Weather-resistant PVC decorative film

A decorative film and weather-resistant technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of severe discoloration, decorative film without any process, deterioration of living environment or working environment, etc., to achieve The effect of excellent gloss and acid and alkali resistance, excellent pollution resistance, and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

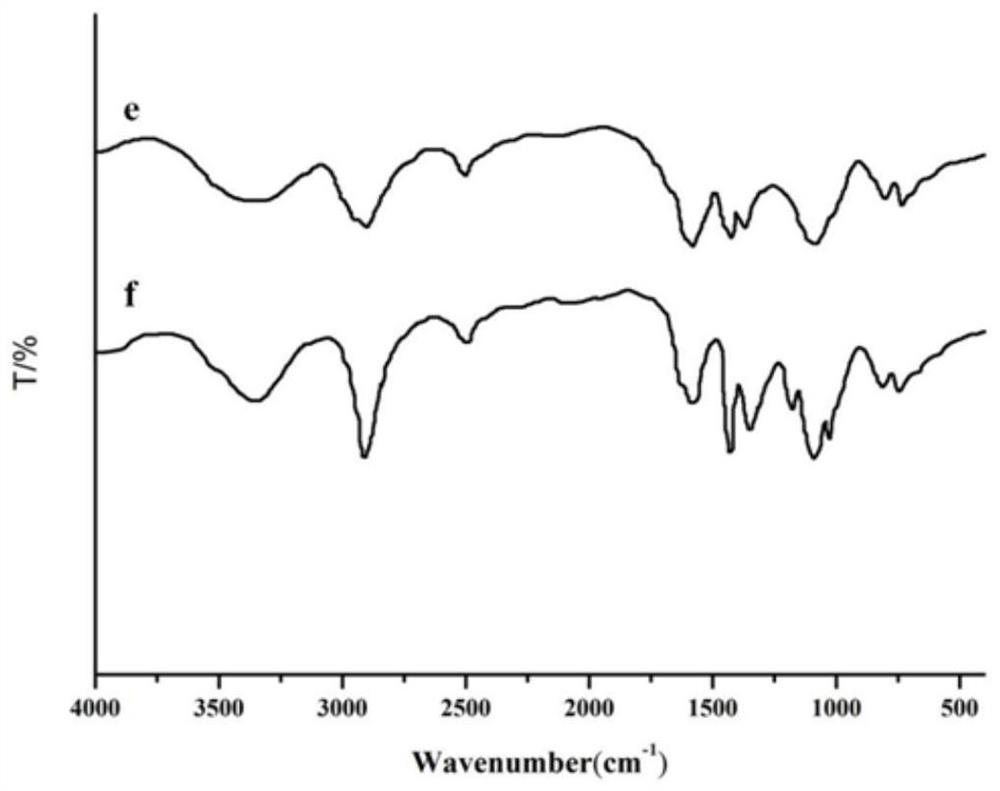

[0043] The invention also discloses a preparation method of a weather-resistant PVC decorative film, the steps of which include:

[0044] Provide PVC base material, and perform high-voltage corona treatment on the surface of PVC base material;

[0045] Provide water-based ink; use the gravure printing method to print the weather-resistant water-based ink on the surface of the PVC bottom substrate to form a water-based ink printing layer;

[0046] Provide a PVDF / PMMA co-extrusion layer, and press the PVDF / PMMA co-extrusion layer on the surface of the water-based ink printing layer through a laminating machine to form PVDF / PMMA.

[0047] Further, in some embodiments of the present invention, the treatment conditions of the high-voltage corona are as follows: the voltage is 7-10 kV, the current is 1.2-2.5 mA, and the vehicle speed is 120-170 m / min.

[0048] Further, in some embodiments of the present invention, the rotational speed of the gravure printing plate in the gravure pr...

