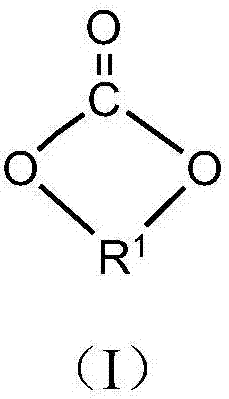

Method for preparing isocyanate thermoplastic polyurea by using one-pot method

A non-isocyanate, thermoplastic polyurea technology, applied in the field of polyurethane, can solve problems such as cumbersome process, achieve the effects of good mechanical properties, convenient and efficient preparation process, and convenient continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

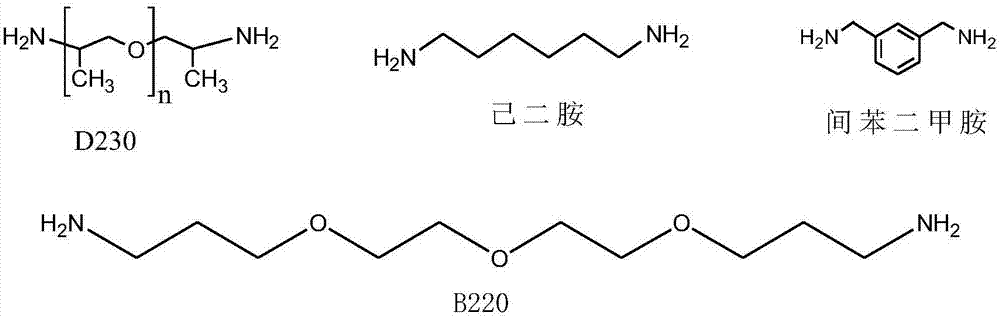

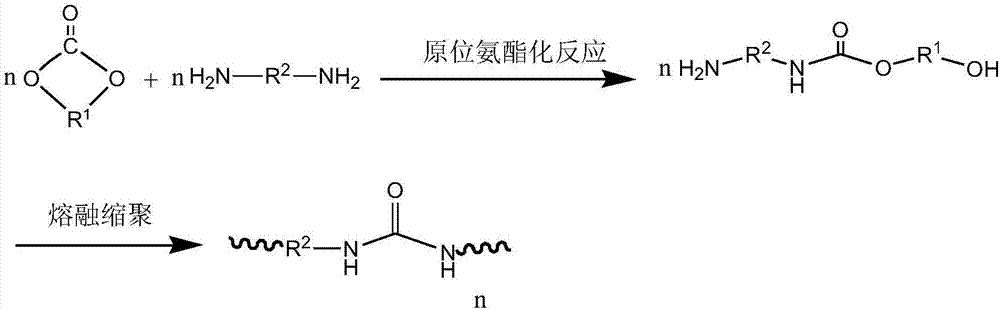

Method used

Image

Examples

Embodiment 1

[0024] Weigh 23 parts of D230 and 8.8 parts of ethylene carbonate according to parts by weight, react at 100°C under normal pressure for 6 hours under the protection of nitrogen, then heat at normal pressure to 170°C, gradually depressurize the water pump to 30mmHg and react for 0.5 hours, and then use the oil pump to Reaction under reduced pressure at 2-3 mmHg until the viscosity of the system no longer changes, and a light yellow transparent thermoplastic polyurea with Mn=10417, Mw=14261, tensile strength of 1.79 MPa and elongation at break of 1330.12% is obtained.

Embodiment 2

[0026] Weigh 13.8 parts of D230, 4.65 parts of hexamethylenediamine, and 8.8 parts of ethylene carbonate in parts by weight, and react at 100°C under normal pressure for 6 hours under the protection of nitrogen, then heat to 170°C under normal pressure, and gradually reduce the pressure to 30mmHg for reaction After 0.5 hours, use an oil pump to react under reduced pressure at 2 to 3 mmHg until the viscosity of the system does not change any more, and obtain a light yellow transparent thermoplastic polyurea, [η] = 0.83dL / g, tensile strength 16.17MPa, elongation at break The rate is 314.74%.

Embodiment 3

[0028] Weigh 16.1 parts of D230, 4.09 parts of m-xylylenediamine, and 8.8 parts of ethylene carbonate in parts by weight, react at 100°C under normal pressure for 6 hours under the protection of nitrogen, then heat to 170°C under normal pressure, and gradually depressurize to React at 30mmHg for 0.5 hours, and then use an oil pump to react under reduced pressure at 2 to 3mmHg until the viscosity of the system no longer changes, and obtain a light yellow opaque thermoplastic polyurea with Mn=11244, Mw=19754, tensile strength 21.86MPa, fracture Elongation 284.13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com