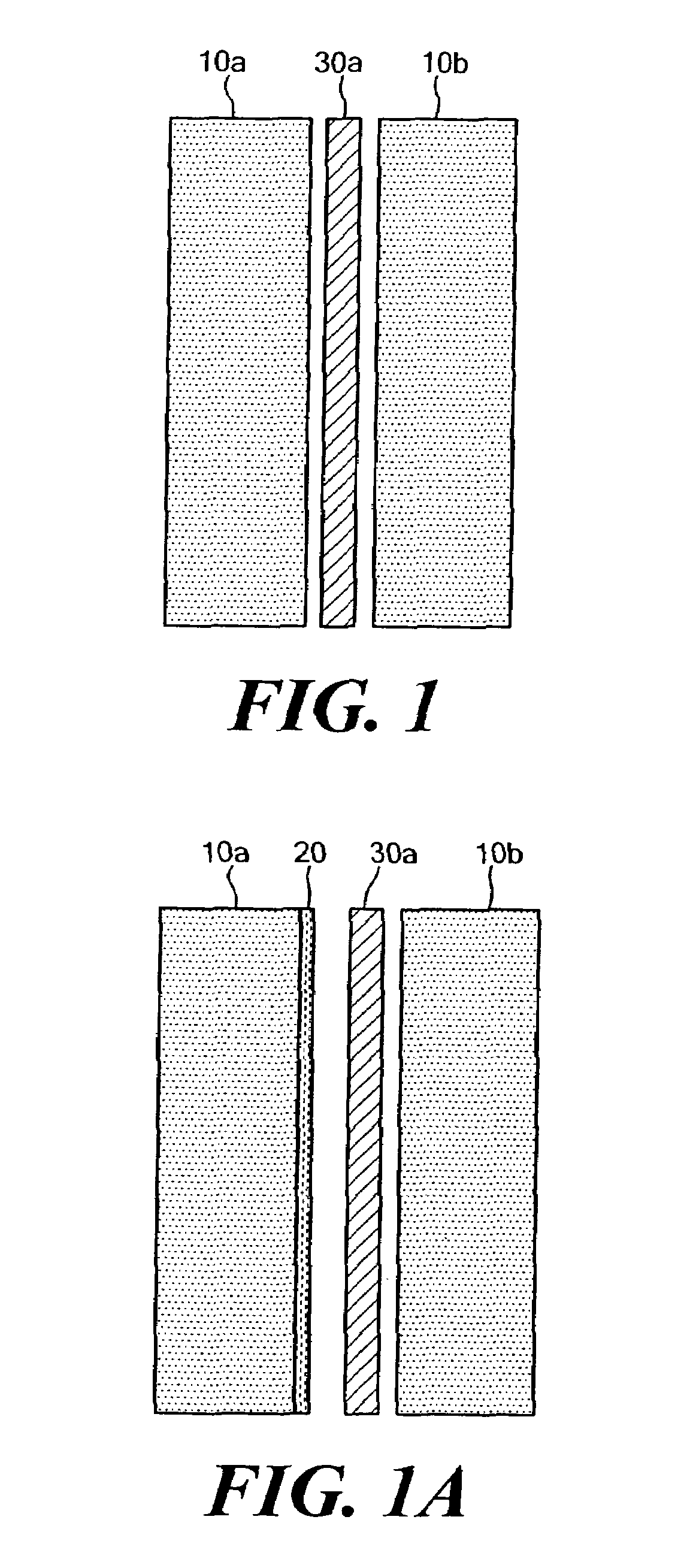

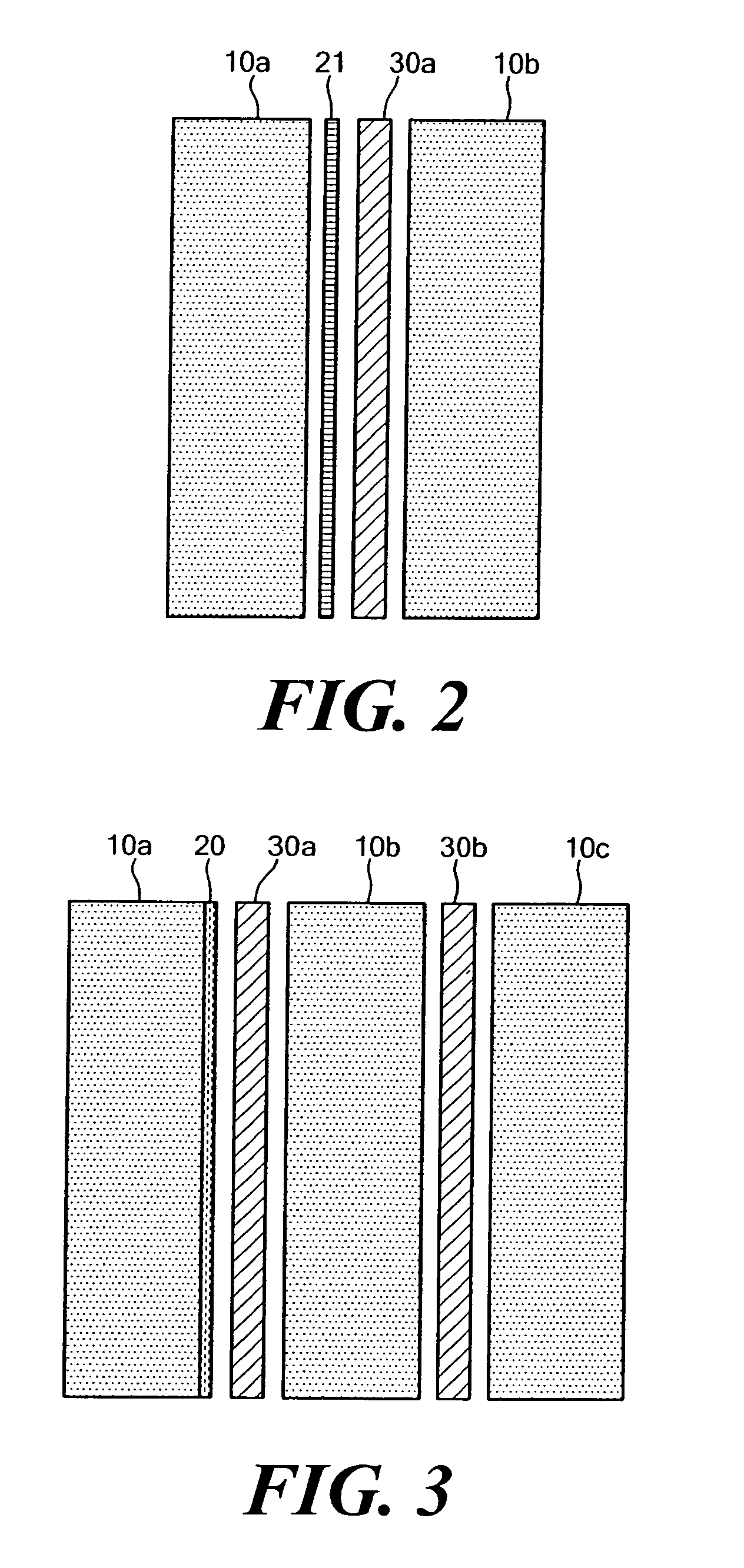

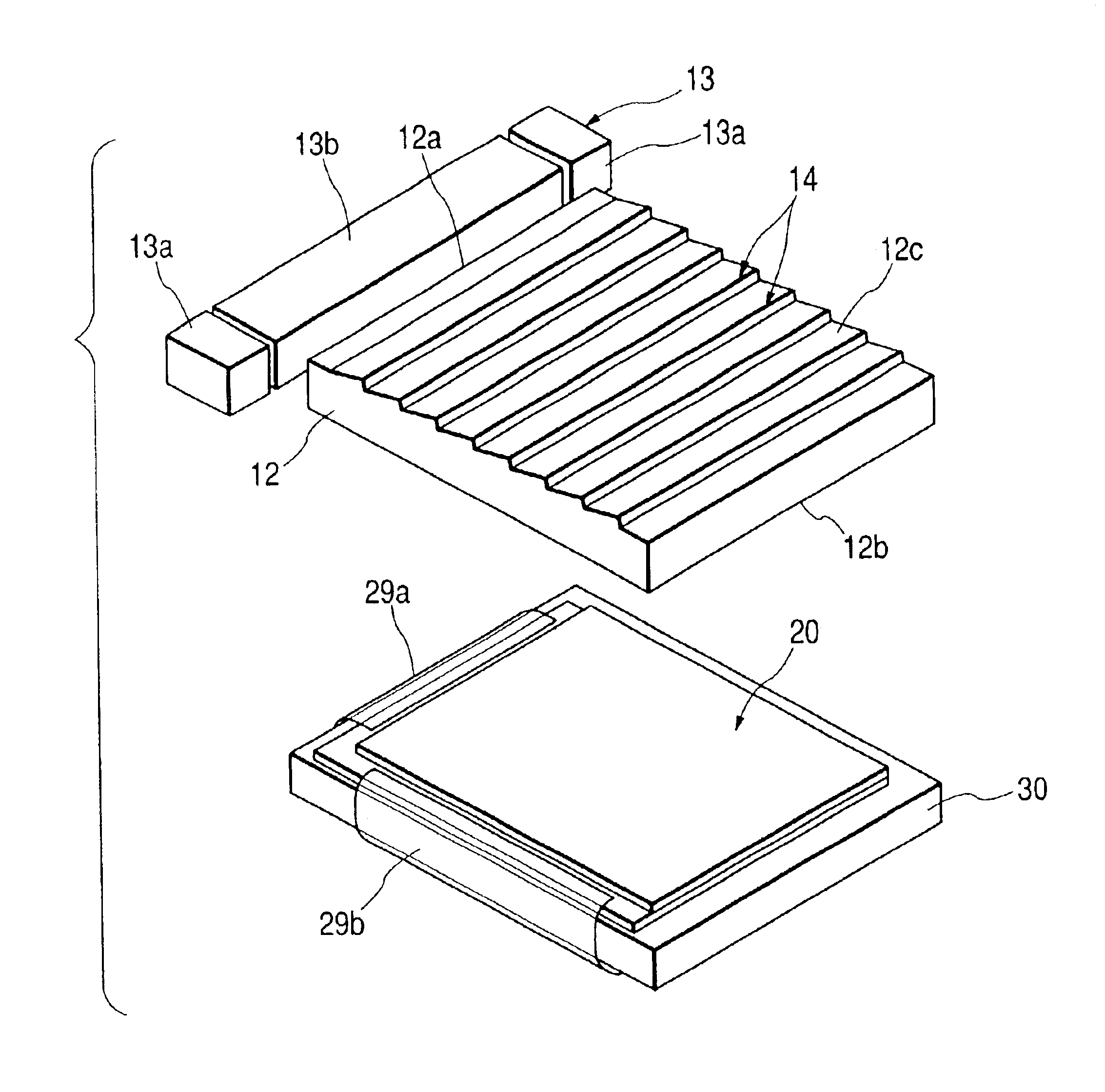

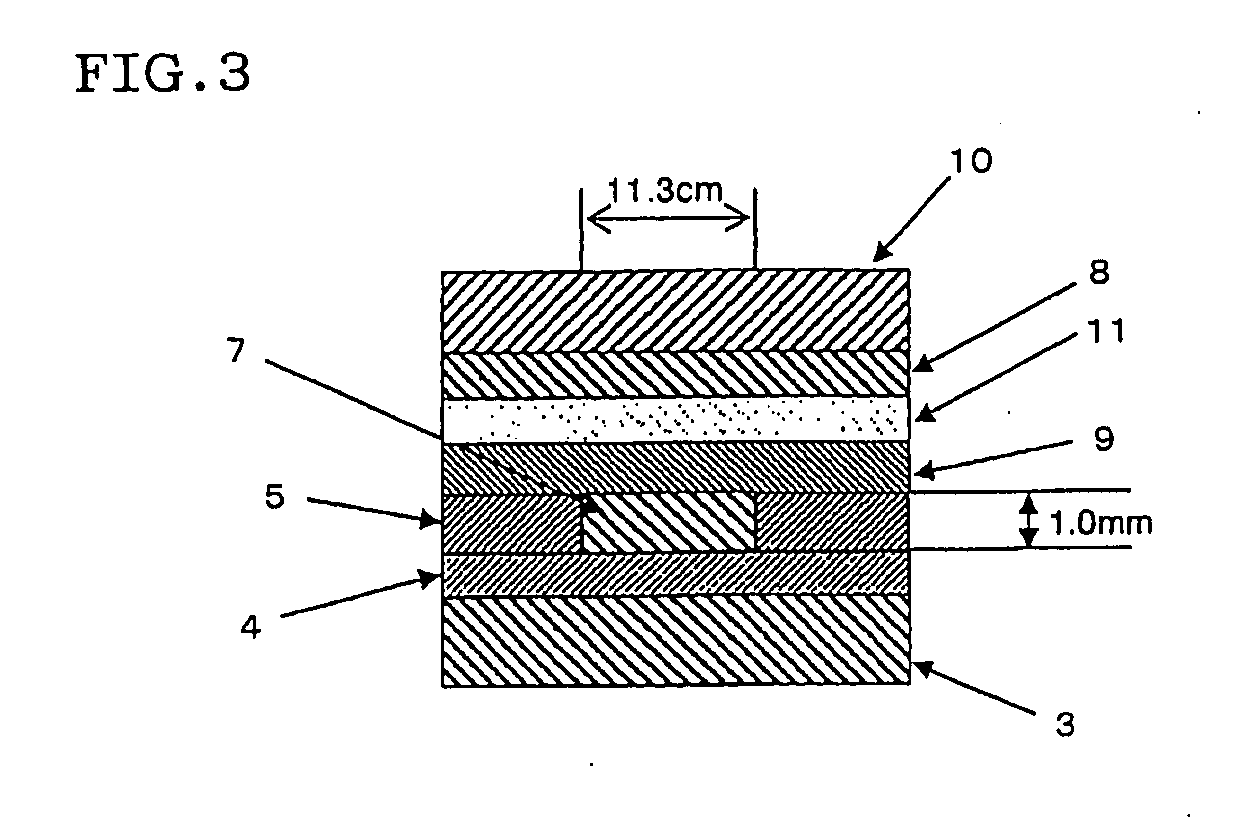

Battery cell comprising a device for monitoring at least one parameter of the battery cell

InactiveUS20150311571A1Improve monitoring of parameterSmooth connectionBatteries circuit arrangementsFinal product manufactureEngineeringLithium-ion battery

The invention relates to a battery cell (1), in particular a lithium-ion cell, having at least one positive electrode (2), at least one negative electrode (3) and connections (4) which are connected in an electrically conductive manner to the electrodes (2, 3) for electrically contacting the battery cell (1). The battery cell (1) comprises a device (5) for monitoring at least one parameter of the battery cell (1) and the device (5) comprises at least one sensor (6, 7, 8, 9).

Owner:ROBERT BOSCH GMBH

Photochromic film material

InactiveUS7273659B2Long useful lifeLonger effective lifetimePhotosensitive materialsSynthetic resin layered productsHeat stabilityNear infrared radiation

The invention is directed to a photochromic material that filters, from solar radiation, near infrared radiation and sufficient portions of ultraviolet radiation while transmitting actinic radiation in the wavelength range of about 341±5 nm. The light-transmitting photochromic material provides light and heat stability to achieve a longer useful life. This photochromic material is preferably incorporated in a multilayered structure with constituents provided on or contained within one or more layers to enhance the resistance to light fatigue.

Owner:LINTEC CORP

Light guide plate having anti-reflection layer and a method of manufacturing the same

InactiveUS6808282B2Reduce transmittanceSufficient transmissionMeasurement apparatus componentsDiffusing elementsLight guideOptoelectronics

A light guide plate includes a light guide positioned to receive light from a light source at a side end face. The light guide includes an exit surface that conveys light from the guide plate. Preferably, the exit surface has an anti-reflection layer having microscopic recesses or projections arranged in a lattice.

