A compressible fluid pumping system

A technology of compressing fluid and pressurizing fluid, applied in the direction of pumps, pump components, pump devices, etc., can solve problems such as poor metering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

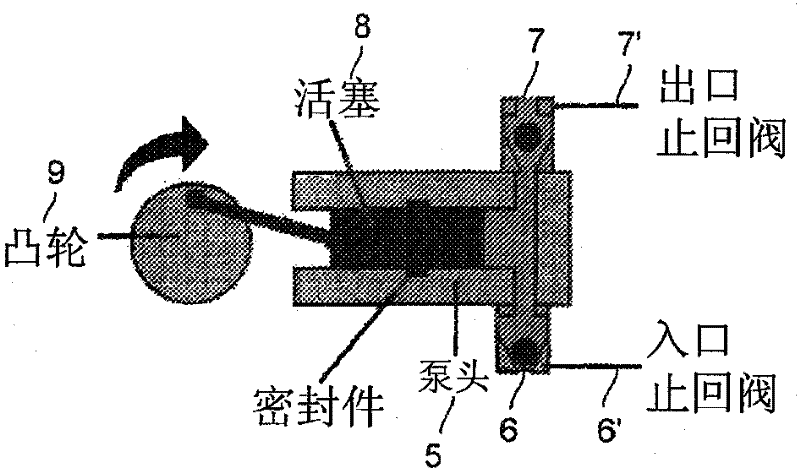

[0058] refer to Figure 7 , shows a schematic diagram of a preferred embodiment of the invention. Booster pump 70 receives compressible fluid from reservoir 72 . An optional prechiller 74 cools the compressible fluid input stream and also the pump head of the booster pump 70 . Booster pump 70 delivers flow to an output flow path that includes optional pulsation dampener 76 , booster pressure sensor 78 , and thermal conditioning device 80 . Metering pump 82 receives the output flow of booster pump 70 and delivers flow through optional temperature sensor 84 and process pressure sensor 86 to process flow stream 88 . Controller 90 receives sensor signals from pressure sensor 78 , pressure sensor 86 , and optional temperature sensor 84 . Controller 90 further controls optional thermal zones of device 74 and device 80 and controls the pumping speed of booster pump 70 . Optionally, controller 90 also controls the metering speed of metering pump 82, although this is not required f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com