Composition for preparing flame-retardant liquid silica gel foam and flame-retardant liquid silica gel foam

A technology of liquid silica gel and composition, which is applied in the field of foaming materials, can solve the problems of low foaming ratio, uneven cells, too late colloid, etc., and achieve the effect of uniform cells, high reaction rate, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

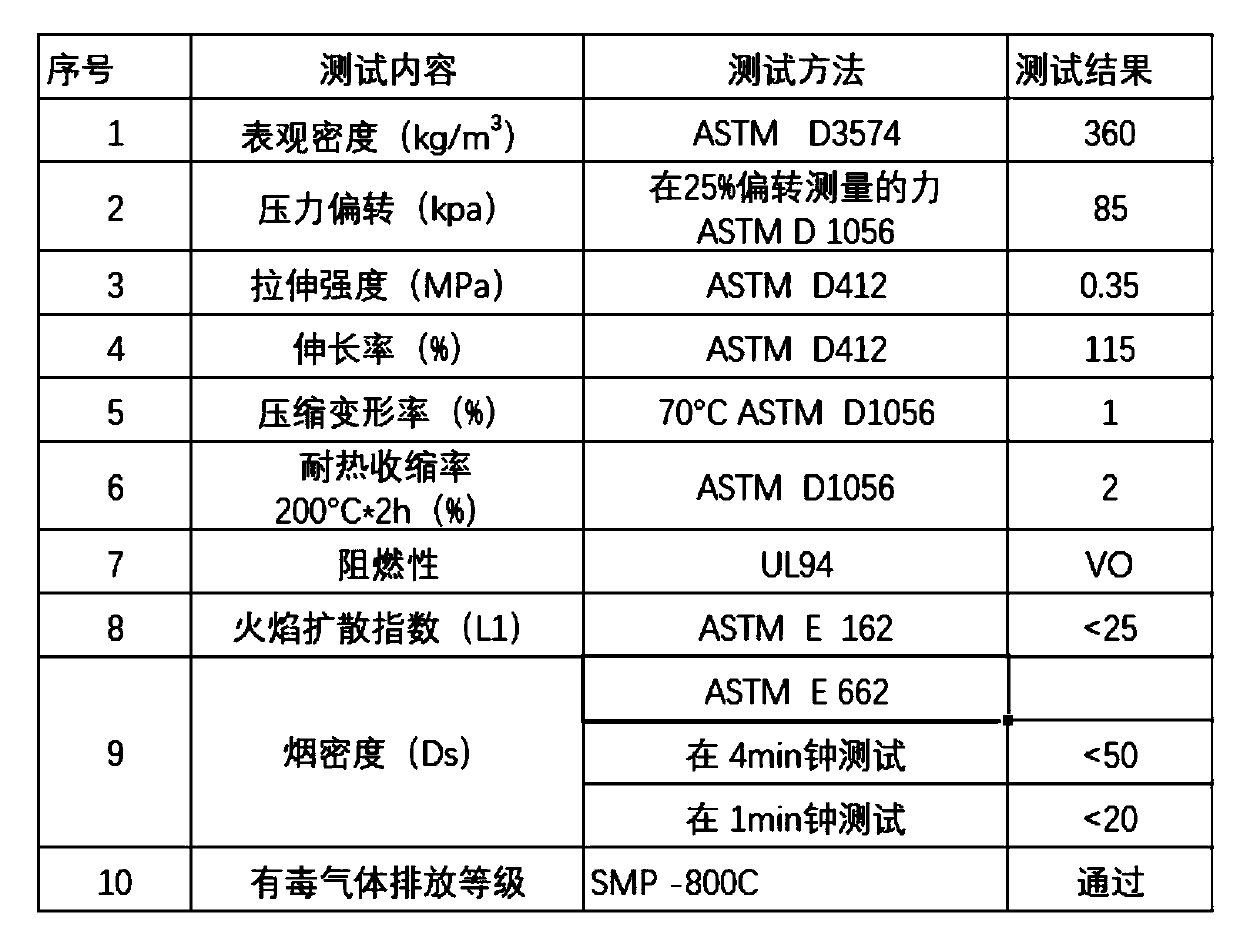

Image

Examples

Embodiment 1

[0034] A flame-retardant liquid silicone foam of the present invention is prepared from the following composition, which consists of material A and material B with a mass ratio of 1:1.

[0035] Among them, in terms of mass, material A includes 65 parts of the first hydroxy vinyl siloxane, 30 parts of the first reinforcing agent, 5 parts of vinyl silicone resin and 0.25 parts of platinum complex.

[0036] The viscosity of the first hydroxy vinyl siloxane is 2500-5000cps, the hydroxyl content: 0.5%-0.8%, and the vinyl content: 0.12-0.32%.

[0037] The first reinforcing agent is a mixture of 180 mesh precipitated silica and 200 mesh meteorological silica.

[0038] Vinyl silicone resin is methyl vinyl resin, its vinyl content: 1.8%-2%, viscosity 1500-2000cps.

[0039] In terms of mass, material B includes 37 parts of second hydroxy vinyl siloxane, 10 parts of second reinforcing agent, 30 parts of hydrogen-containing silicone oil, 15 parts of flame retardant, 18 parts of hydroxy s...

Embodiment 2

[0052] A flame-retardant liquid silicone foam of the present invention is prepared from the following composition, which consists of material A and material B with a mass ratio of 1:1.

[0053] Wherein, in terms of mass, material A includes 20 parts of the first hydroxy vinyl siloxane, 2 parts of the first reinforcing agent, 2 parts of vinyl silicone resin and 0.05 parts of platinum complex.

[0054] In terms of mass, material B includes 23 parts of second hydroxy vinyl siloxane, 5 parts of second reinforcing agent, 1 part of hydrogen-containing silicone oil, 5 parts of flame retardant, 2 parts of hydroxy silicone oil, and 0.01 part of retarder.

[0055] The selection of each component in A material and B material is identical with embodiment 1.

Embodiment 3

[0057] A flame-retardant liquid silicone foam of the present invention is prepared from the following composition, which consists of material A and material B with a mass ratio of 1:1.

[0058] Among them, in terms of mass, material A includes 35 parts of the first hydroxy vinyl siloxane, 10 parts of the first reinforcing agent, 5 parts of vinyl silicone resin and 1 part of platinum complex.

[0059] In terms of mass, material B includes 50 parts of second hydroxy vinyl siloxane, 15 parts of second reinforcing agent, 20 parts of hydrogen-containing silicone oil, 15 parts of flame retardant, 10 parts of hydroxy silicone oil, and 0.5 parts of retarder.

[0060] The selection of each component in A material and B material is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com