Silicon-dioxide aerogel heat insulation composite material and preparation method thereof

A technology of silica and composite materials, applied in the field of material preparation, can solve the problems of increasing the solid heat conduction of the material, the influence of the mechanical properties of the material, and the non-uniform structure, so as to achieve the effect of firm interface bonding, improved mechanical properties, and enhanced bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

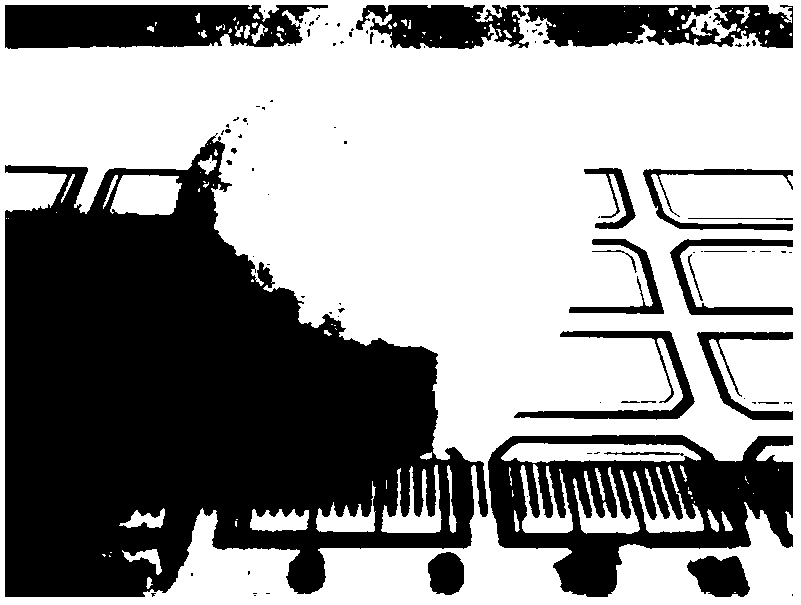

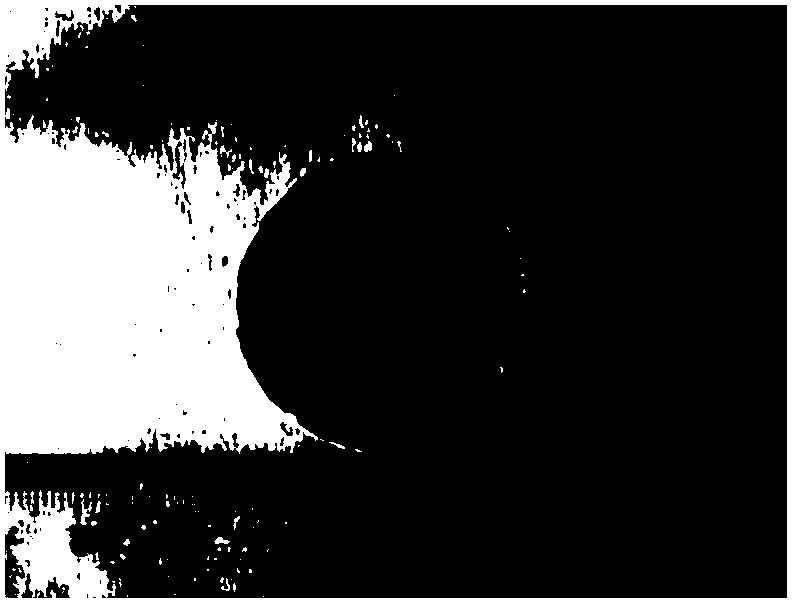

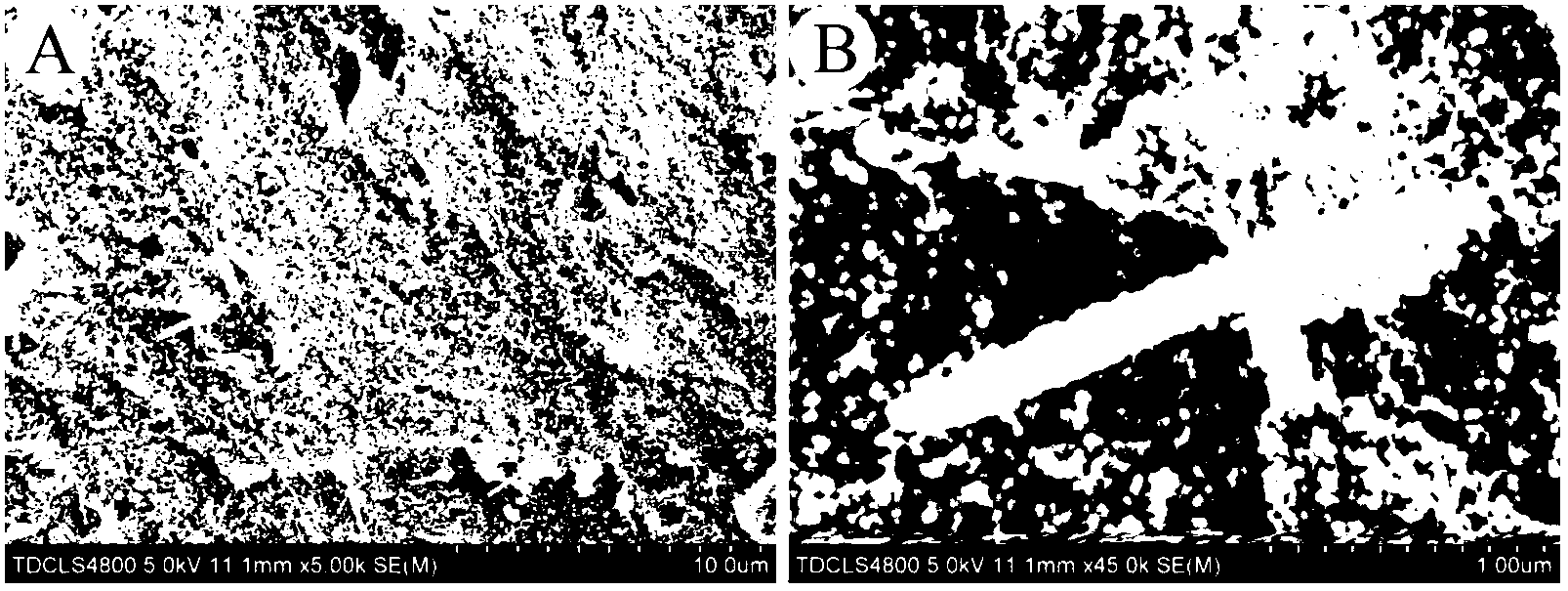

Method used

Image

Examples

Embodiment 1

[0030] Prepare some 0.1mol / L nitric acid solution, weigh the sepiolite fiber according to the acid solution to fiber mass ratio of 14, add the weighed sepiolite fiber into the prepared nitric acid solution, and mechanically stir for 12 hours. Filtrating the acid-treated sepiolite suspension, stirring and dispersing the obtained filter cake in distilled water for washing, repeatedly washing with distilled water for 3 times, then washing with ethanol once, and drying the washed sepiolite fibers; Weigh the acid-treated sepiolite fiber according to the mass ratio of alkali solution to fiber of 10, add the weighed fiber to 1mol / L NaOH solution for 1 hour, and wash the sepiolite fiber repeatedly with distilled water for 3 times after alkali treatment , and then washed once with ethanol, the mass ratio of the washing solution to the fiber was 15 in each washing process, and the washed sepiolite fiber was dried at 80° C. for use. Tetraethyl orthosilicate, ethanol, water and 0.15mol / L ...

Embodiment 2

