Janus type porous silicon dioxide compound nanoparticle and preparing method thereof

A composite nanoparticle and porous silica technology, applied in the field of nanomaterials, can solve the problems of inability to prepare nanoscale, poor particle universality, harsh synthesis conditions, etc., and achieve the effects of easy size regulation, low cost, and mild synthesis conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

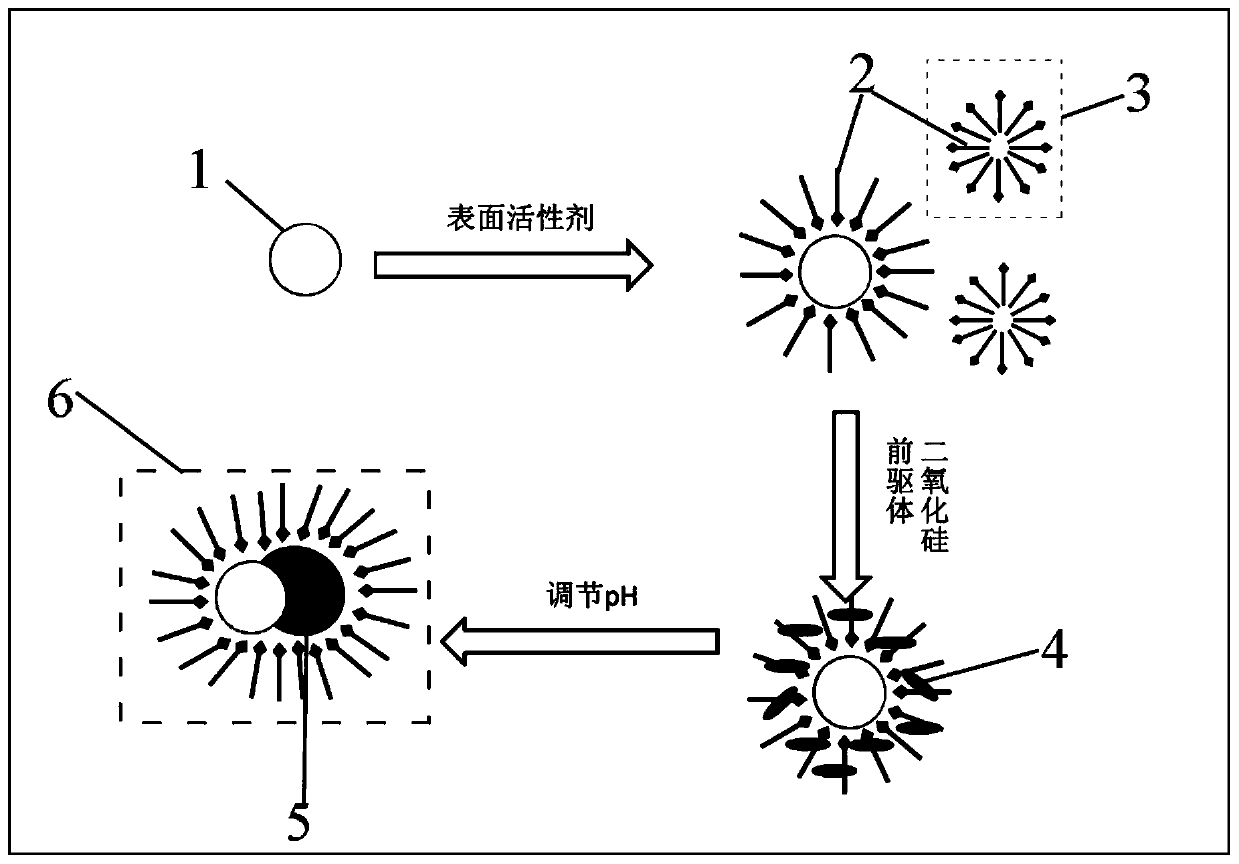

Method used

Image

Examples

Embodiment 1

[0043] Weigh 0.5g of cetyltrimethylammonium bromide and dissolve it in 200mL of deionized water, add 1g of silica nanospheres, and stir mechanically for 3 hours to form a uniform dispersion A;

