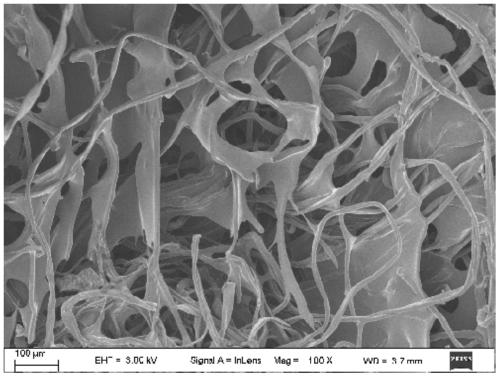

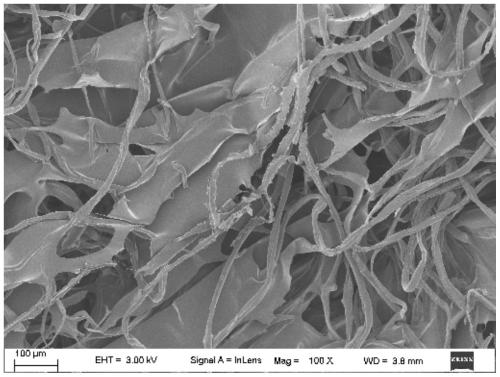

Three-dimensional fiber-based composite aerogel type adsorbent preparation method

A composite aerogel, fiber-based technology, used in chemical instruments and methods, adsorbed water/sewage treatment, alkali metal compounds, etc. The process is complicated and complicated, so as to achieve the effect of lasting maintenance of internal pore structure, lasting recycling, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, cut 3g of cotton fiber into 1-5mm, and selectively oxidize it with sodium periodate. The mass-volume concentration of sodium periodate solution is 8g / L, the temperature is 45°C, the bath ratio is 1:40, and the reaction is protected from light. After 4 hours, the fibers were filtered out after the reaction, washed and vacuum-dried to obtain 2.88 g of dialdehyde-based cotton fibers. Then the dialdehyde-based cotton fiber was placed in 100 mL of urea / dimethylformamide solution, wherein the urea content was 15 g, and mechanically stirred at room temperature for 1 h to form a homogeneous suspension. Dissolve 10g of metaphosphoric acid in 60mL of deionized water, keep stirring for 2h, then mix with the above-mentioned dialdehyde-based cotton fiber suspension, react at 120°C for 2h, filter out the fiber, centrifuge and wash the fiber with ethanol and deionized water Samples were dried under vacuum at 60°C to obtain modified cotton fibers. 5 g of chitosan powder with a ...

Embodiment 2

[0027] First cut 2g of bamboo pulp fibers into 3-5mm, and selectively oxidize it with sodium periodate, the mass-volume concentration of sodium periodate solution is 5g / L, the temperature is 40°C, the bath ratio is 1:30, and it is protected from light After 2 hours of reaction, the fibers were filtered out after the reaction, washed and vacuum-dried to obtain 1.82 g of dialdehyde-based bamboo pulp fibers. Then the above-mentioned dialdehyde-based bamboo pulp fiber was placed in 80 mL of urea / dimethylformamide solution, wherein the urea content was 10 g, and mechanically stirred at room temperature for 1 h to form a homogeneous suspension. Dissolve 6 g of metaphosphoric acid in 40 mL of deionized water, keep stirring for 2 h, then mix it with the above dialdehyde-based bamboo pulp fiber suspension, react at 100°C for 2 h, filter out the fibers, centrifuge and wash with ethanol and deionized water Fiber samples were dried under vacuum at 60°C to obtain modified bamboo pulp fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com