Device and method for monitoring fluid flow in rock sample at high temperature and high pressure

A high-temperature, high-pressure, monitoring device technology, applied in the direction of material resistance, etc., can solve the problems of limited information, data recording and analysis errors, unfavorable operation, etc., and achieve the effect of strong operability, simple structure, and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

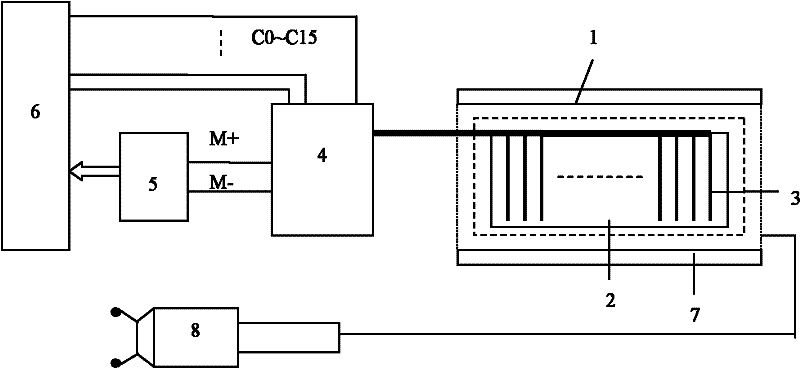

[0040] Below in conjunction with accompanying drawing and example further illustrate the present invention.

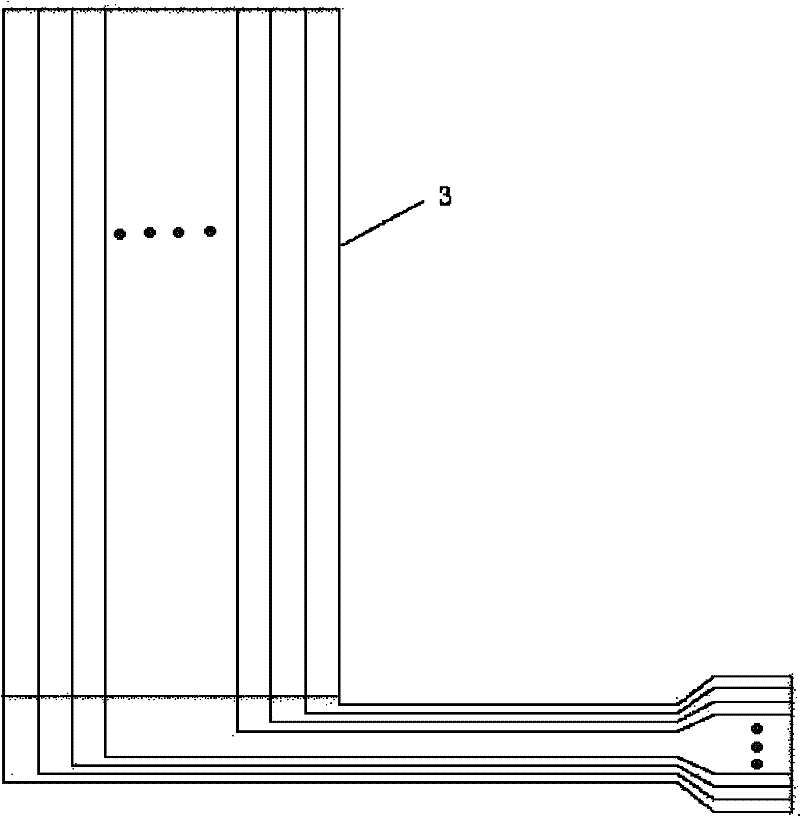

[0041] see figure 2 .

[0042] 16 copper foil electrodes 3 parallel to each other and equally spaced are uniformly arranged on a polyethylene resin sheet. The polyethylene resin sheet is 90 mm long, 50 mm wide, and 0.1 mm thick. The width of each electrode is 0.2 mm, and the distance between electrodes is 3 mm. A plurality of electrodes are used to divide the rock sample into a plurality of small rock pillars of equal length along the axial direction, that is, a plurality of measurement areas.

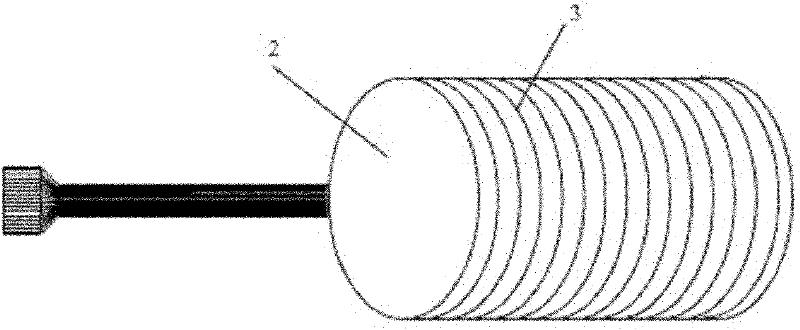

[0043] see image 3 .

[0044] The rock sample 2 is wrapped with a polyethylene resin sheet, and the side covered with electrodes 3 is in contact with the rock sample surface, and each electrode is bent into a ring connected end to end, and the plane of the ring is perpendicular to the axis of the rock sample. Each microelectrode ring leads a wire to connect with the exter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com