High-voltage soft polyolefin wire material for new energy automobile and preparation method thereof

A soft polyolefin and new energy vehicle technology, applied in the field of wire materials, can solve the problems of unsolved higher temperature resistance level, unstable high temperature aging, poor mechanical and physical properties, etc., and achieves low preparation cost, thermal stability and Good anti-aging effect and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The polyolefin wire material is prepared by irradiation crosslinking; the olefin copolymer is 1,1,1-trifluoro-2-(trifluoromethyl)-4-pentan-2-ol, 1, 3-adamantanediol monoacrylate and acrylonitrile are prepared by free radical copolymerization; the preparation method of the olefin copolymer comprises the following steps: 1,1,1-trifluoro-2-(trifluoromethyl )-4-pentan-2-ol, 1,3-adamantane diol monoacrylate, acrylonitrile, and initiator are added to the high boiling point solvent, and the reaction is stirred at 70-80°C under nitrogen or inert gas atmosphere 3- After 5 hours, it was precipitated in water, and dried to constant weight in a vacuum oven at 80-90°C to obtain an olefin copolymer.

[0031] Further, the 1,1,1-trifluoro-2-(trifluoromethyl)-4-pentan-2-ol, 1,3-adamantanediol monoacrylate, acrylonitrile, initiator, high The mass ratio of the boiling point solvent is 1:1:(2-3):(0.03-0.05):(15-24).

[0032] Further, the initiator is at least one of azobisisobutyronitril...

Embodiment 1

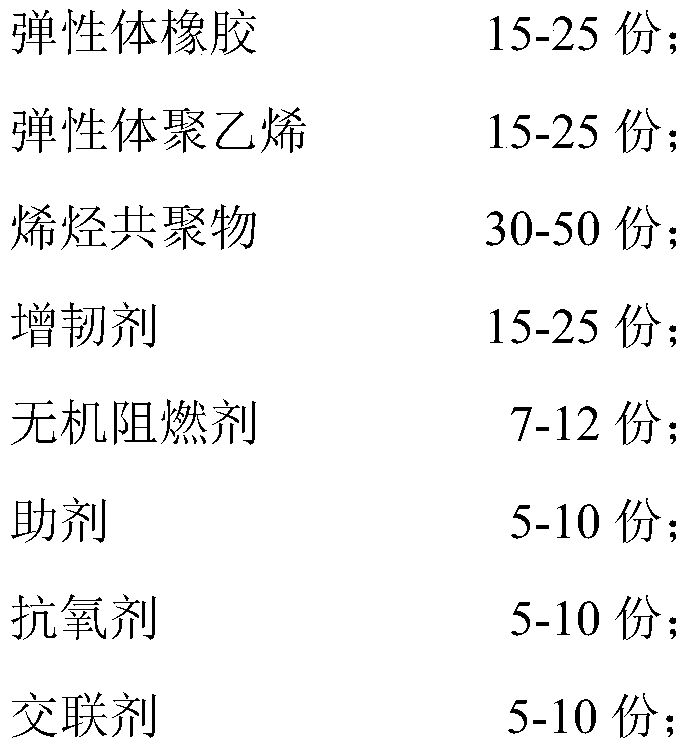

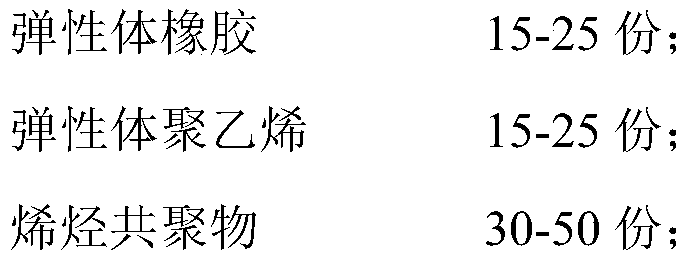

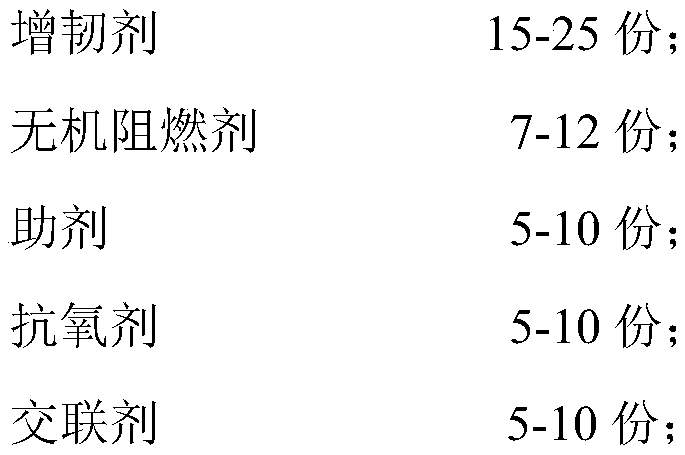

[0040] Embodiment 1 provides a kind of soft polyolefin wire material for new energy vehicle high voltage wire, which includes the following components by weight:

[0041]

[0042] The polyolefin wire material is prepared by irradiation crosslinking; the olefin copolymer is 1,1,1-trifluoro-2-(trifluoromethyl)-4-pentan-2-ol, 1, 3-adamantanediol monoacrylate and acrylonitrile are prepared by free radical copolymerization; the preparation method of the olefin copolymer comprises the following steps: 1,1,1-trifluoro-2-(trifluoromethyl )-4-pentan-2-ol, 1,3-adamantanediol monoacrylate, acrylonitrile, and initiator were added to a high-boiling point solvent, stirred and reacted at 70°C for 3 hours in a nitrogen atmosphere, and then precipitated in water and dried to constant weight in a vacuum oven at 80°C to obtain an olefin copolymer; the 1,1,1-trifluoro-2-(trifluoromethyl)-4-pentan-2-ol, 1, The mass ratio of 3-adamantanediol monoacrylate, acrylonitrile, initiator, and high boil...

Embodiment 2

[0049] Embodiment 2 provides a soft polyolefin wire material for high-voltage wires of new energy vehicles. Its formula and preparation method are basically the same as in Embodiment 1, except that it includes the following components in parts by weight:

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com