A kind of ultraviolet light and moisture dual curing polyurethane hot-melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and dual-curing technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as low initial adhesion, slow increase in adhesion, and reduced production efficiency. Achieve high adhesion, increase functionality, and speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

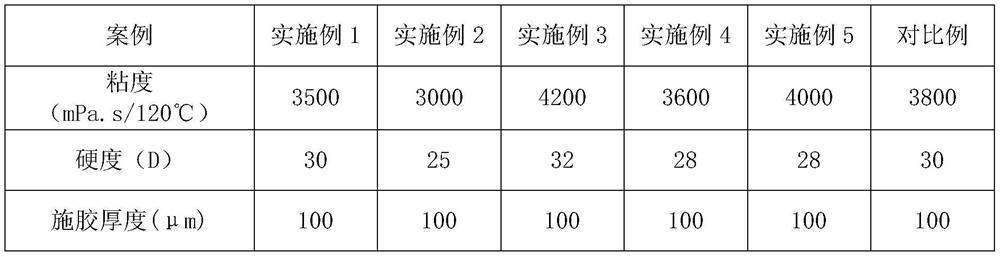

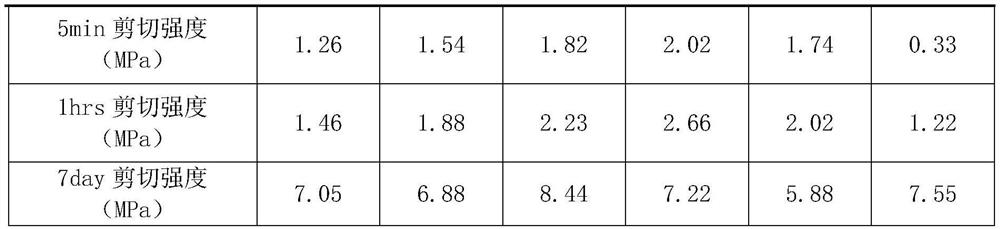

Examples

Embodiment 1

[0025] A preparation method of UV pressure-sensitive / moisture dual-cure polyurethane hot-melt adhesive, the steps are as follows:

[0026] (1) Put 20 parts of thermoplastic EVA resin, 30 parts of polybutylene adipate diol with a molecular weight of 2000, 20 parts of PPG with a molecular weight of 1000, and 1 part of trimethylolethane at 95 ° C and -0.1 MPa vacuum conditions , stirring and dehydrating at 300r / min for 2hrs.

[0027] (2) Lower the temperature of the dehydration mixture in step (1) to 80°C, add 5 parts of hydroxyethyl acrylate monomer, 20 parts of polyisocyanate, and 0.5 parts of dibutyltin dilaurate, and stir the reaction under nitrogen atmosphere 2hrs, get the prepolymer;

[0028] (3) Add 2 parts of TPO photoinitiator, 1 part of A1160, 0.4 parts of BYK 066N to the prepolymer, and stir and defoam under the vacuum state of -0.1MPa to obtain a polyurethane hot melt with UV / moisture dual curing glue.

Embodiment 2

[0030] A preparation method of UV pressure-sensitive / moisture dual-cure polyurethane hot-melt adhesive, the steps are as follows:

[0031] (1) 30 parts of thermoplastic acrylic resin, 30 parts of polypentylene adipate diol with a molecular weight of 2000, 30 parts of PPG with a molecular weight of 1000, and 2 parts of trimethylolpropane at 95 ° C and -0.1 MPa vacuum conditions, Stir and dehydrate at 300r / min for 2hrs.

[0032] (2) Cool down the dehydration mixture in step (1) to 80°C, add 7 parts of hydroxyethyl methacrylate monomer, 20 parts of HDI, 0.5 parts of stannous octoate, and stir for 2 hrs under nitrogen atmosphere , to obtain the prepolymer;

[0033] (3) Add 3 parts of TPO photoinitiator, 1 part of KH580, 0.6 parts of BYK 1790 to the prepolymer, stir and defoam under the vacuum state of -0.1MPa to obtain a polyurethane hot melt with UV / moisture dual curing glue.

Embodiment 3

[0035] A preparation method of UV pressure-sensitive / moisture dual-cure polyurethane hot-melt adhesive, the steps are as follows:

[0036] (1) 40 parts of thermoplastic TPU resin, 30 parts of polyhexamethylene adipate diol with a molecular weight of 2000, 35 parts of PPG with a molecular weight of 1000, and 3 parts of glycerol were placed at 95°C and -0.1MPa under vacuum conditions at 300r / min stirring dehydration 2hrs.

[0037] (2) Cool down the dehydration mixture in step (1) to 80°C, add 9 parts of hydroxypropyl acrylate monomer, 20 parts of MDI, 0.5 parts of dibutyltin dilaurate, and stir for 2hrs under nitrogen atmosphere , to obtain the prepolymer.

[0038] (3) Add 4 parts of 184 photoinitiator, 1 part of KH580, 0.2 parts of BYK A535 to the prepolymer in a vacuum state of -0.1MPa, stir and defoam to obtain a polyurethane hot melt with UV / moisture dual curing glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com