Water-base tape casting slurry and water-base tape casting wet method for preparing multilayer chip component

A water-based casting, multi-layer chip technology, applied in the field of chip ceramic electronics, can solve the problems of easy cracking of the green body, poor diaphragm effect, poor powder wettability, etc., to reduce production costs and reduce ball milling time. , the effect of good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

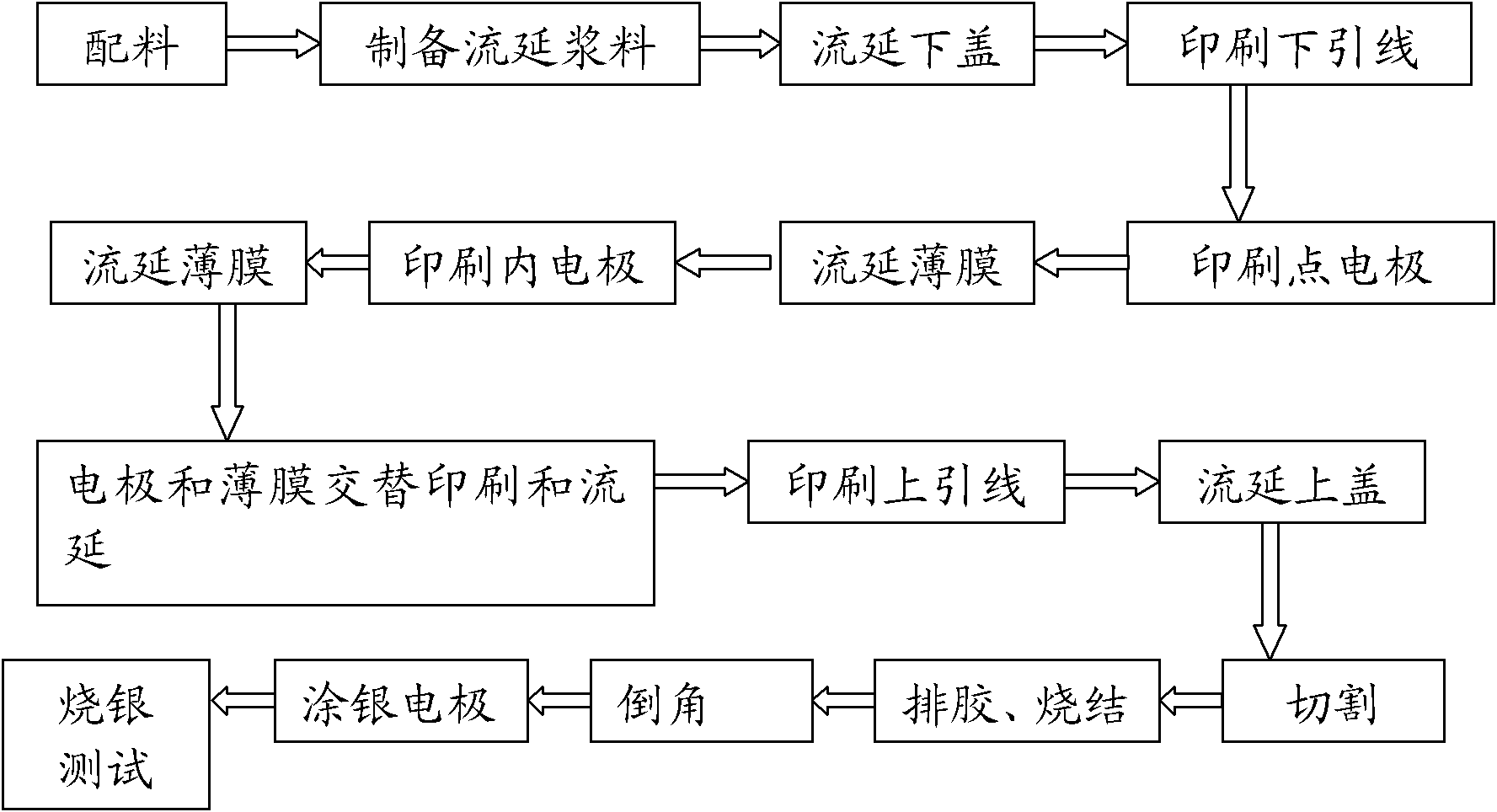

[0061] Water-based casting slurry and water-based casting wet method for preparing multilayer chip inductors:

