Preparing method of Ti Al-based alloy plate

A technology based on alloys and plates, which is applied in the field of preparation of alloy plates, can solve the problems of interstitial element contamination such as impurities such as oxygen, coarse grain structure, difficult processing and forming, etc., to avoid defects in as-cast structure, fine grain structure, Ease of plastic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

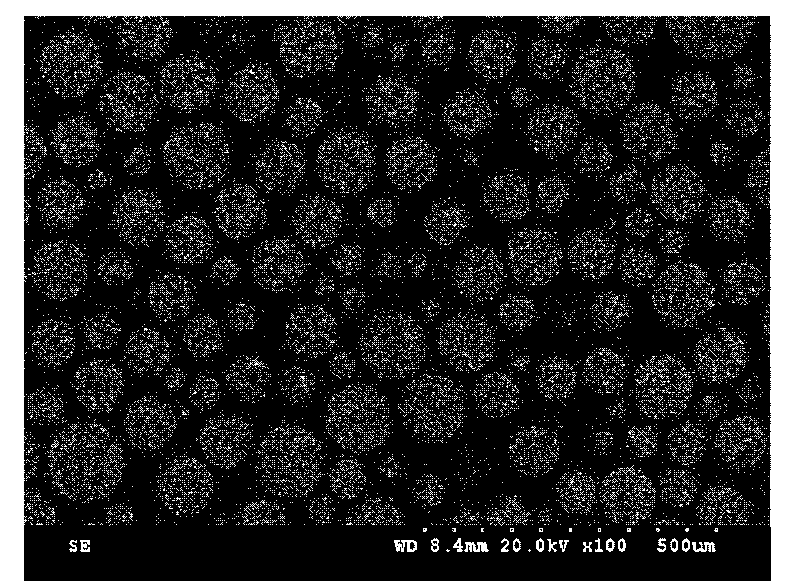

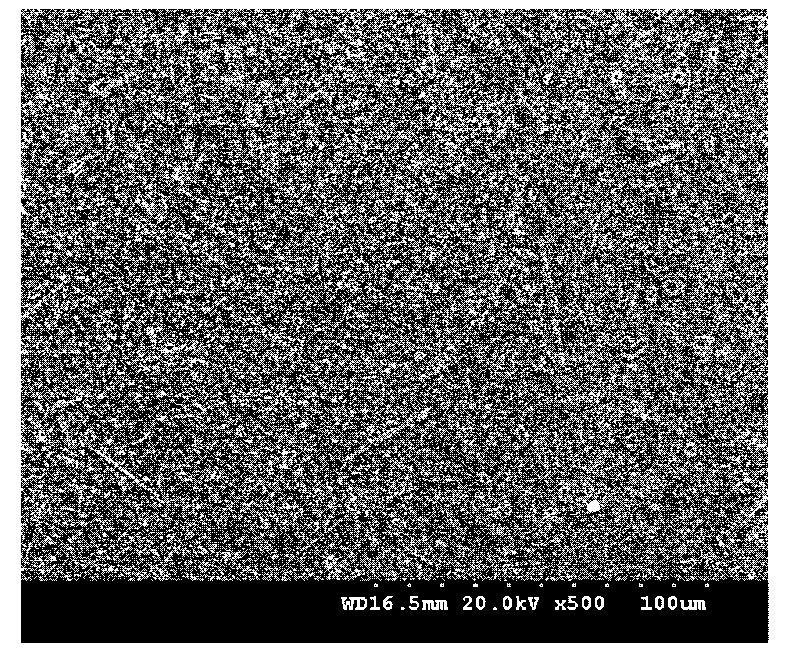

[0009] Specific Embodiment 1: The preparation method of the TiAl-based alloy plate in this embodiment is realized according to the following steps: 1. Use pure titanium particles with a diameter of 50-150 μm to be directly deposited in a steel mold to form a porous titanium preform; 2. Al-Si The alloy ingot is wire-cut into a block with the shape and size of the steel mold, and then placed on the porous titanium preform, and then placed in a vacuum hot-pressing sintering furnace, vacuumed to 0.001-0.01Pa, and then heated at 10-20°C / Raise the temperature to 590-640°C at a rate of 1 min and keep it warm for 30-120 min, then pressurize to 5-30 MPa, keep the pressure for 10-30 min, and then keep the pressure and cool to room temperature to obtain a Ti-Al bimetallic composite; 3. Ti-Al The bimetallic composite body is cold-rolled to obtain a Ti-Al bimetallic composite plate with a thickness of 1-3mm; 4. The Ti-Al bimetallic composite plate is placed in a vacuum hot-pressing sinteri...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that step 1 uses pure titanium particles with a diameter of 60-140 μm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment differs from Embodiment 1 in that step 1 uses pure titanium particles with a diameter of 80 μm. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com