High-performance polyphenylene sulfide laminated composite plate material and preparation method thereof

A polyphenylene sulfide layer and composite sheet technology, applied in the direction of lamination, lamination devices, chemical instruments and methods, etc., can solve the problems of poor melt impregnation effect, increased polymer chain rigidity, brittleness, and low impact toughness , to achieve the effect of overcoming insufficient adhesion, broad application prospects, and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh the raw materials according to the following parts by weight:

[0029] 100 parts of polyphenylene sulfide (PPS),

[0030] Glass fiber cloth (area density 400g / m 2 ) 10 copies,

[0031] High temperature resistant nylon PA46 10 parts,

[0032] Compatibility agent MAH-g-SEBS 5 parts;

[0033] (2) Dry the above-mentioned raw materials at 100°C for 2 hours; then stir the polyphenylene sulfide, high temperature resistant nylon, and compatibilizer in a high-speed mixer at high speed for 10 minutes, and mix well;

[0034] (3) Lay and mold the above-mentioned uniformly mixed materials and glass fiber cloth, and heat-press and form at a temperature of 300℃, the hot-pressing time is 0.5h, the hot-pressing pressure is 15MPa, and the pressure-holding conditions are naturally cooled, namely The high-performance polyphenylene sulfide laminated composite board is obtained.

Embodiment 2

[0036] (1) Weigh the raw materials according to the following parts by weight:

[0037] 100 parts of polyphenylene sulfide (PPS),

[0038] Glass fiber cloth (area density 400g / m 2 ) 30 copies,

[0039] 15 parts of high temperature resistant nylon PA6T,

[0040] Compatibility agent MAH-g-PS 10 parts;

[0041] (2) Dry the above raw materials at 120°C for 1 hour; then stir the polyphenylene sulfide, high temperature resistant nylon, and compatibilizer in a high-speed mixer at high speed for 20 minutes, and mix well;

[0042] (3) Lay the above-mentioned uniformly mixed materials and glass fiber cloth in a layered layer and mold, heat-press molding at a temperature of 320℃, the hot-pressing time is 0.5h, the hot-pressing pressure is 20MPa, and it is naturally cooled under the condition of holding pressure. The high-performance polyphenylene sulfide laminated composite board is obtained.

Embodiment 3

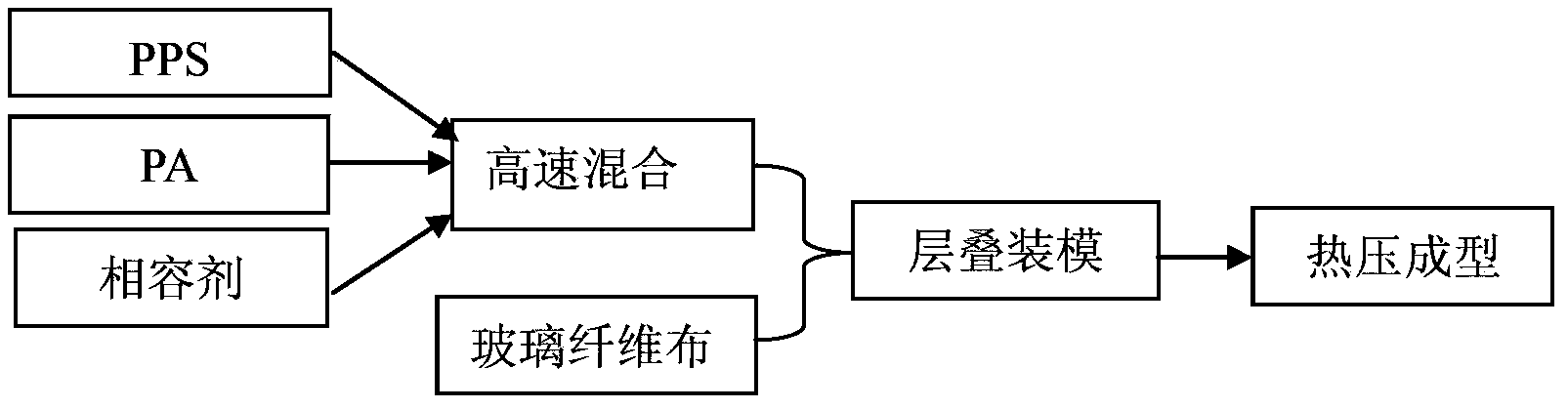

[0044] (1) Such as figure 1 As shown in the steps, first, weigh the raw materials according to the following parts by weight:

[0045] 100 parts of polyphenylene sulfide (PPS),

[0046] Glass fiber cloth (area density 400g / m 2 ) 60 copies,

[0047] High temperature resistant nylon 9T 30 parts,

[0048] Compatibility agent MAH-g-POE 15 parts;

[0049] (2) Then, dry the above-mentioned raw materials at 140°C for 0.5h; then stir the polyphenylene sulfide, high temperature resistant nylon, and compatibilizer in a high-speed mixer at high speed for 30 minutes, and mix well;

[0050] (3) Finally, the above-mentioned uniformly mixed materials and glass fiber cloth are layered, laid and molded, and molded by hot pressing at a temperature of 330°C. The hot pressing time is 1 h, the hot pressing pressure is 30 MPa, and the pressure is maintained for natural cooling. The high-performance polyphenylene sulfide laminated composite board is obtained.

[0051] Table 1

[0052] Performance

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com