Owner:ALPS ALPINE CO LTD

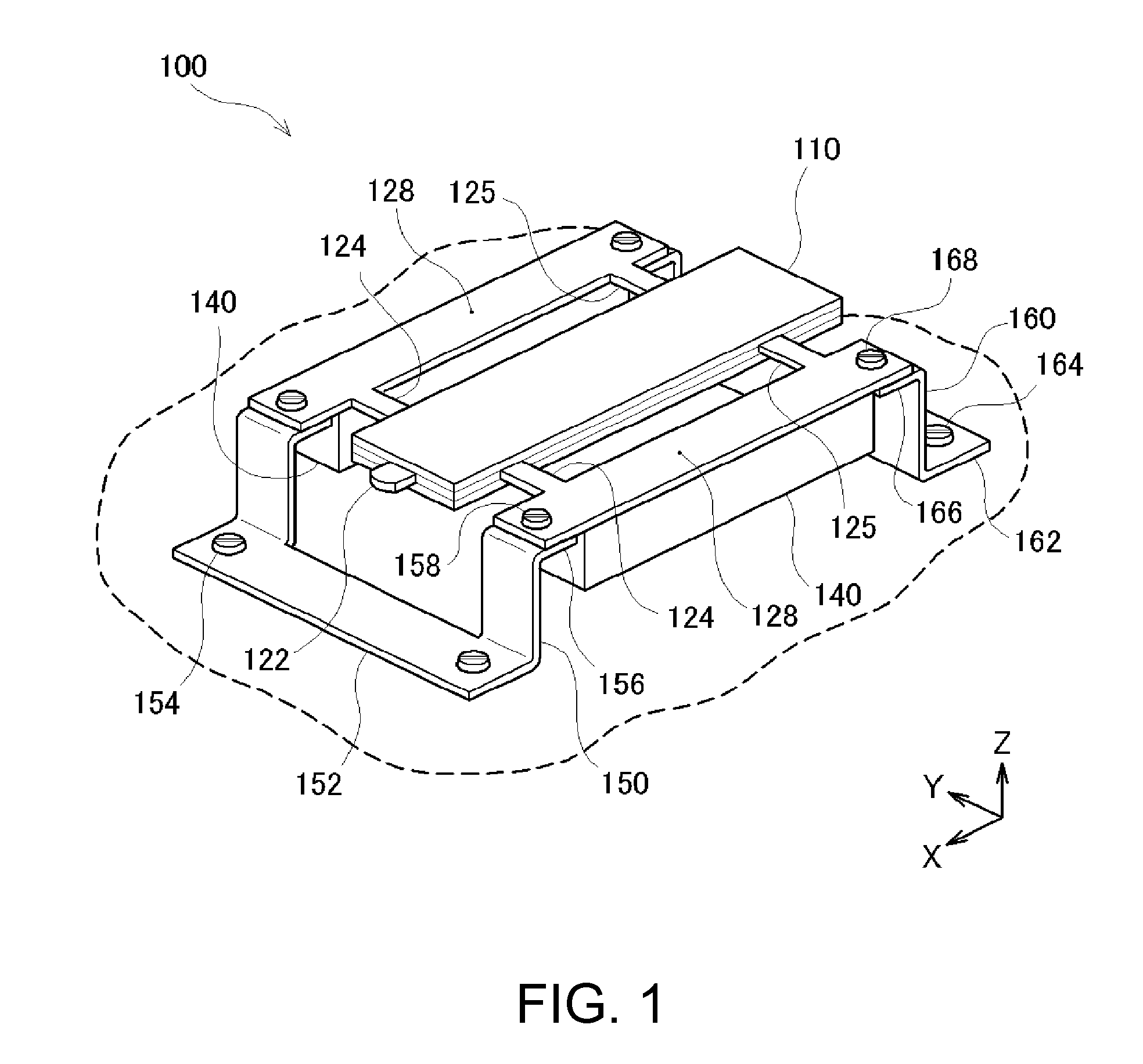

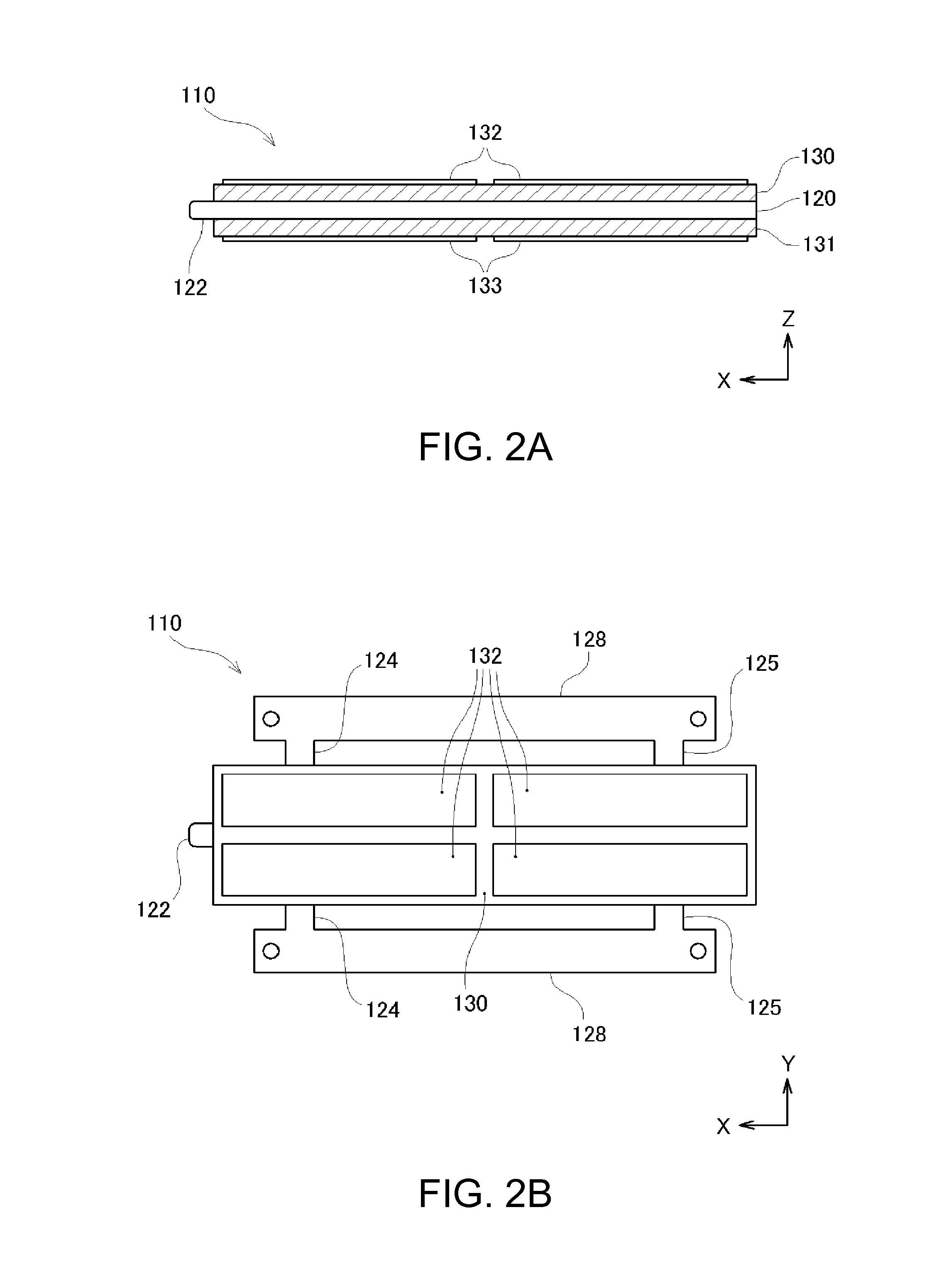

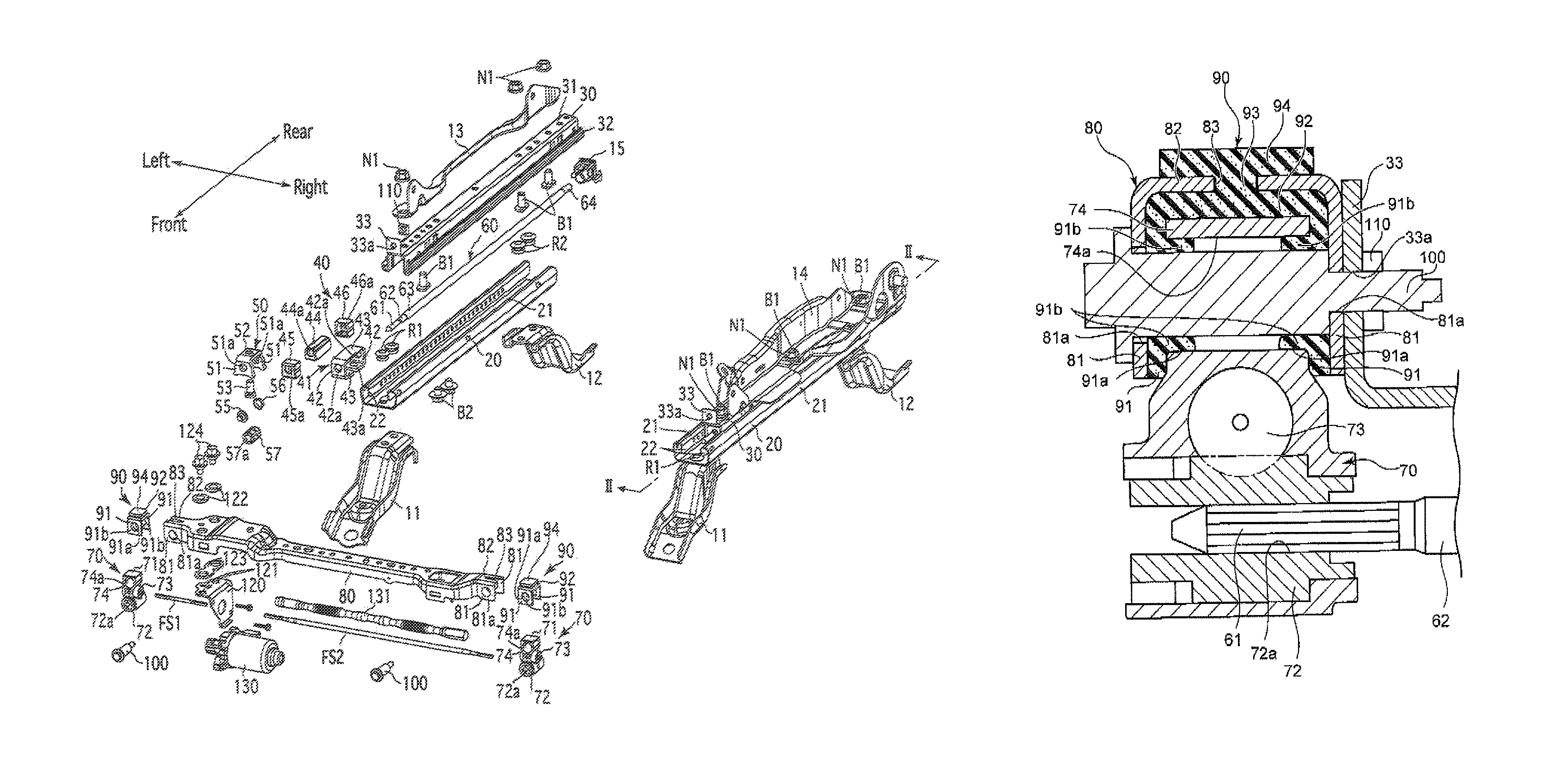

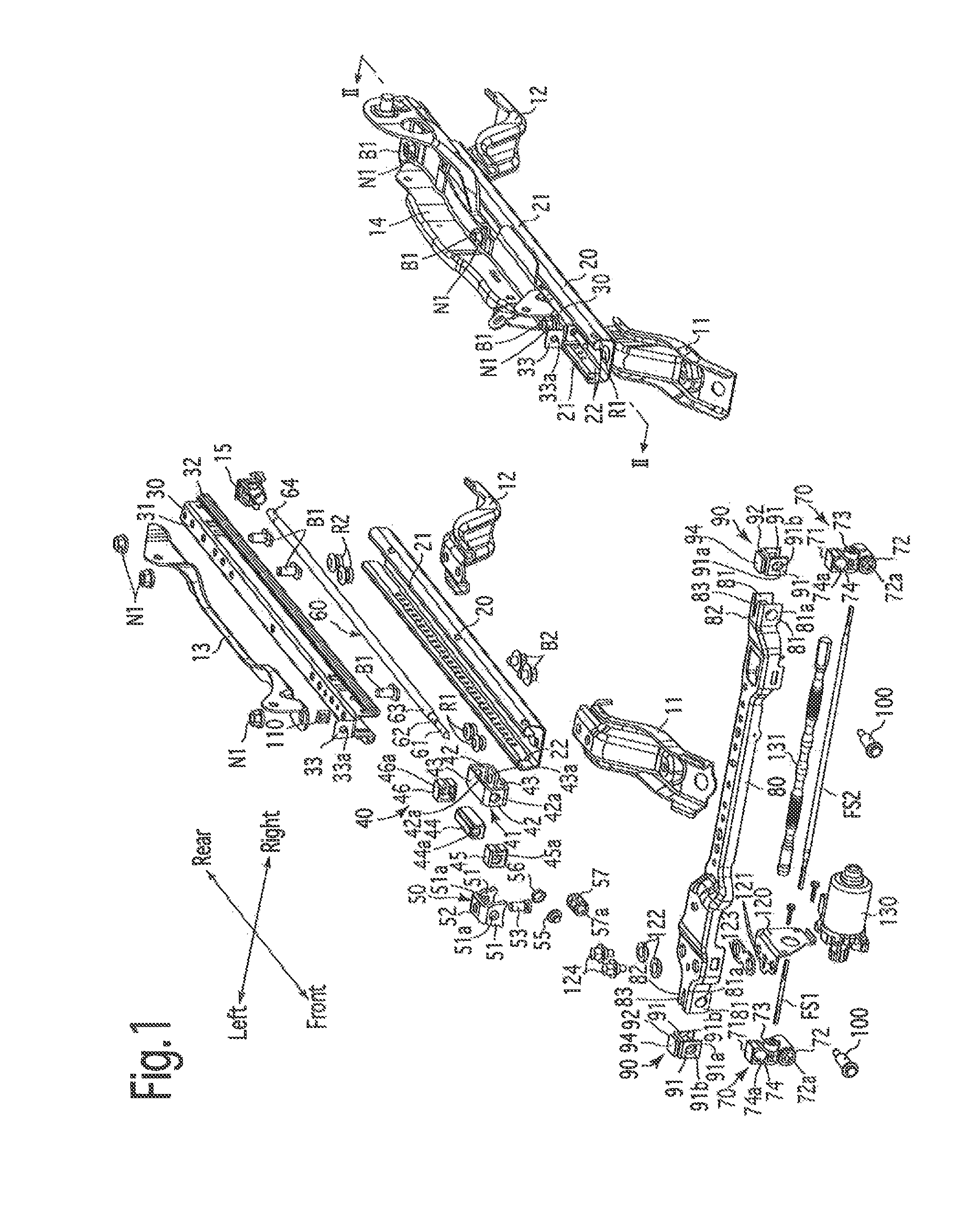

Power slider

ActiveUS8733725B2Avoid spreadingAvoid noiseVehicle seatsNon-rotating vibration suppressionEngineeringScrew thread

Owner:TOYOTA BOSHOKU KK

Devices, Methods and Systems for Acquiring Medical Diagnostic Information and Provision of Telehealth Services

ActiveUS20180360295A1Sufficient transmissionAccurate informationOtoscopesSurgeryThird partyDiagnostic information

The invention relates generally to various systems, tools and methods for acquiring diagnostic information, including medical information, for a user, transmitting the information to a remote location, assessing the information, and transmitting resulting diagnosis and treatment information to the user and / or a third party for subsequent action. The present invention provides consumer and user-friendly telemedicine systems and procedures which enable health services and / or diagnosis to be provided at a distance remotely.