[0033] Prepare some 2mol / L hydrochloric acid solution, weigh the attapulgite fiber according to the acid solution to fiber mass ratio of 20, add the weighed attapulgite fiber into the prepared hydrochloric acid solution, and mechanically stir for 36 hours. Filtrating the attapulgite suspension after the acid treatment, stirring and dispersing the obtained filter cake in distilled water for washing, repeatedly washing with distilled water for 5 times, then washing twice with ethanol, and drying the cleaned attapulgite fiber; Weigh the acid-treated sepiolite fiber according to the mass ratio of the alkali solution to the fiber at 8, add the weighed fiber to a 0.1mol / L KOH solution for 0.5h, and repeat the alkali-treated attapulgite fiber with distilled water Washing 5 times, and then washing twice with ethanol, the mass ratio of the washing solution to the fiber is 10 in each washing process, and the attapulgite fiber after cleaning is dried at 80° C. for use. Tetraethyl orthosi...

Embodiment 3

[0036] Prepare a number of 1mol / L nitric acid solutions, weigh the sepiolite fibers according to the mass ratio of the acid solution to the fiber being 8, add the weighed sepiolite fibers into the prepared nitric acid solution, and stir for 48 hours. Filter the sepiolite suspension after the acid treatment, stir and disperse the obtained filter cake in distilled water, wash once with distilled water, and wash three times with ethanol. Dry the cleaned sepiolite fiber; weigh the acid-treated sepiolite fiber according to the alkali solution and fiber mass ratio of 5, add the weighed fiber to 0.5mol / L NaOH solution for 2h, and After the alkali treatment, the sepiolite fiber was repeatedly washed with distilled water for 4 times, and then washed with ethanol for 3 times. The mass ratio of the washing liquid to the fiber in each washing process was 25, and the cleaned sepiolite fiber was dried at 80°C. Dry and set aside. Tetraethyl orthosilicate, ethanol, water and 0.15mol / L nitric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com