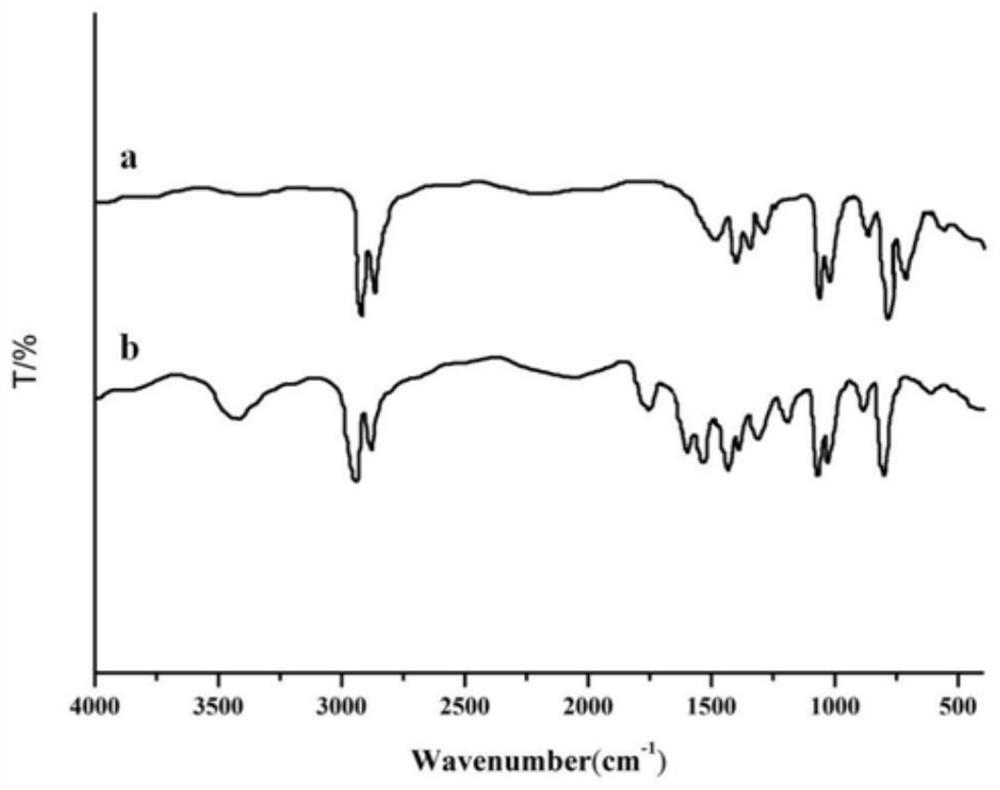

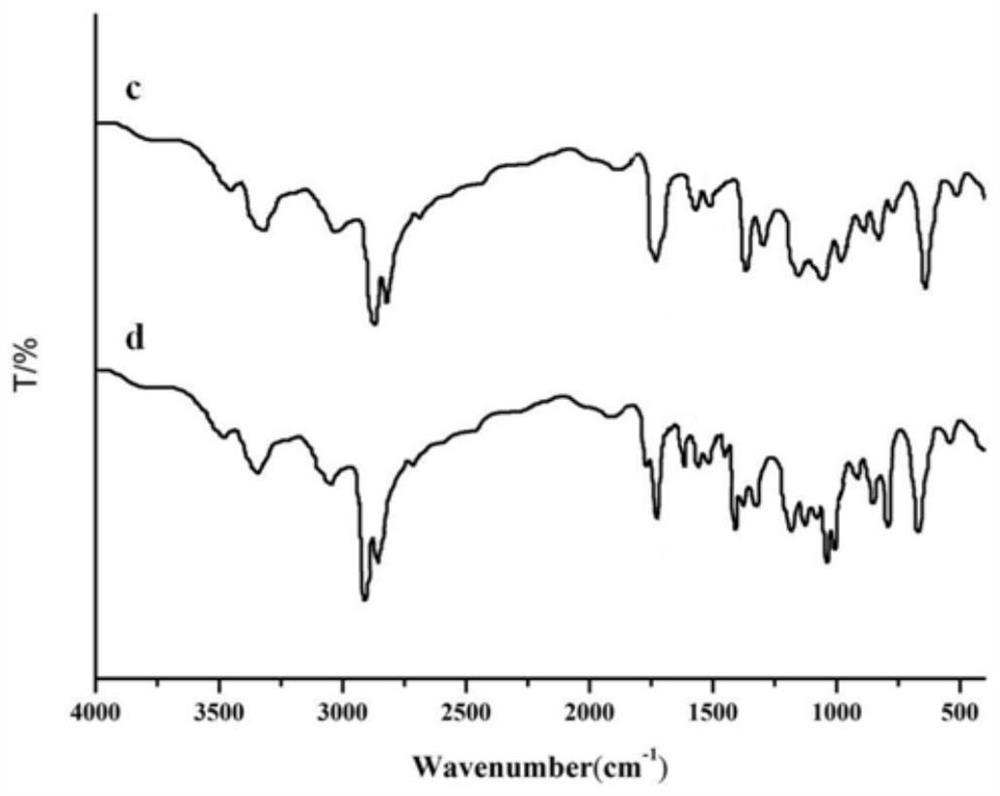

Embodiment 1

[0052] The preparation method of acrylic resin is:

[0053] According to the weight ratio of 1:0.6, the emulsifier (the weight ratio of lauryl alcohol polyoxyethylene ether and sodium lauryl sulfate is 1:2) and deionized water are prepared under the condition of magnetic stirring to obtain the emulsion; the weight ratio is 4:3:1 methyl methacrylate, hydroxyethyl acrylate and styrene monomers were added to the above-mentioned emulsion, wherein the emulsifier was 3.5% of the total monomer weight, and stirred for 40min at 800r / min rotating speed to obtain Emulsion a;

[0054] Mix 30wt% of the emulsion a, 0.15% of the total monomer weight of the buffer and 3 times the total monomer weight of deionized water, add 0.35% of the total monomer weight of ammonium persulfide, and stir and mix at 800r / min. 15min to obtain the emulsion b, then add the remaining 70wt% of the emulsion a and 0.35% of the total monomer weight of ammonium persulfide, heat up to 75 ° C and stir the reaction, ke...

Embodiment 2

[0056] The preparation method of modified acrylic resin is:

[0057] According to the weight ratio of 1:0.6, the emulsifier (the weight ratio of lauryl alcohol polyoxyethylene ether and sodium lauryl sulfate is 1:2) and deionized water are prepared under the condition of magnetic stirring to obtain the emulsion; the weight ratio is 4:3:1 methyl methacrylate, hydroxyethyl acrylate and styrene monomers were added to the above-mentioned emulsion, wherein the emulsifier was 3.5% of the total monomer weight, and stirred for 40min at 800r / min rotating speed to obtain Emulsion a;

[0058] Mix 30wt% of the emulsion a, 0.15% of the total monomer weight of the buffer and 3 times the total monomer weight of deionized water, add 0.35% of the total monomer weight of ammonium persulfide, and stir and mix at 800r / min. 15min to obtain the emulsion b, then add the remaining 70wt% of the emulsion a, 4.5% of the total weight of the modified organosilicon and 0.45% of the total weight of the mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| freshness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com