Owner:ZIPLINE HEALTH

Means for removing unwanted ions from an ion transport system and mass spectrometer

InactiveUS20060151690A1Reduce decreaseEasy accessStability-of-path spectrometersSamples introduction/extractionTransport systemIon beam

The present invention relates to inductively coupled plasma mass spectrometry (ICPMS) in which a collision cell is employed to selectively remove unwanted artefact ions from an ion beam by causing them to interact with a reagent gas. The present invention provides a first evacuated chamber (6) at high vacuum located between an expansion chamber (3) and a second evacuated chamber (20) containing the collision cell (24). The first evacuated chamber (6) includes a first ion optical device (17). The collision cell (24) contains a second ion optical device (25). The provision of the first evacuated chamber (6) reduces the gas load on the collision cell (24), by minimising the residual pressure within the collision cell (24) that is attributable to the gas load from the plasma source (1). This serves to minimise the formation, or re-formation, of unwanted artefact ions in the collision cell (24).

Owner:THERMO FISHER SCI BREMEN

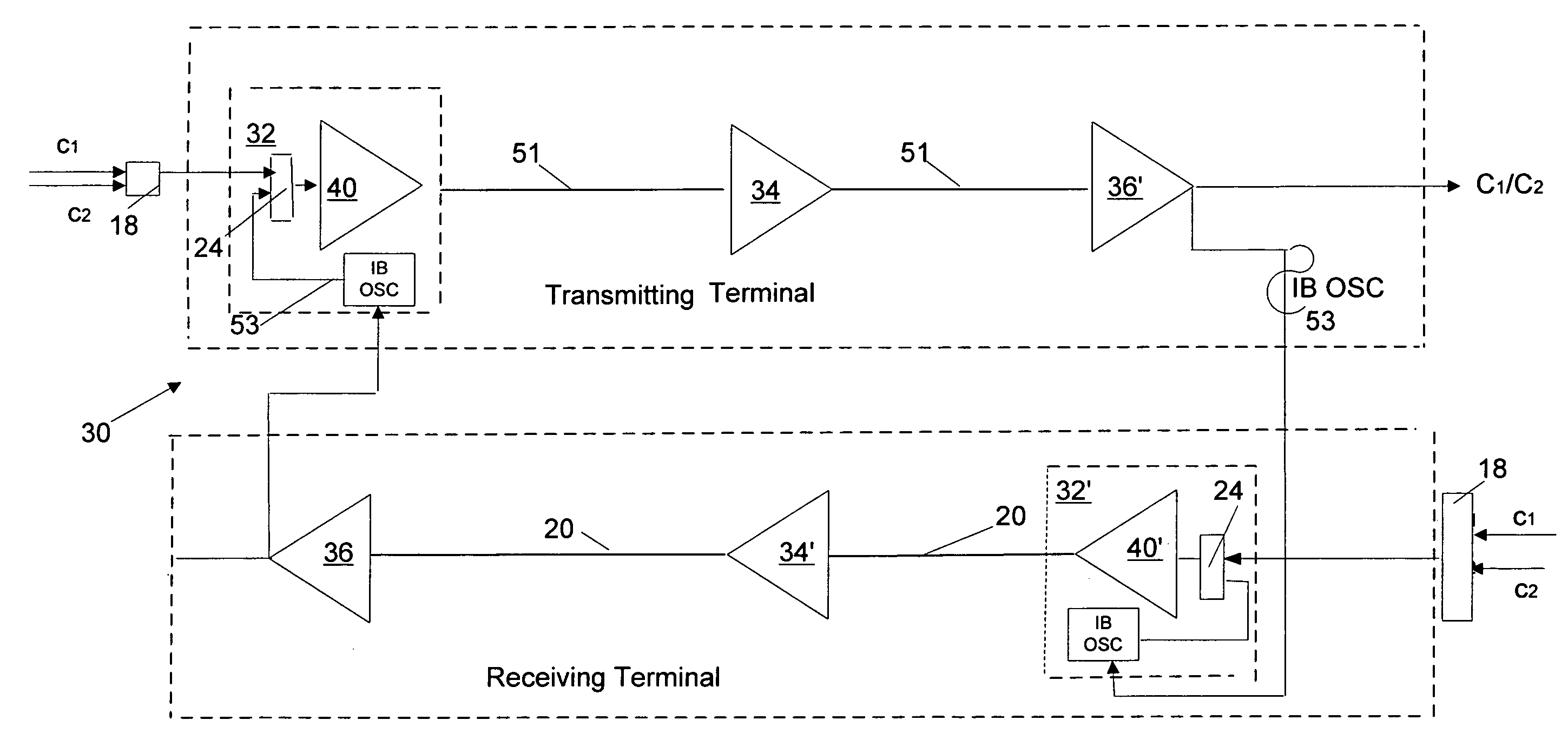

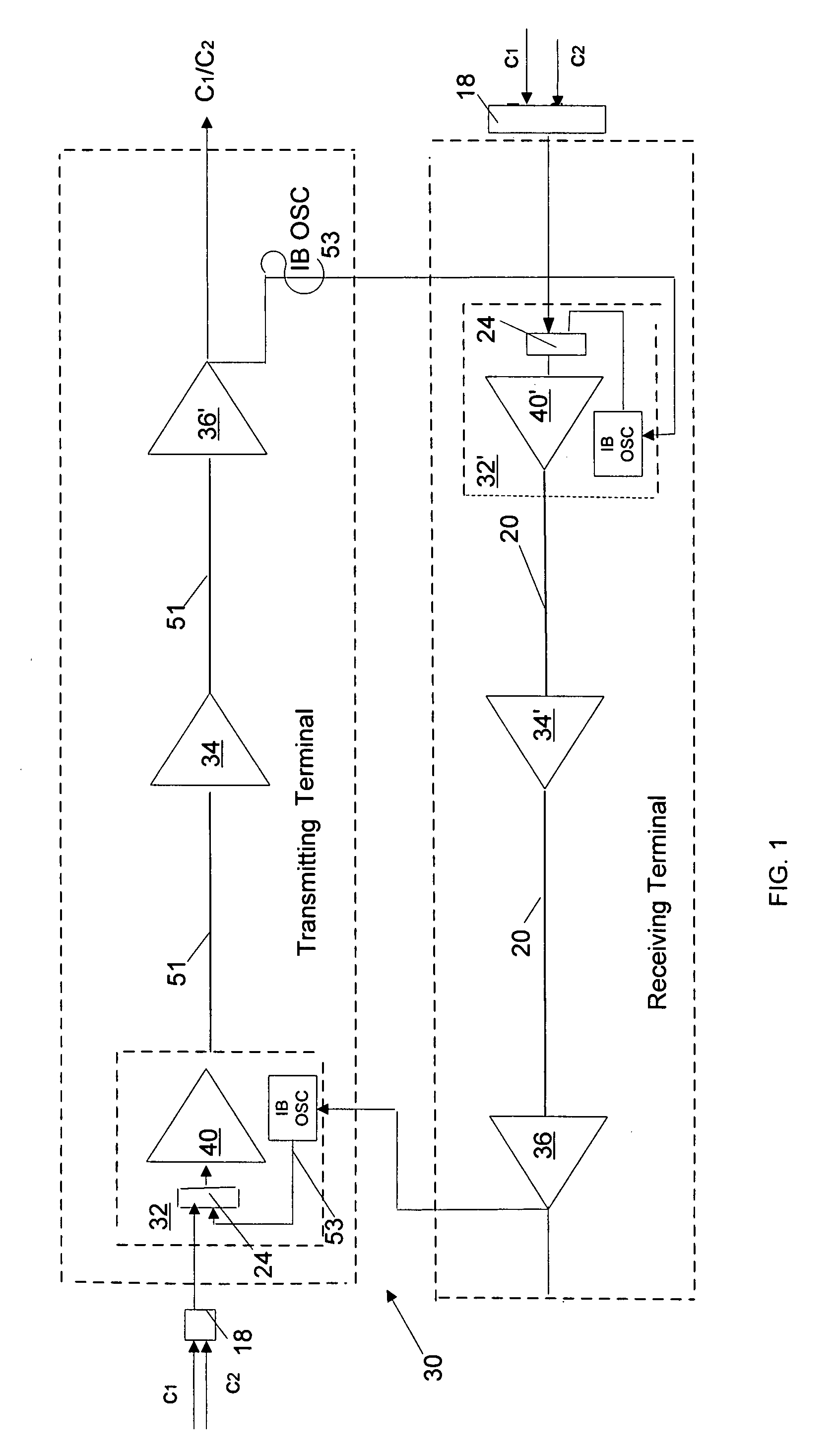

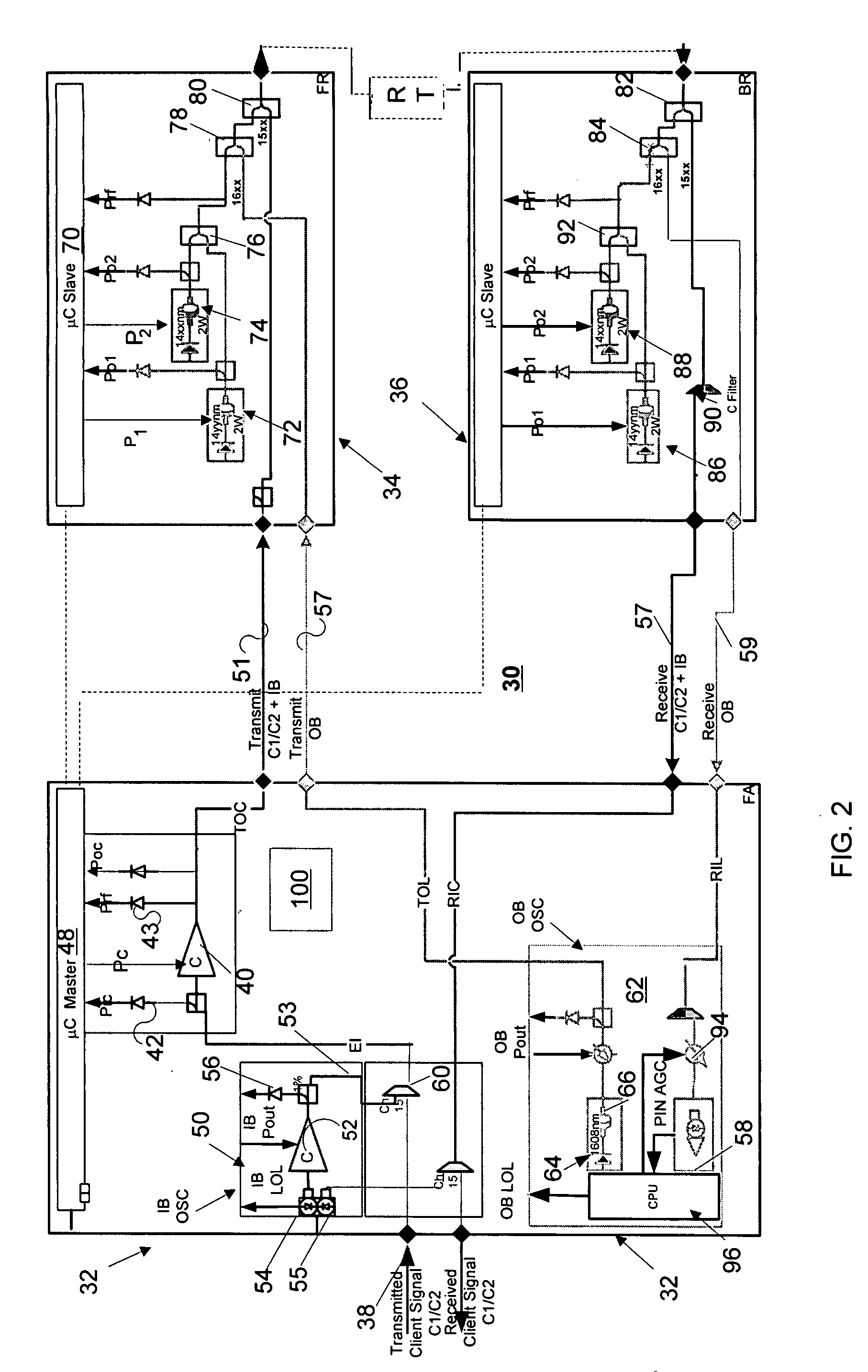

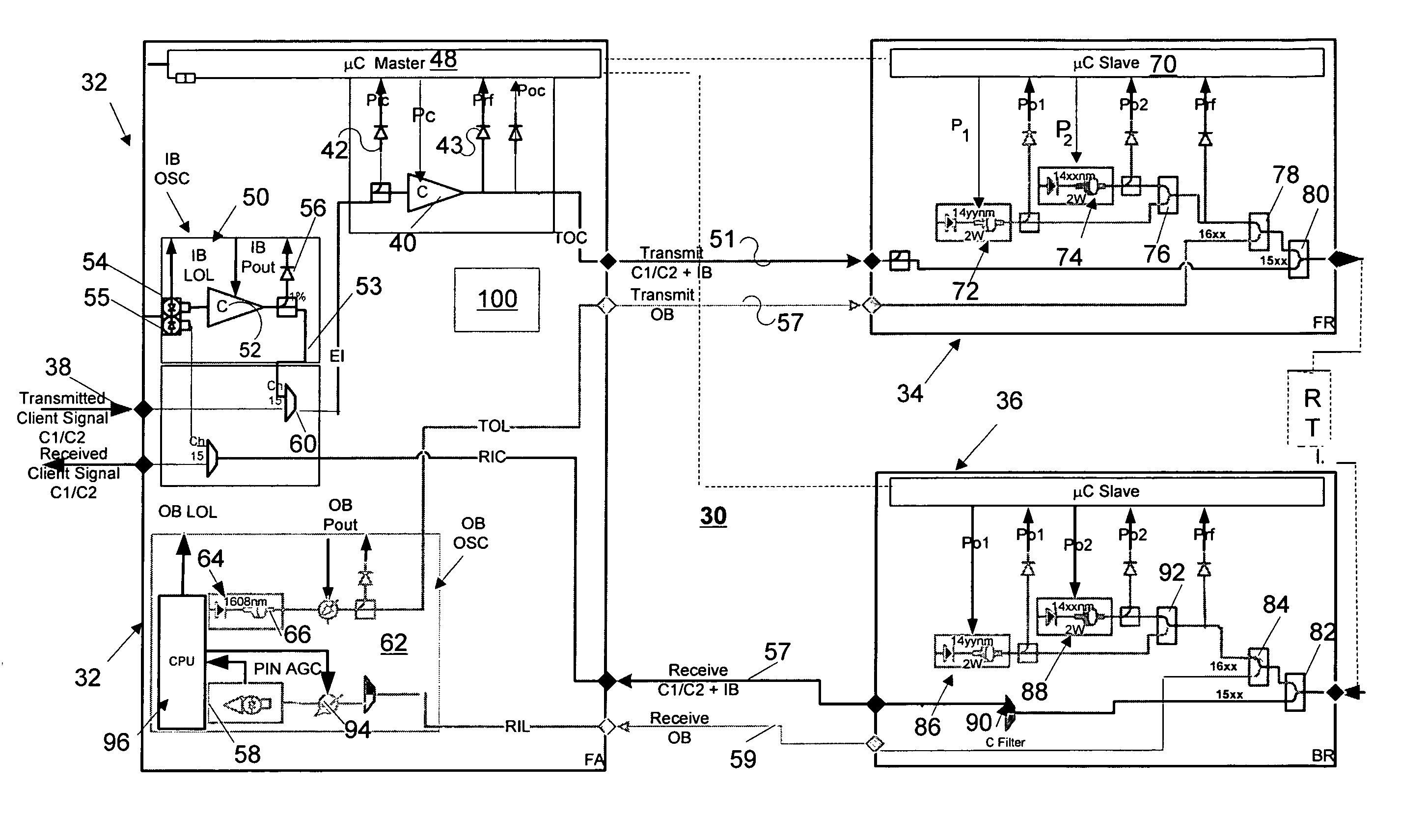

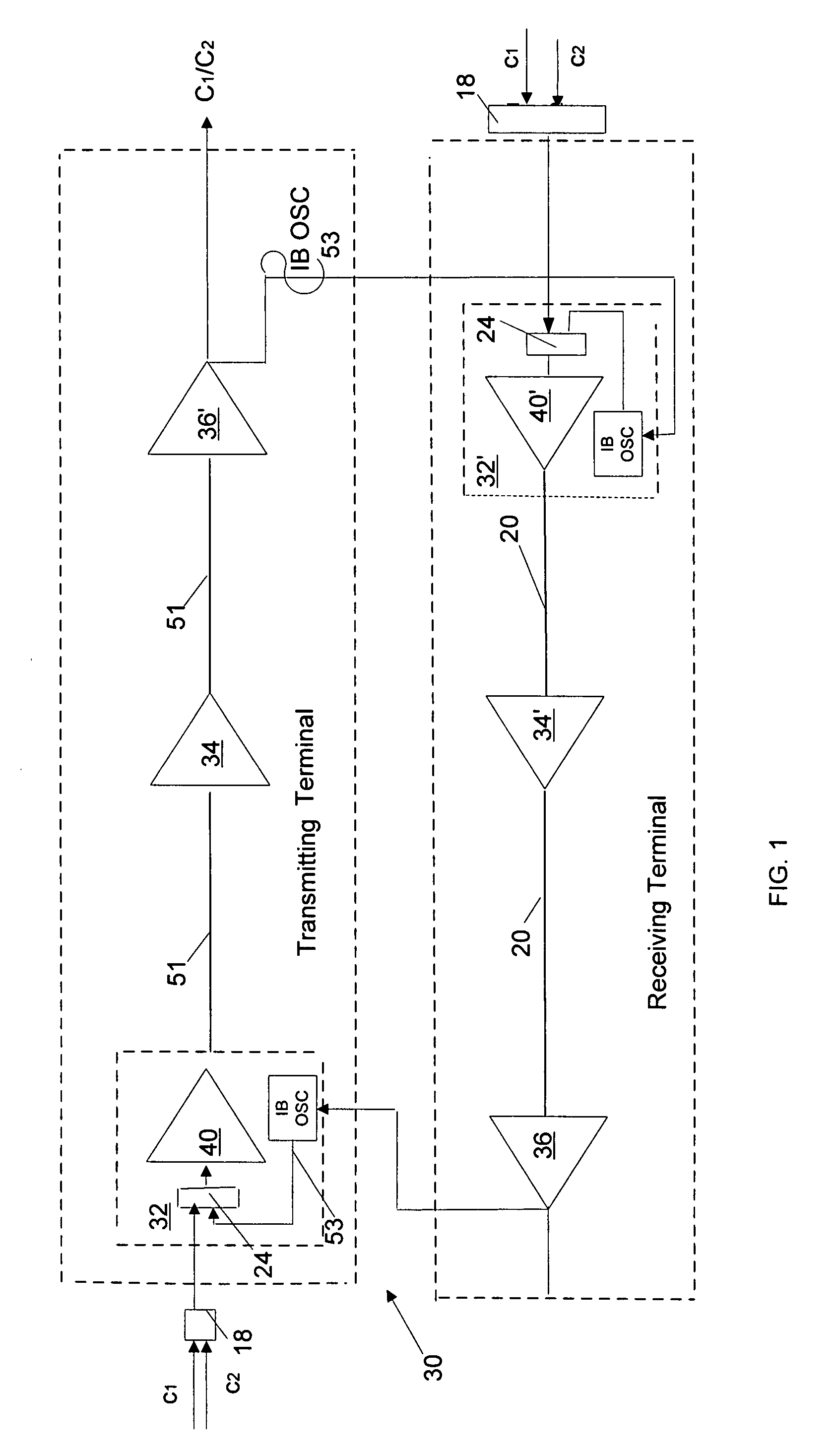

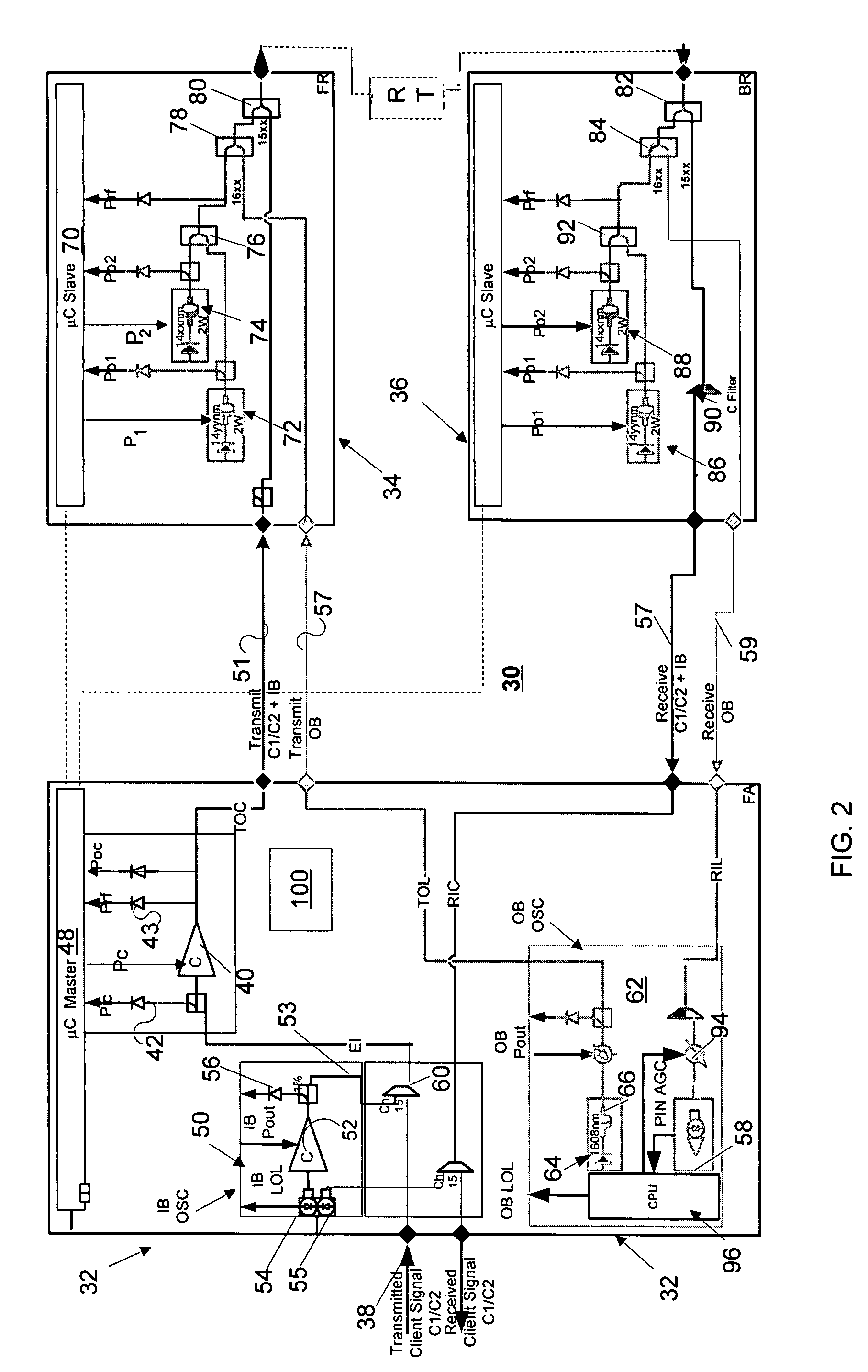

Fiber optic communication system with automatic line shutdown/power reduction

ActiveUS20090142061A1Cost-effective and reliableCost-effectiveWavelength-division multiplex systemsTransmission monitoringFiber-optic communicationPower control

