Environment-friendly non-autoclaved tubular pile water reducing agent and preparation method thereof

A technology of autoclaved pipe piles and water reducers, which is applied in the field of concrete additives, can solve the problems of further improvement of water reduction effect and easy release of formaldehyde, etc., and achieve the effect of low preparation cost, high social value, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

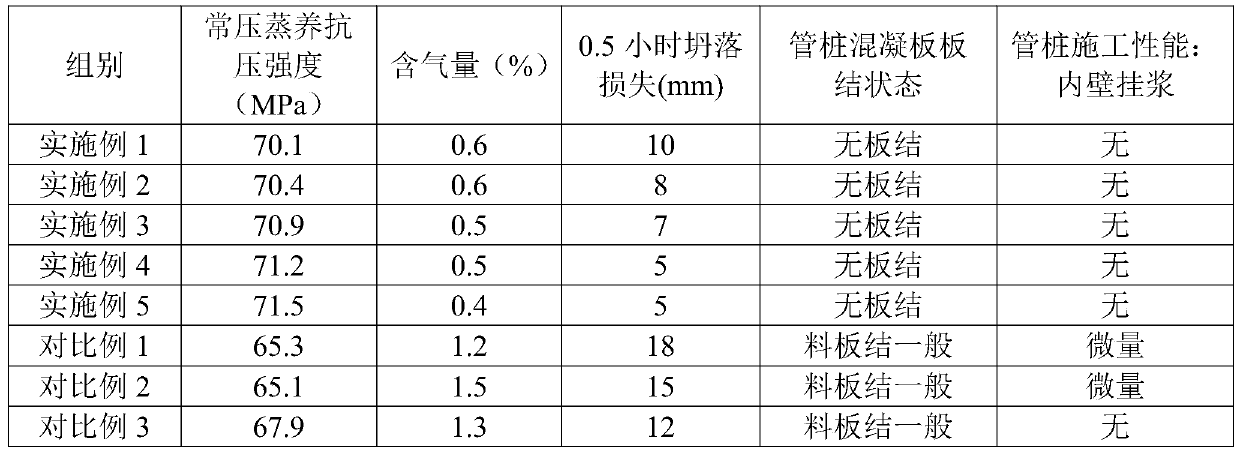

Examples

Embodiment 1

[0029]An environment-friendly autoclaved pipe pile water reducer, characterized in that it includes the following components in parts by weight: 1,3-bis(oxiranylmethyl)-5-(2-propenyl) -10 parts of 1,3,5-triazine-2,4,6(1H,3H,5H)-trione / 4,6-diamino-1,3,5-triazine-2-acetic acid polycondensate, 7-amino-3-vinyl-3-cephine-4-carboxylic acid / 4,4'-diaminostilbene-2,2'-disulfonic acid / polyethylene glycol monoallyl ether / 4 -5 parts of vinyl benzene boronic acid copolymer, 1 part of 9-fluorenic acid, 0.3 parts of azobisisobutyronitrile, 2 parts of bamboo leaf polysaccharide, 35-45 parts of water.

[0030] The 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / The preparation method of 4,6-diamino-1,3,5-triazine-2-acetic acid condensation polymer comprises the following steps: 1,3-bis(oxiranylmethyl)-5-(2 -propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione, 4,6-diamino-1,3,5-triazine-2-acetic acid added into tetrahydrofuran, and sodium hydroxide was added theret...

Embodiment 2

[0034] An environment-friendly autoclaved pipe pile water reducer, characterized in that it includes the following components in parts by weight: 1,3-bis(oxiranylmethyl)-5-(2-propenyl) -13 parts of 1,3,5-triazine-2,4,6(1H,3H,5H)-trione / 4,6-diamino-1,3,5-triazine-2-acetic acid polycondensate, 7-amino-3-vinyl-3-cephine-4-carboxylic acid / 4,4'-diaminostilbene-2,2'-disulfonic acid / polyethylene glycol monoallyl ether / 4 -6 parts of vinyl benzene boronic acid copolymer, 1.5 parts of 9-fluorenic acid, 0.4 parts of azobisisoheptanonitrile, 3 parts of tremella polysaccharide, 37 parts of water.

[0035] The 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / The preparation method of 4,6-diamino-1,3,5-triazine-2-acetic acid condensation polymer comprises the following steps: 1,3-bis(oxiranylmethyl)-5-(2 -propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione, 4,6-diamino-1,3,5-triazine-2-acetic acid added into acetone, and potassium hydroxide was added thereto, sti...

Embodiment 3

[0039] An environment-friendly autoclaved pipe pile water reducer, characterized in that it includes the following components in parts by weight: 1,3-bis(oxiranylmethyl)-5-(2-propenyl) -15 parts of 1,3,5-triazine-2,4,6(1H,3H,5H)-trione / 4,6-diamino-1,3,5-triazine-2-acetic acid polycondensate, 7-amino-3-vinyl-3-cephine-4-carboxylic acid / 4,4'-diaminostilbene-2,2'-disulfonic acid / polyethylene glycol monoallyl ether / 4 - 7 parts of vinyl benzene boronic acid copolymer, 2 parts of 9-fluorenic acid, 0.45 parts of azobisisoheptanonitrile, 3.5 parts of lentinan, 40 parts of water.

[0040] The 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / The preparation method of 4,6-diamino-1,3,5-triazine-2-acetic acid condensation polymer comprises the following steps: 1,3-bis(oxiranylmethyl)-5-(2 -propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione, 4,6-diamino-1,3,5-triazine-2-acetic acid added into chloroform, then add sodium carbonate therein, stir and react at 75°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com