POE graft polymer for enhancing PP printing performance and preparation process thereof

A technology of grafting polymers and performance, applied in the field of polymers, can solve the problems of low critical surface tension of PP, poor ink affinity, limited application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The proportioning ratio of parts by weight of embodiment 1 (using POE to connect the plate polymer) is Table 2:

[0026] Table 2. The weight ratio table of embodiment 1 (using POE plate polymer)

[0027] PP 100 POE connection sheet (freshly prepared) 6 Superfine talcum powder (2500 mesh) 30 Antioxidant 1010 0.20~0.25 Antioxidant DLTP 0.30~0.35 Zinc stearate 0.40~0.60

Embodiment 2

[0028] The proportioning ratio table 3 of the parts by weight of embodiment 2 (with other modifying agents):

[0029] Table 3. The proportioning table of parts by weight of embodiment 2 (with other modifiers)

[0030]

[0031]

Embodiment 3

[0032] Embodiment 3, the recipe preparation process of test: comprise the steps:

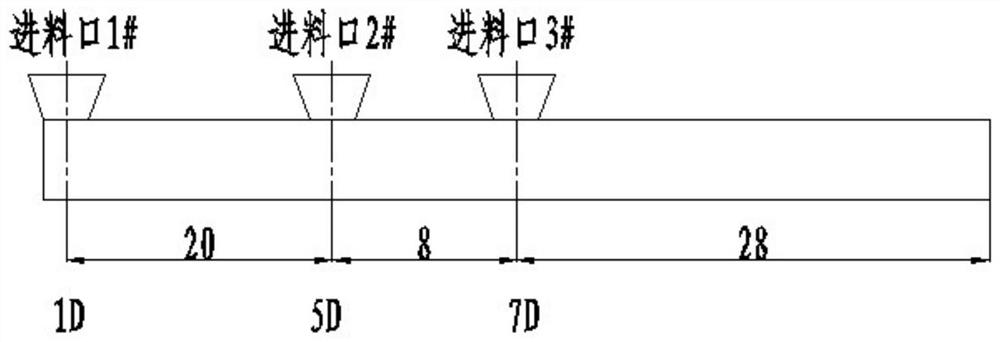

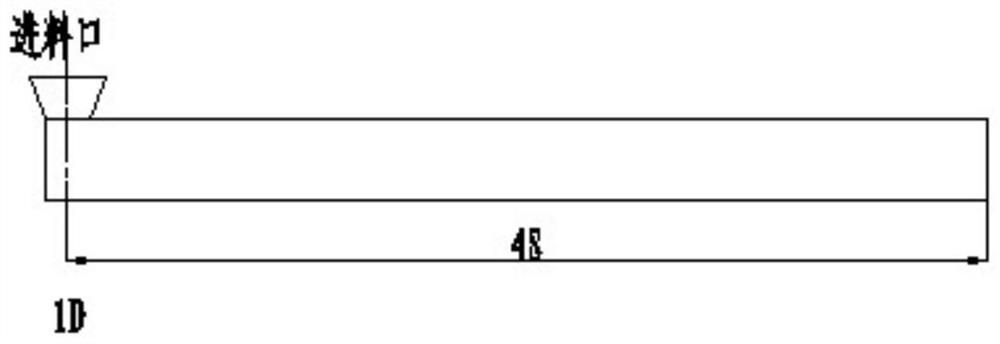

[0033] (1) if figure 2 , extruded on a twin-screw extruder with a length-to-diameter ratio of L / D=48. There are 12 sections on the extruder, 3 feed ports, and 1 feed port is located at extruder 1D;

[0034] (2) After weighing each component of the test formula according to the formula ratio, put it into a high-speed mixer and stir for 5 to 6 minutes, and discharge it for later use;

[0035] (3) Add the mixed PP compound to the feed port of the twin-screw extruder with a feed rate of 150r / min at a feed rate of 95kg / n

[0036] (4) Processing temperature of each section:

[0037] Section 1 Section 2 Section 3 Section 4 130℃~140℃ 180℃~190℃ 190℃~200℃ 200℃~210℃ Section 5 Section 6 Section 7 Section 8 210℃~220℃ 210℃~220℃ 220℃~230℃ 220℃~230℃ Section 9 Section 10 Section 11 Section 12 200℃~210℃ 190℃~200℃ 180℃~190℃ 160℃~170℃

[0038] Typica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com