A wavelength division multiplexing (WDM) fiber optic communication system is operative to transmit WDM signals between multiple nodes. Each of the nodes has a booster EDFA, and in-band (IB) and out-of-band (OB) supervisory channels operative to monitor the integrity of a transmission link by generating and detecting respective in-band and out-of-band control signals. The booster EDFA is operative to receive the multiplexed WDM and IB signals and generate an output signal carried by a plurality of fiber-optic cables between the nodes. The booster EDFA is operative to switch from an automatic gain control regime upon detecting of at least one of the IB and OB signals to an automatic power control regime upon loss of both IB and OB signals. The output signal of the EDFA in the AGC regime has a high power sufficient for being transmitted the WDM and IB signals, and has a low power in the APC regime sufficient for transmitting only the IB signal between the nodes.

Owner:IPG PHOTONICS CORP

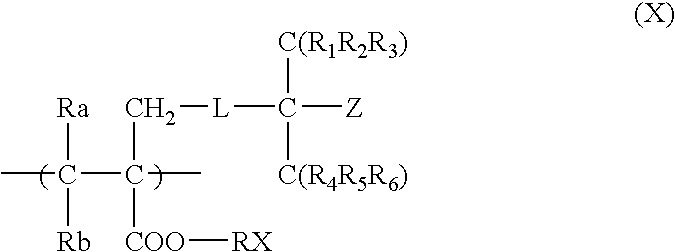

Composition for formation of upper layer film, and method for formation of photoresist pattern

ActiveUS20100021852A1Suppress generation of defect and inferior defectInhibition of defect generationPaper coatingOriginals for photomechanical treatmentSingle bondOrganic chemistry

A composition for formation of upper layer film, which is used for forming an upper layer film on the surface of a photoresist film and which comprisesa resin (A) having a repeating unit represented by the following general formula (1-1) and