[0044] Dispersion A was adjusted to pH 8 with ammonia water and mechanically stirred for 2 hours to obtain dispersion B;

[0045] Add 2 g of tetraethyl orthosilicate to dispersion B, heat up to 40°C and stir for 12 hours to obtain a Janus-type porous silica composite nanoparticle dispersion;

[0046] After the obtained Janus type porous silica composite nanoparticle dispersion was purified and spray-dried, Janus type porous silica composite nanoparticles were obtained. In this embodiment, the final product was 1.348g, the theoretical output value was 1.56g, and the yield was 86.4g. %, illustrates that the production rate of the preparation method of the present invention is considerable.

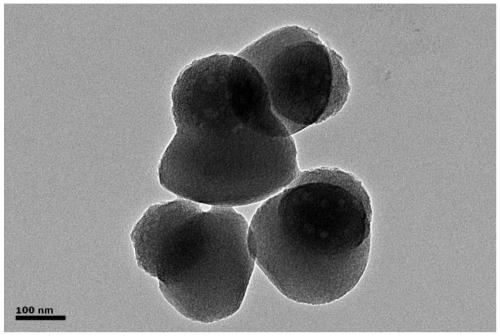

[0047] The Janus type porous silicon dioxide composite nanoparticles prepared in Example 1 were ...

Embodiment 2

[0051] Weigh 1.0 g of cetyltrimethylammonium chloride and dissolve it in 200 mL of deionized water, add 1 g of polyacrylonitrile nanospheres, and stir mechanically for 3 hours to form a uniform dispersion A;

[0052] Adjust the pH of dispersion A to 9 with triethylamine, and mechanically stir for 2 hours to obtain dispersion B;

[0053] Add 4g of methyl orthosilicate to dispersion B, heat up to 80°C and stir for 12 hours to obtain a Janus type porous silica composite nanoparticle dispersion;

[0054] Purify and spray-dry the obtained Janus type porous silica composite nanoparticle dispersion to obtain Janus type polyacrylonitrile-porous silica composite nanoparticle.

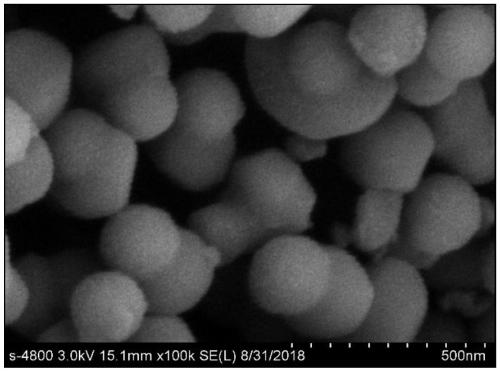

[0055] The Janus type polyacrylonitrile-porous silica composite nanoparticles in embodiment 2 are characterized by scanning electron microscopy and infrared spectroscopy, the results are shown in Figure 5 and Image 6 ,in, Figure 5 It is the SEM picture of the product made in Example 2. It can be seen from ...

Embodiment 3

[0058] Weigh 1.5g of dodecyldimethylbenzyl ammonium chloride and dissolve it in 200mL of deionized water, add 1.2g of alumina nanospheres, and stir mechanically for 3 hours to form a uniform dispersion A;

[0059] Adjust dispersion A to pH = 9 with ammonia water, and mechanically stir for 2 hours to obtain dispersion B;

[0060] Add 1 g of sodium silicate to dispersion B, heat up to 80° C. and stir for 12 hours to obtain a Janus type porous silica composite nanoparticle dispersion;

[0061] Purify and freeze-dry the obtained Janus-type porous silicon dioxide composite nanoparticle dispersion to obtain Janus-type alumina-porous silicon dioxide composite nanoparticle.

[0062] The Janus type alumina-porous silica composite nanoparticle infrared spectrum in embodiment 3 is characterized, and the results are shown in Figure 7 ; Simultaneously the alumina nanosphere in embodiment 3 is compared with Janus type alumina-porous silica composite nanoparticle particle size, the results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com