Low-temperature continuous production process for lithium iron phosphate and dedicated device therefor

A lithium iron phosphate and production process technology, applied in the field of preparation of in, ion-doped lithium iron phosphate materials, can solve the problem of poor high current discharge capability of synthetic materials, limiting large-scale industrialization of lithium iron phosphate, and powder preparation process time. Long and other problems, to achieve the effect of excellent electrochemical performance, wide application range of raw materials, and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

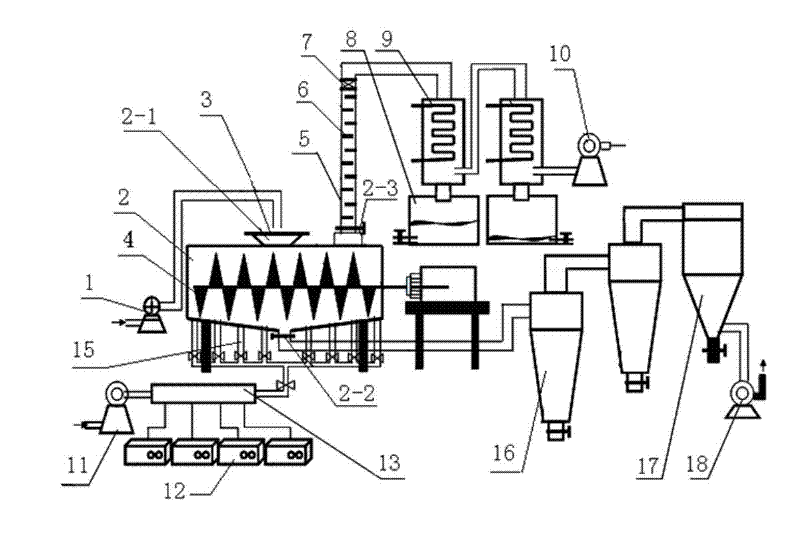

[0018] Embodiment 1: the structure of special equipment.

[0019] The horizontal stirring dryer 2 of this embodiment is equipped with a heat transfer oil circulating agitator 4 . Make the material evenly heated. The feed pump 1 communicates with the feed inlet 2-1 of the horizontal stirring dryer 2, and the upper end of the feed inlet has a sealing cover 3, and the gas outlet valve 2-3 on the upper side of the horizontal stirring dryer is connected to the slow flow of the solvent recovery system. One end of the tube 5 is connected, and ten axially extending spiral baffles are arranged in the slow-flow tube as the turbulence device 6, and its function is to reduce the air velocity of solvent volatilization. device7. The filter device consists of two layers of screen mesh and cotton wool to form a filter cloth. The main function is to prevent the passage of fine material particles.

[0020] The other end of the slow flow tube communicates with the condenser 9, and the conden...

Embodiment 2

[0024] (1) Weigh 8.64 kg of ferrous oxalate, 7.68 kg of iron oxide, 10.40 kg of lithium dihydrogen phosphate, 0.820 kg of glucose, 17.240 kg of oxalic acid, 0.226 kg of yttrium oxide, and 0.266 kg of niobium oxide. The solvent methanol was added to the stirrer with a circulating reflux device, stirred at room temperature for 0.5h, and the stirring speed was 400r / min, and a light yellow lithium iron phosphate precursor slurry was obtained; the obtained slurry was added to a dryer. Fluidized drying, compressed air is blown into the drying process with a flow rate of 80m 3 / h, the drying temperature is 80°C, and the drying time is 2h. After drying, a lithium iron phosphate precursor powder containing a composite carbon source and a composite metal compound is obtained; the volatilized solvent is recycled by condensation. The obtained lithium iron phosphate precursor powder is ultrafinely pulverized to obtain a fine powder with a particle size of 200 mesh, and then mechanically c...

Embodiment 3

[0028] (2) Weigh 8.82 kg of ferrous oxalate, 7.84 kg of iron oxide, 10.40 kg of lithium dihydrogen phosphate, 0.480 kg of chitosan, 0.420 kg of fruit acid, 17.240 kg of oxalic acid, 0.062 kg of magnesium fluoride, and 0.151 kg of tin oxide , first mixed, and then added together with the solvent methanol into a stirrer with a circulating reflux device, stirred at room temperature for 0.2h, and the stirring speed was 200r / min, to obtain a light yellow lithium iron phosphate precursor slurry; the obtained The slurry is added to the dryer for fluidized drying, and the compressed air is blown into the drying process with a flow rate of 40m 3 / h, the drying temperature is 70°C, and the drying time is 4h. After drying, a lithium iron phosphate precursor powder containing a composite carbon source and a composite metal compound is obtained; the volatilized solvent is recycled by condensation. The obtained lithium iron phosphate precursor powder is ultrafinely pulverized to obtain a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com