not having a repeating unit represented by the following general formula (1-2), anda resin (B) having a repeating unit represented by the following general formula (1-2) and not having a repeating unit represented by the following general formula (1-1).[In the general formulas (1-1) and (1-2), R1 is hydrogen or the like; R2 is single bonds or the like; and R3 is a fluorine-substituted, linear or branched alkyl group having 1 to 12 carbon atoms, or the like.] The composition can form an upper layer film giving a sufficiently high receded contact angle.

Owner:JSR CORPORATIOON

Fiber optic communication system with automatic line shutdown/power reduction

InactiveUS7917030B2Improve reliabilityLow costLaser detailsWavelength-division multiplex systemsFiberMultiplexing

A WDM fiber optic communication system is operative to transmit WDM signals between multiple nodes. Each node has a booster EDFA, and in-band and out-of-band supervisory channels monitoring the integrity of a link by generating and detecting respective in-band and out-of-band control signals. The booster EDFA receives the multiplexed WDM and IB signals and generates an output signal carried by fibers between the nodes. The booster EDFA switches from an automatic gain control regime upon detecting of at least one of the IB and OB control signals to an automatic power control regime upon loss of both IB and OB control signals. The output signal of the EDFA in the AGC regime has a high power sufficient for transmitting the WDM and IB signals, and has a low power in the APC regime sufficient for transmitting only the IB control signal.