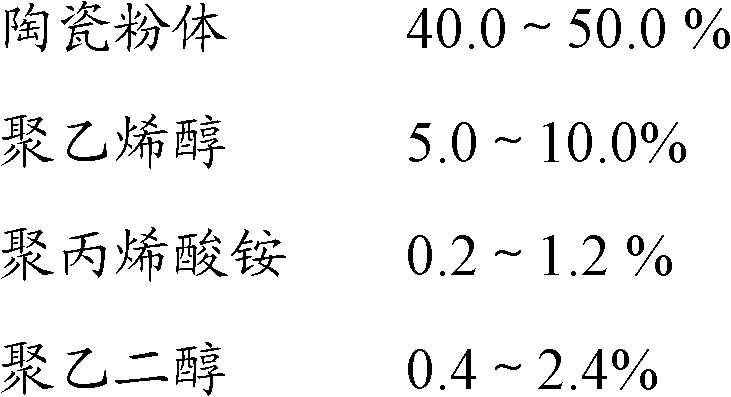

[0062] (1) The formula of water-based casting slurry is weighed ceramic powder, polyvinyl alcohol, ammonium polyacrylate, polyethylene glycol, ethylene glycol butyl ether, acrylic resin, defoamer and water components, first Mix water with ammonium polyacrylate and ceramic powder and ball mill for 12 hours, adjust the pH value to 9.5 at the same time, then add polyvinyl alcohol, polyethylene glycol, defoamer and ball mill again for 24 hours to produce water-based cast slurry The formula of the water-based casting slurry is: based on the total weight of the water-based casting slurry as 100%, the weight percentage of ceramic powder is 50.0%, the weight percentage of polyvinyl alcohol is 9%, polyacrylic acid The weight percentage of ammonium is 2%, the weight percentage of polyethylene glycol is 1%, the cosolvent ethylene glycol butyl ether is 9.3%, the acrylic resin is...

Embodiment 2 to Embodiment 6

[0073] Water-based casting slurry and water-based casting wet method for preparing multilayer chip inductors:

[0074] Referring to the formula of water-based casting in Example 1, keep the contents of ceramic powder, ammonium polyacrylate, polyethylene glycol, ethylene glycol butyl ether, acrylic resin and water components unchanged, and adjust the content of polyvinyl alcohol respectively To 11%, 10%, 9%, 8%, 7%. The water-based casting slurries prepared in Examples 2 to 6 were respectively cast to prepare thin strips, and the properties of the thin strips are shown in Table 2 below.

[0075] Table 2

[0076]

[0077] It can be seen from Table 2 that the viscosity of water-based casting slurry is jointly determined by the content of binder and ceramic powder. If the binder content is too low, the strength of the thin strip will be low; if the binder content is too high, the strength of the thin strip will be increased, but the pores of the slurry will not be easily elim...

Embodiment 7 to Embodiment 11

[0079] Water-based casting slurry and water-based casting wet method for preparing multilayer chip inductors:

[0080] Referring to the formula of water-based casting in Example 1, keep the content of ceramic powder, ammonium polyacrylate, polyvinyl alcohol, ethylene glycol butyl ether, acrylic resin and water components unchanged, and adjust the content of polyethylene glycol respectively To 0.2%, 0.4%, 0.6%, 0.8%, 1.0%. The water-based casting slurries prepared in Examples 7 to 11 were respectively cast to prepare thin strips, and the properties of the thin strips are shown in Table 3 below.

[0081] table 3

[0082]

[0083] It can be seen from Table 3 that the content of polyethylene glycol affects the related properties of the thin tape prepared by casting using the water-based casting slurry containing polyethylene glycol, such as affecting the flexibility and flatness of the thin tape. As the content of polyethylene glycol increases, the flexibility of the thin tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com