Thin film crystal silicon perovskite heterojunction solar cell manufacturing method

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low yield, many process steps, and small size of thin-film crystalline silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

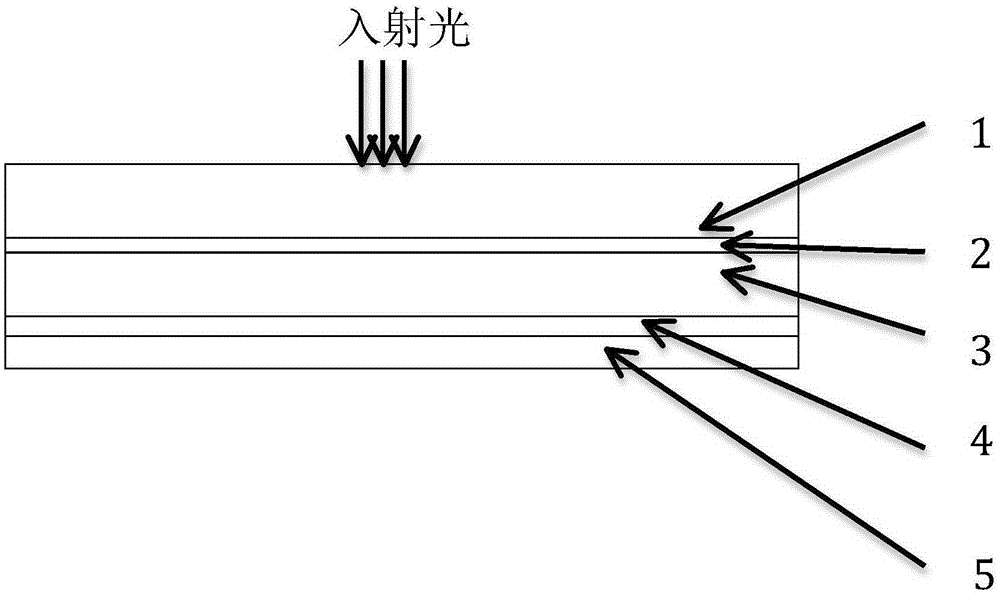

[0056] A method for preparing a thin-film crystalline silicon perovskite heterojunction solar cell in this embodiment is a method for preparing a thin-film crystalline silicon perovskite heterojunction solar cell based on an excimer laser crystallization method, and the steps are as follows:

[0057] The first step is to prepare a P-type thin film crystalline silicon layer on the transparent conductive substrate of the AZO transparent oxide conductive layer based on glass:

[0058] (1.1) Preparation of P-type α-Si:H amorphous silicon thin film: Place the transparent conductive substrate of the AZO transparent oxide conductive layer based on glass on the sample stage of the PECVD equipment, and through the PECVD method, the reaction pressure is 5Pa. Bottom temperature 50°C, SiH 4 The gas flow rate is 0.lsccm, H 2 Gas flow rate is 1sccm, PH 3 Under the condition that the gas flow rate is 0.000lsccm, a 20nm thick P-type α-Si:H amorphous silicon film is grown on a transparent co...

Embodiment 2

[0078] A method for preparing a thin-film crystalline silicon perovskite heterojunction solar cell is a method for preparing a thin-film crystalline silicon perovskite heterojunction solar cell based on an excimer laser crystallization method. The steps are as follows:

[0079] The first step is to prepare a P-type thin film crystalline silicon layer on the transparent conductive substrate of the ITO transparent oxide conductive layer based on glass:

[0080] (1.1) Preparation of P-type α-Si:H amorphous silicon thin film: the transparent conductive substrate of the ITO transparent oxide conductive layer based on glass is placed on the sample stage of the PECVD equipment, and the reaction pressure is 27Pa under the reaction pressure of 27Pa. Bottom temperature 200°C, SiH 4 The gas flow rate is 5 sccm, H 2 Gas flow rate is 50sccm, PH 3 Under the condition that the gas flow rate is 0.5 sccm, a 1000nm thick P-type α-Si: H amorphous silicon film is grown on the transparent conduc...

Embodiment 3

[0100] A method for preparing a thin-film crystalline silicon perovskite heterojunction solar cell is a method for preparing a thin-film crystalline silicon perovskite heterojunction solar cell based on an excimer laser crystallization method. The steps are as follows:

[0101] The first step is to prepare a P-type thin film crystalline silicon layer on the transparent conductive substrate of the FTO transparent oxide conductive layer based on glass:

[0102] (1.1) Preparation of P-type α-Si:H amorphous silicon thin film: the transparent conductive substrate of the FTO transparent oxide conductive layer based on glass is placed on the sample stage of PECVD equipment, and the reaction pressure is 50Pa under the reaction pressure of 50Pa. Bottom temperature 350℃, SiH 4 Gas flow rate is 10sccm, H 2 Gas flow is l00sccm, PH 3 Under the condition that the gas flow rate is 1 sccm, a 2000nm thick P-type α-Si:H amorphous silicon film is grown on the transparent conductive substrate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com