Electrode preparation process for depositing diamond abrasive tool with electric sparks

A technology of electric spark deposition and diamond, which is applied in metal processing equipment, grinding/polishing equipment, grinding equipment, etc., can solve the problems of inability to obtain high abrasive concentration, poor process repeatability, easy oxidation and failure electrode resistance, etc., to achieve High density, uniformity and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

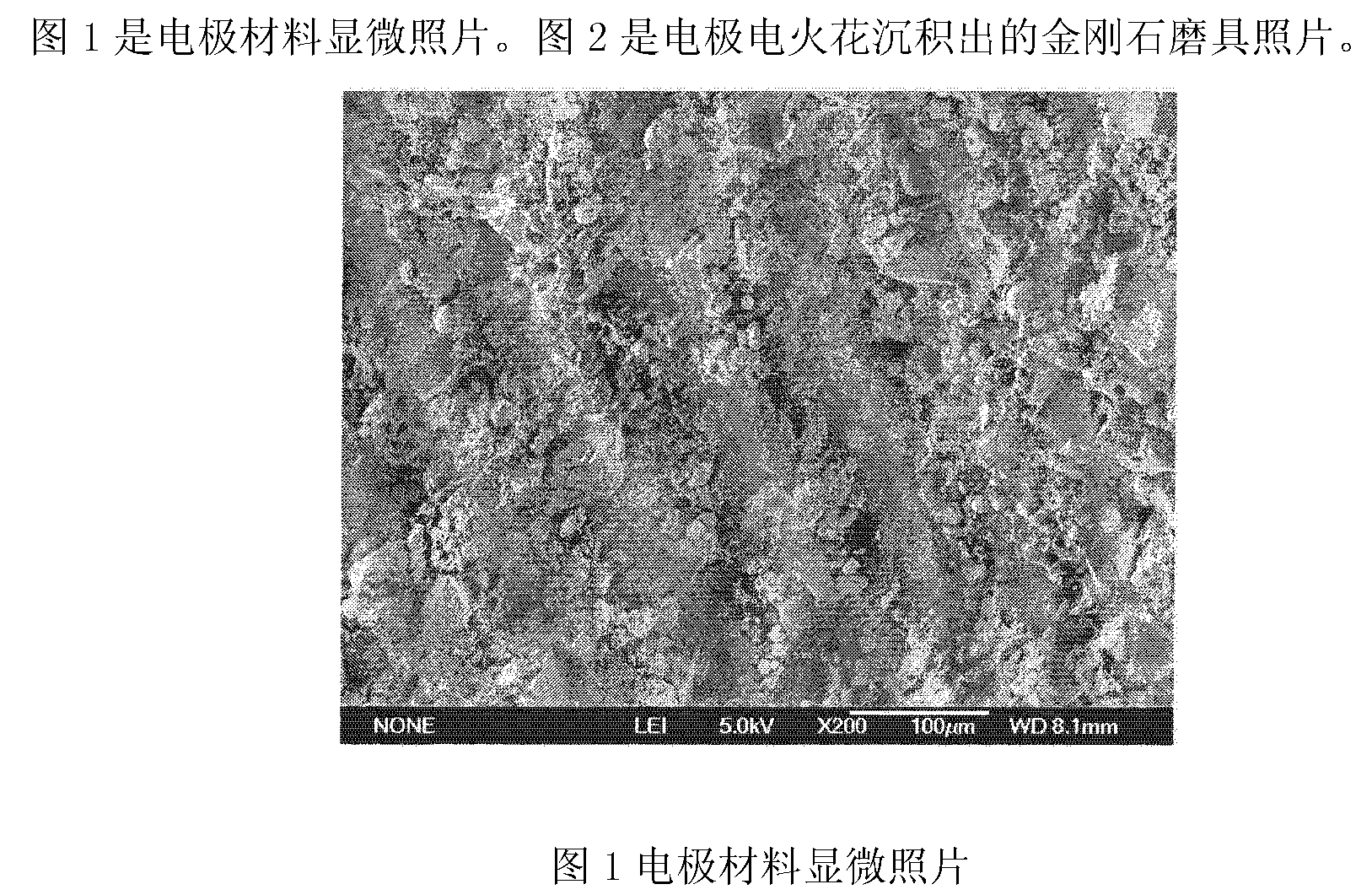

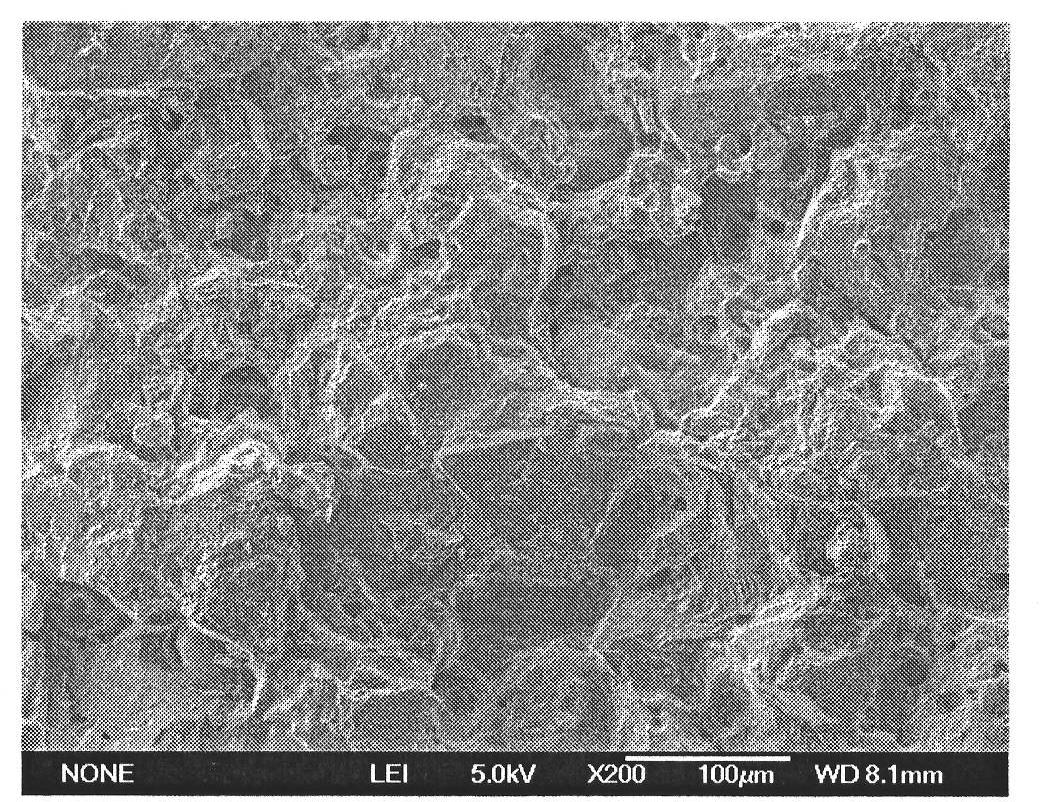

Image

Examples

Embodiment Construction

[0013] Soak the diamond abrasive in absolute ethanol and clean it with ultrasonic waves for one hour. The ultrasonic frequency is 2000 Hz and the power is 200 W. The diamonds are filtered out and dried for later use.

[0014] Soak the diamond after surface cleaning in the industrial aluminum sol with a concentration of 30wt% and a pH value of 3 for 5 minutes, remove the abrasive with a copper net, dry the abrasive at room temperature for 1 hour, and then dry it in an oven at 80°C for 1 hour.

[0015] Then repeat the steps of the above-mentioned sol impregnation and drying process twice

[0016] Put the surface-modified diamond into a box furnace and heat it up to 700°C at a rate of 5°C per minute for one hour, then cool down with the furnace to obtain a surface-coated Al 2 o 3 Coated diamond abrasive, spare.

[0017] Mix diamond abrasive, cobalt powder, copper powder, tungsten carbide powder, and silver powder evenly under ball milling conditions in a mass ratio of 25:20:40:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com