Tobacco flake sorting method based on flake-shaped structure grouping processing

A technology of slices and slices, which is applied in the field of sorting smoke slices based on slice structure grouping processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

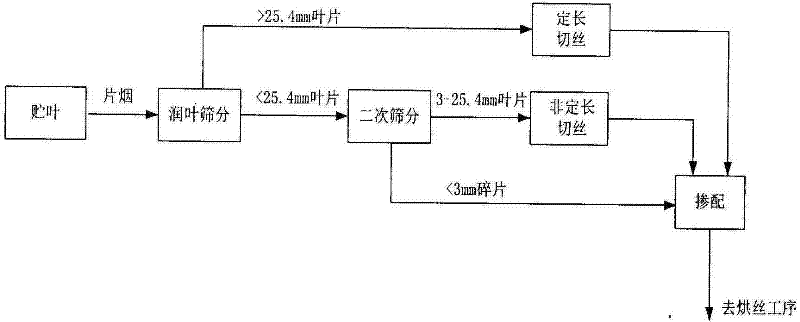

[0025] Such as figure 1 Shown: technological process of the present invention and equipment used are further described below in conjunction with accompanying drawing:

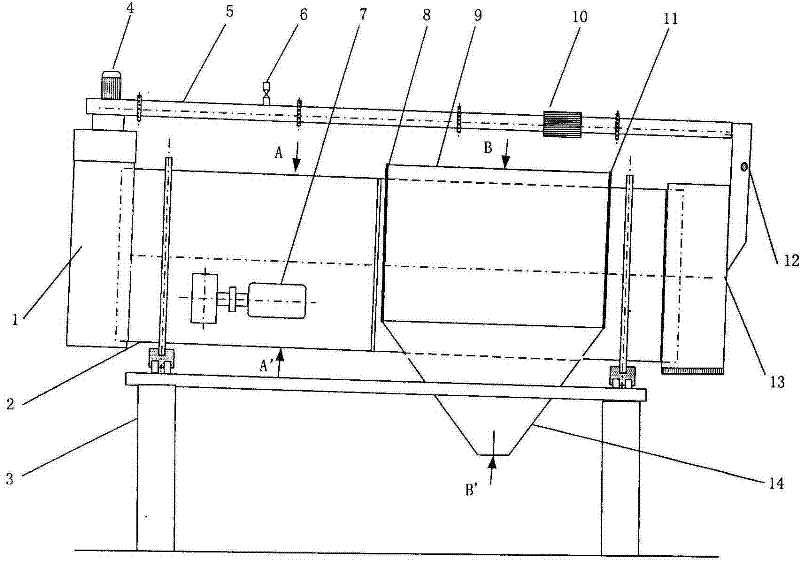

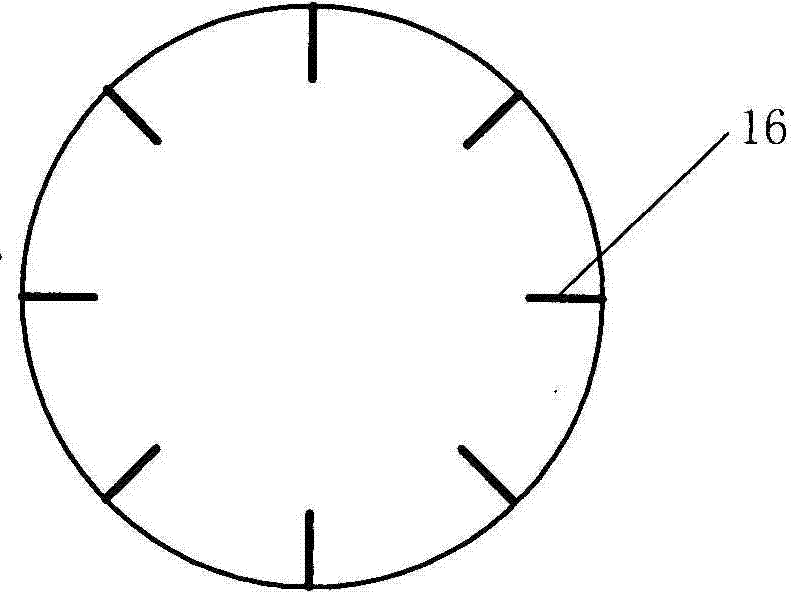

[0026] A group of laminar tobacco output from the leaf storage cabinet, the laminar tobacco is passed through the drum type moistening and screening device (see figure 2 , 3 , 4) After that, it is classified into blades larger than 25.4mm and blades smaller than 25.4mm; blades larger than 25.4mm are sent to the shredding unit, and the shredding unit adopts the length-limited shredding mode; blades smaller than 25.4mm are further subjected to secondary Screening, sieving into blades less than 3mm and 3-25.4mm blades; the 3-25.4mm blades from the secondary screening are sent to another shredding unit, which adopts an unlimited length shredding mode; sieving The leaves smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com