Owner:IPG PHOTONICS CORP

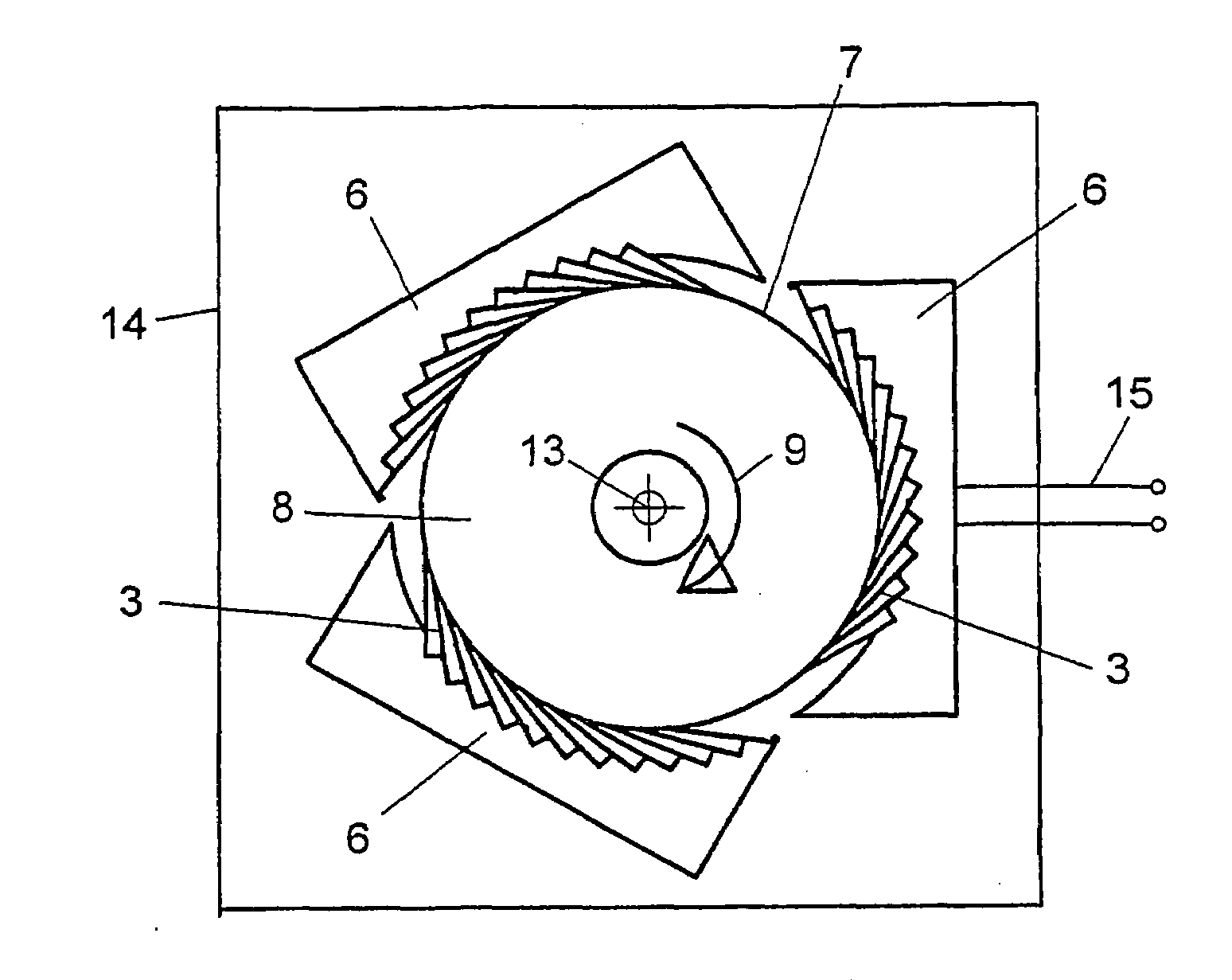

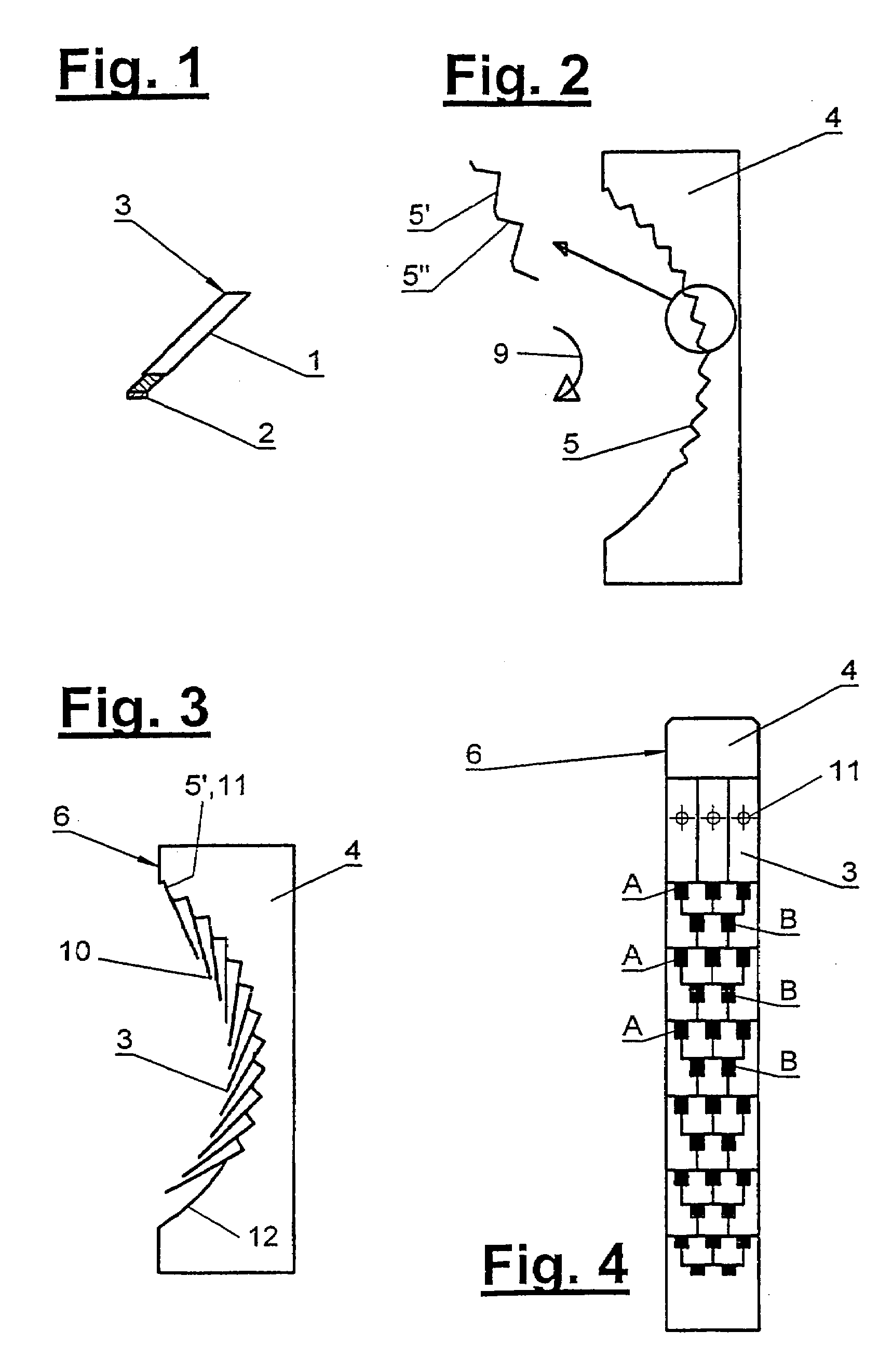

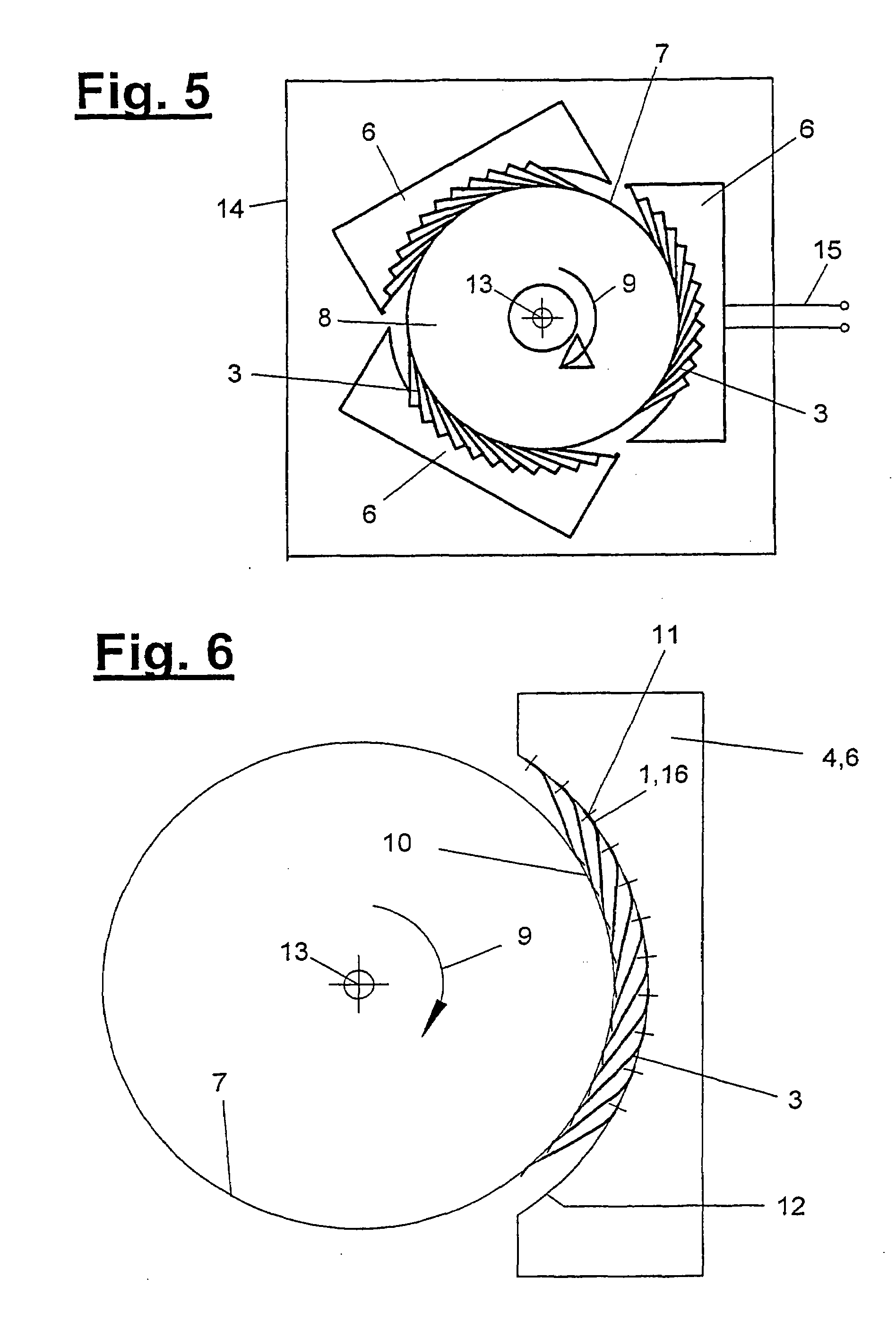

Brush block for transmitting currents

A brush block is provided for transmitting currents to a slip ring using at least one multi-wire slip element with a plurality of parallel connected multi-wire slip elements that are distributed one behind the other in the direction of slip following an imaginary curve. The brush block has a multi-wire slip element support with a curved inner wall on which the multi-wire slip elements are disposed in layers that overlap in scale-like fashion.

