A kind of preparation method of spherical nickel-manganese binary material

A binary material, nickel-manganese technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of inability to meet the requirements at the same time, high nickel price, inability to meet the price, etc., to achieve easy control of reaction, long cycle life, high voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

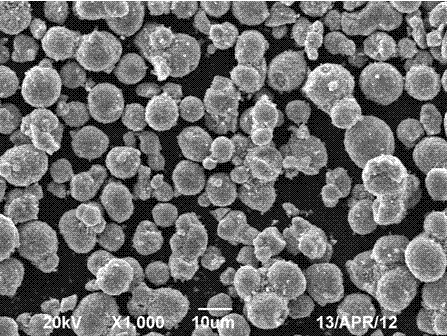

Image

Examples

Embodiment 1

[0022] ①. Use pure water as the bottom liquid, set the temperature at 60°C, control the stirring speed at 145-155r / min, add 10% ammonia water (volume percentage, the same below) and a concentration of 20% (weight percentage , the same below) with sodium hydroxide solution to adjust the alkalinity of the bottom liquid to 30g / l, and the pH value to be 10.5-11.0.

[0023] ②. Dissolve nickel sulfate and manganese chloride at a molar ratio of 4:1 to form a mixed aqueous solution. After mixing evenly, the total metal ion concentration is controlled to 1mol / l.

[0024] Then pump 20% sodium hydroxide solution, 10% ammonia water and mixed aqueous solution into the bottom liquid continuously and concurrently, and a precipitation reaction occurs at 60°C. The stirring speed is controlled at 145-155r / min, and the alkali The density is 28-32g / l, the pH value is 10.5-11.0, and the solid content of the slurry is 140-160g / l.

[0025] The reactants produce crystal nuclei, and the crystal nucle...

Embodiment 2

[0029] ①. Use pure water as the bottom liquid, set the temperature at 70°C, control the stirring speed at 195-205r / min, add 15% ammonium salt solution (weight percentage, the same below) and 25% hydrogen hydroxide The sodium solution adjusts the alkalinity of the bottom solution to 35g / l, and the pH value is 11.0-11.5.

[0030] ②. Dissolve nickel nitrate and manganese sulfate at a molar ratio of 7:3 to form a mixed aqueous solution. After mixing evenly, the total metal ion concentration is controlled to 1.5mol / l.

[0031] Then pump 25% sodium hydroxide solution, 15% ammonium salt solution and mixed aqueous solution into the bottom liquid continuously and concurrently, and a precipitation reaction occurs at 70°C. Control the stirring speed at 195-205r / min, and control the reaction system The alkalinity is 33-37g / l, the pH value is 11.0-11.5, and the solid content of slurry is 190-210g / l.

[0032] The reactants produce crystal nuclei, and the crystal nuclei grow into spherical ...

Embodiment 3

[0035] ①. Use pure water as the bottom liquid, set the temperature at 75°C, control the stirring speed at 235-245r / min, add 15% ammonium salt solution and 25% sodium hydroxide solution to adjust the alkalinity of the bottom liquid to 40g / l, the pH value is 11.2-11.7.

[0036] ②. Dissolve nickel nitrate and manganese chloride in a molar ratio of 3:2 to form a mixed aqueous solution. After mixing evenly, the total metal ion concentration is controlled to 1.5mol / l.

[0037] Then pump 25% sodium hydroxide solution, 15% ammonium salt solution and mixed aqueous solution into the bottom liquid continuously and concurrently, and a precipitation reaction occurs at 75°C. The stirring speed is controlled at 235-245r / min to control the reaction system. The alkalinity is 38-42g / l, the pH value is 11.2-11.7, and the solid content of slurry is 235-245g / l.

[0038] The reactants produce crystal nuclei, and the crystal nuclei grow into spherical particles. The reaction feed liquid continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com