Experimental device for high temperature and high pressure anti-corrosion reaction

An experimental device, high temperature and high pressure technology, used in measuring devices, sampling devices, instruments, etc., can solve the problems of difficult temperature and pressure control, inability to take online sampling, and bulky kettle body, and achieve good thermal insulation effect, strong corrosion resistance, and appearance. nice neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

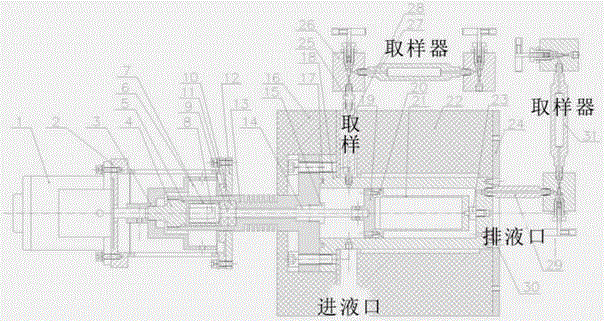

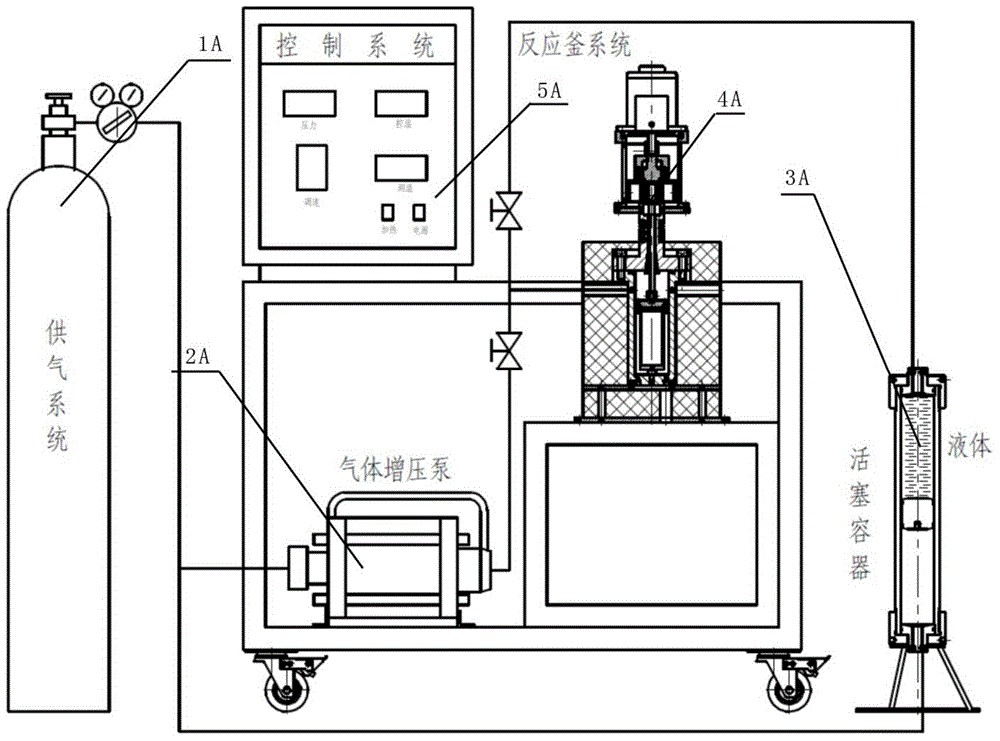

[0024] Example: such as Figure 1 ~ Figure 3 As shown, the present invention includes gas supply system, piston container 3A, reactor system 4A and control system 5A;

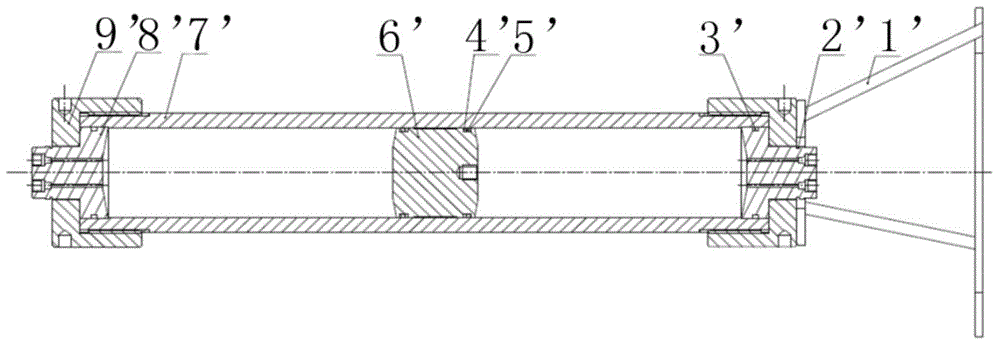

[0025] The gas supply system includes a high-pressure gas cylinder 1A and a gas booster pump 2A, through which the injected reaction liquid is used to simulate the formation water used for organic acid generation or the organic acid used for simulated dissolution is transported from the piston container 3A to the reactor system 4A, and the pump The flow range is 0.01-10mL / min, the maximum output pressure is 50MPa, and the pump head is made of Hastelloy material, so it can withstand certain acid and alkali liquids. The piston container 3A is installed on the base 1', and the piston container 3A includes a piston 6' and a cylinder body 7'. Plugs 8' are installed at both ends of the cylinder body 7', and sealing rings 3' are installed on the plugs 8'. The end is provided with a pressure cap 9'; the cylinder cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com