Owner:WALTER KRAUS

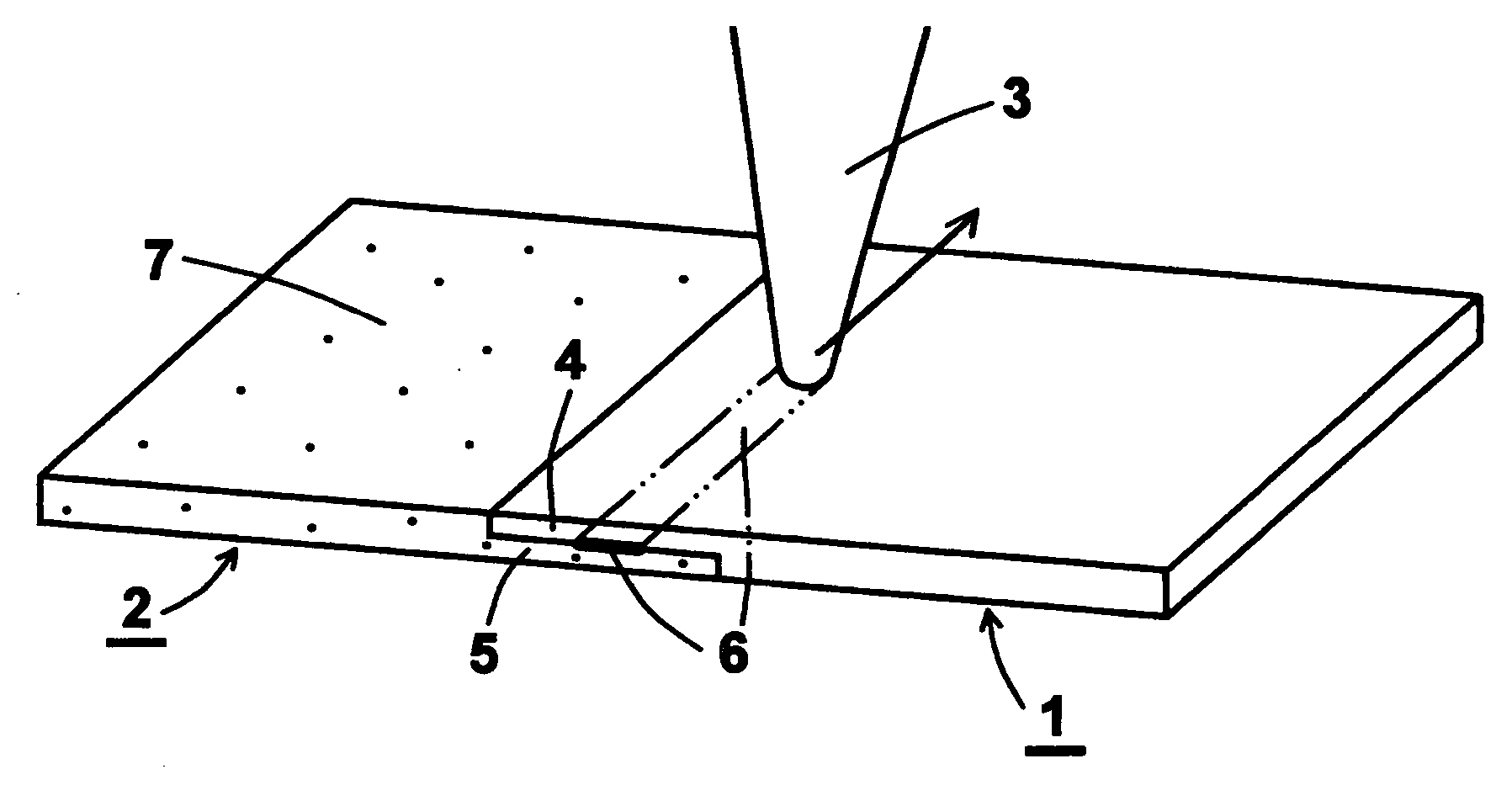

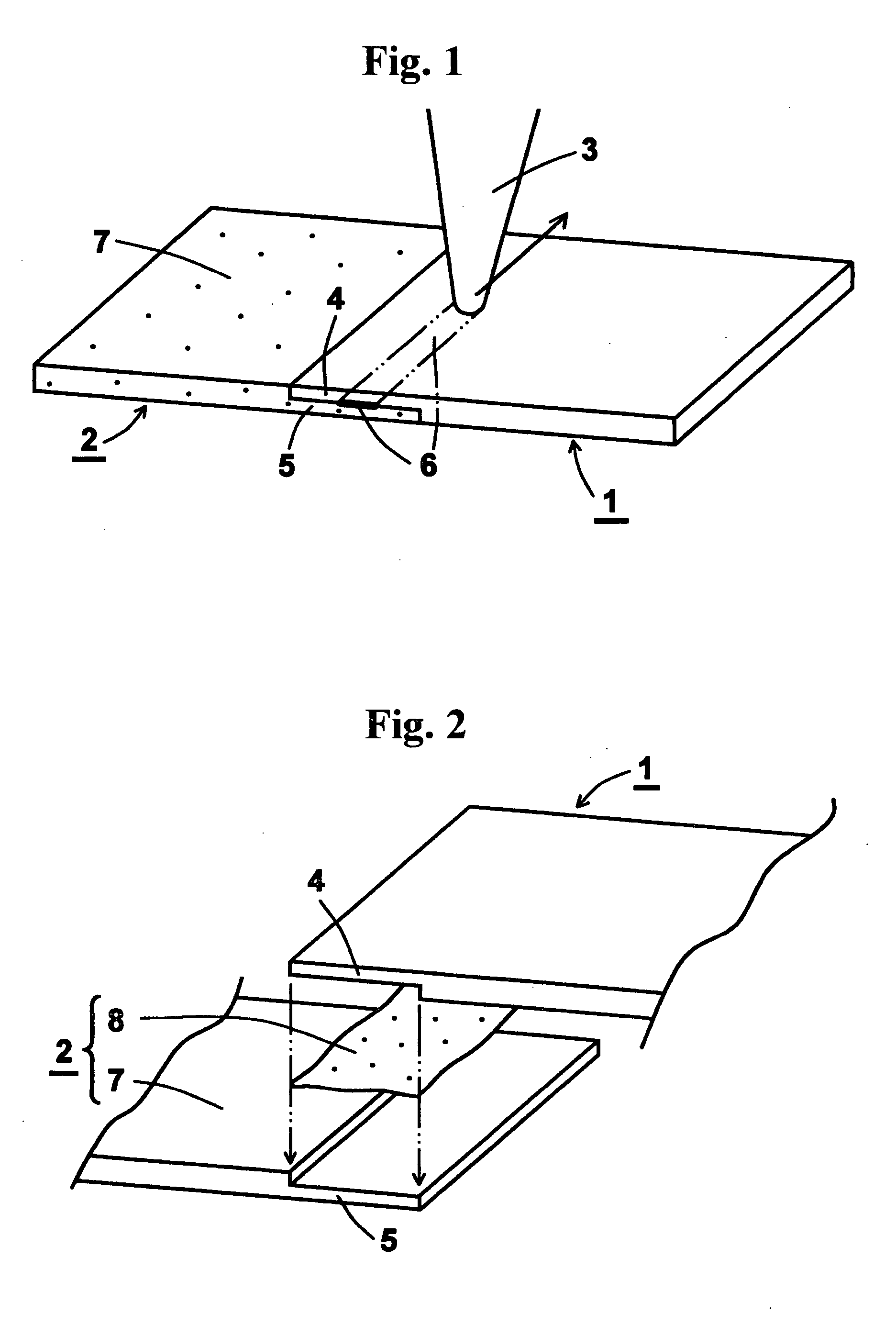

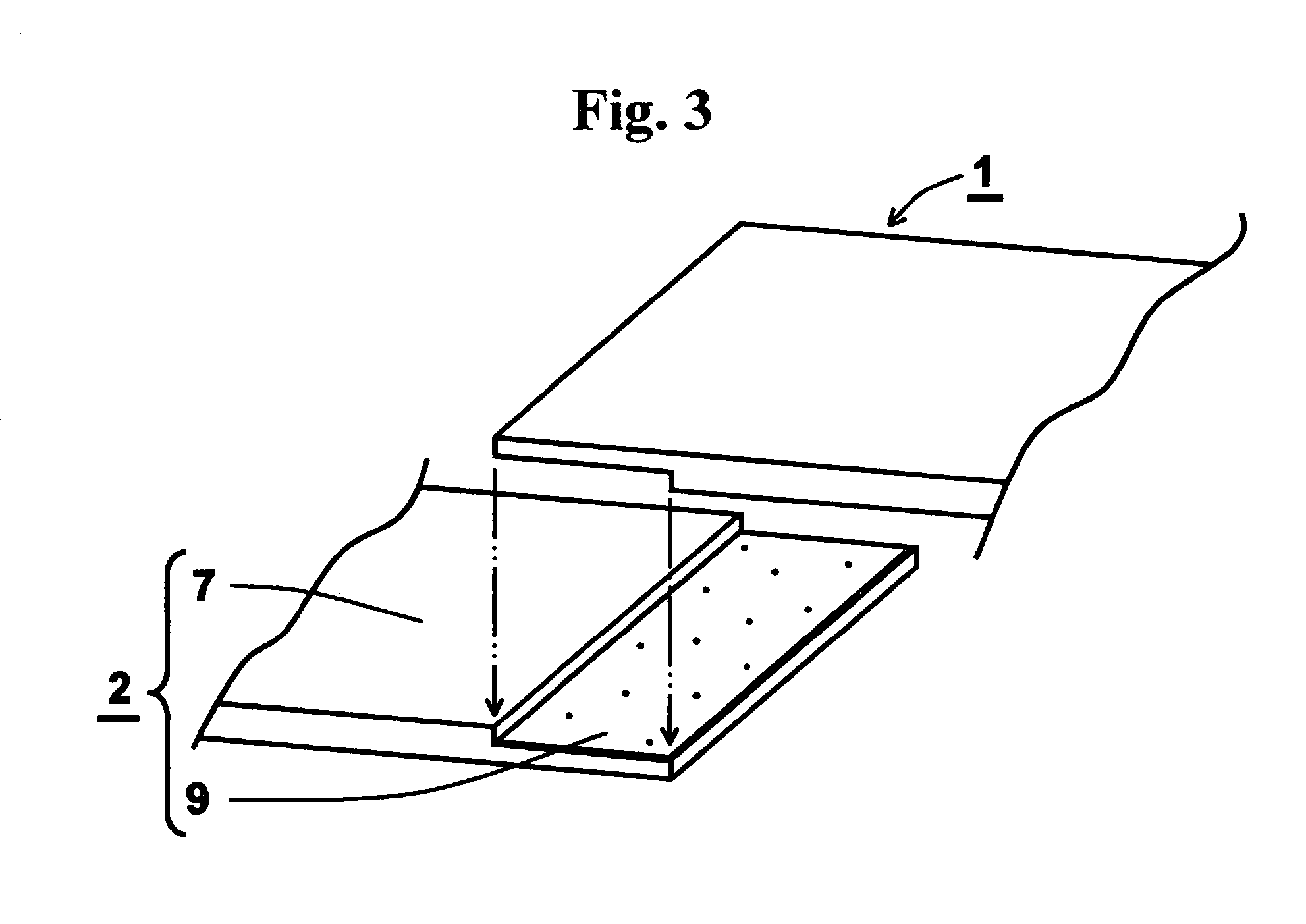

Method for laser welding

InactiveUS20060151099A1Exquisite and complicated shapeImprove air tightnessLamination ancillary operationsLaminationLight beamIrradiation laser

A method for laser welding comprises: forming a laser-transmissible resin workpiece 1 exhibiting whitish hue of white, gray or tint color out of a resin composition which includes 100 parts by weight of a thermoplastic resin and 0.1 to 2 parts by weight of white pigment having 2 to 2.8 of reflectance, piling a resin workpiece 2 being at least partly capable of laser-absorption onto the laser-transmissible resin workpiece 1, and then irradiating a laser beam 3 thereto to weld them thermally.

Owner:ORIENT CHEM INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com