Hydrogen sulfide corrosion inhibitor applied to thermal recovery of thickened oil and preparation method thereof

A heavy oil thermal recovery and corrosion inhibitor technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problem of not many corrosion inhibitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

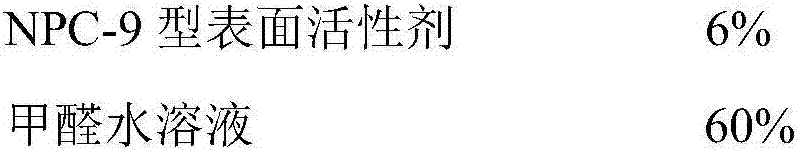

[0025] The formula of the hydrogen sulfide corrosion inhibitor adopted in the thermal recovery of a kind of heavy oil is as follows (mass percentage):

[0026]

[0027]

[0028] According to "SY / T 5673--2000 Performance Evaluation Method of Corrosion Inhibitors for Oilfield Produced Water", the speed of the test piece in the autoclave is 200r / min, the hanging time is 72h, the ambient temperature is set at 160°C, and the corrosion inhibitor is added Drug concentration is 60mg / L. After the hanging test, the test piece was pickled, dried and weighed, and the corrosion inhibition efficiency of the corrosion inhibitor was calculated from the change of the mass of the test piece before and after.

[0029] Table 1 Comparison of corrosion inhibition effects of test pieces

[0030] experiment type

Embodiment 2

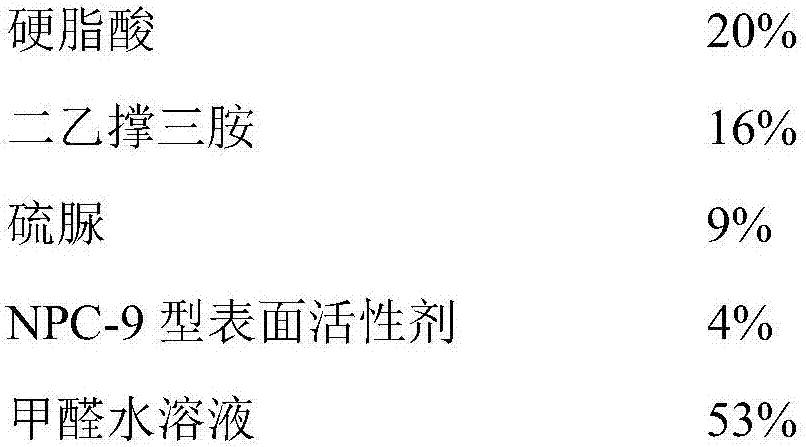

[0032] The formula of the hydrogen sulfide corrosion inhibitor adopted in the thermal recovery of a kind of heavy oil is as follows (mass percentage):

[0033]

[0034] According to "SY / T 5673--2000 Performance Evaluation Method of Corrosion Inhibitors for Oilfield Produced Water", the speed of the test piece in the autoclave is 200r / min, the hanging time is 72h, the ambient temperature is set at 160°C, and the corrosion inhibitor is added Drug concentration is 60mg / L. After the hanging test, the test piece was pickled, dried and weighed, and the corrosion inhibition efficiency of the corrosion inhibitor was calculated from the change of the mass of the test piece before and after.

[0035] Table 2 Comparison of corrosion inhibition effects of test pieces

[0036] experiment type

Embodiment 3

[0038] The formula of the hydrogen sulfide corrosion inhibitor adopted in the thermal recovery of a kind of heavy oil is as follows (mass percentage):

[0039]

[0040] According to "SY / T 5673--2000 Performance Evaluation Method of Corrosion Inhibitors for Oilfield Produced Water", the speed of the test piece in the autoclave is 200r / min, the hanging time is 72h, the ambient temperature is set at 160°C, and the corrosion inhibitor is added Drug concentration is 60mg / L. After the hanging test, the test piece was pickled, dried and weighed, and the corrosion inhibition efficiency of the corrosion inhibitor was calculated from the change of the mass of the test piece before and after.

[0041] Table 3 Comparison of corrosion inhibition effects of test pieces

[0042] experiment type

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com