Gold nanorod vertical array and preparing method thereof

A technology of gold nanorods and arrays, which is applied in the field of vertical arrays of gold nanorods and its preparation, can solve the problems of small-scale gold nanorod arrays, discontinuous structure distribution, and inability to locate, and achieve wide application value and high structural uniformity , easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

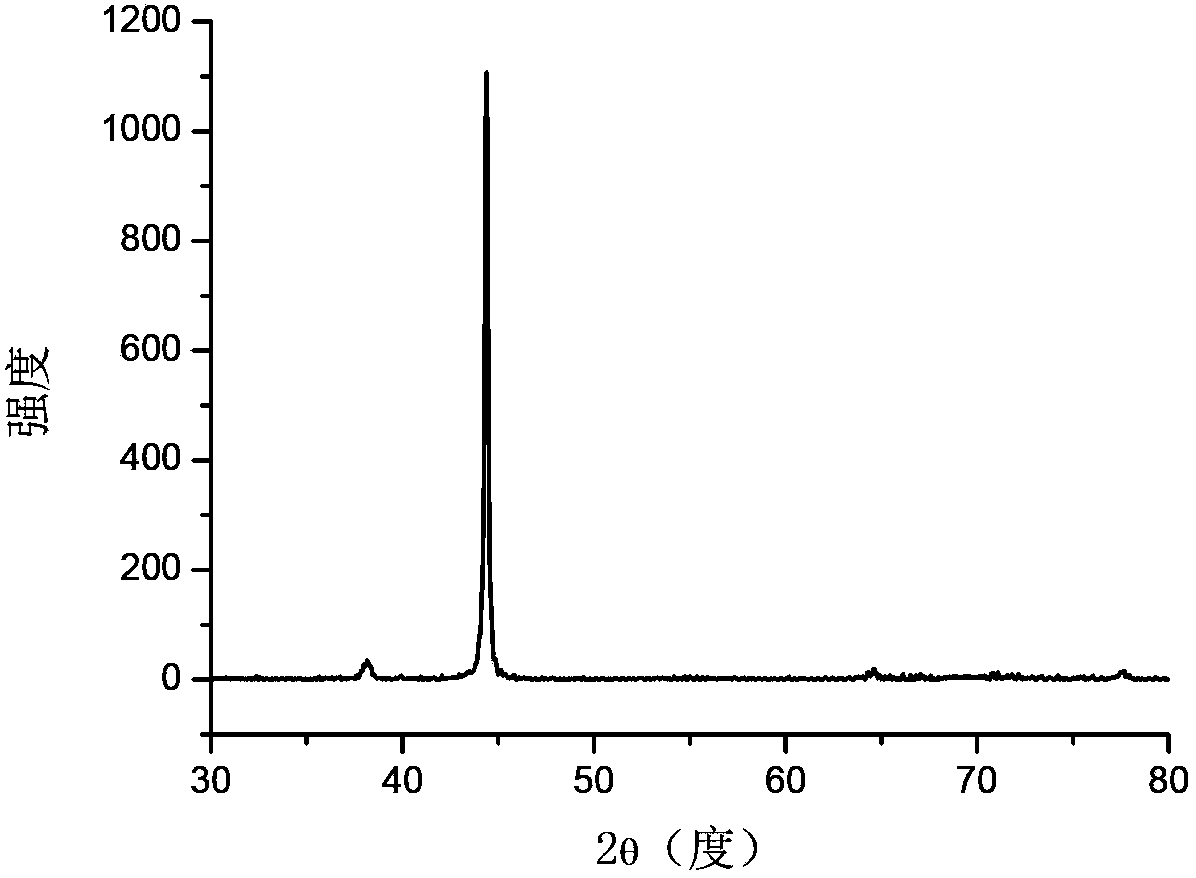

[0017] The preparation method of the vertical array of gold nanorods according to the present invention comprises:

[0018] 1) Prepare an aqueous solution of trimethylcetylammonium bromide-modified gold nanorods, and redissolve them by centrifugation so that the concentration of trimethylcetylammonium bromide in the aqueous solution is 5-20umol / L, and the concentration of gold nanorods is 0.5-2nmol / L;

[0019] 2) contacting the mixture of monoalcohol with 1-3 carbon atoms and alkyl mercaptan with 9-12 carbon atoms with the aqueous solution obtained in step 1);

[0020] 3) After mixing chloroform and / or dichloroethane with the mixture obtained in step 2), and standing still, a vertical array of gold nanorods is obtained.

[0021] According to the present invention, the method for preparing the aqueous solution of gold nanorods modified by trimethylhexadecylammonium bromide can be carried out by using conventional methods in the art. For example, it can be prepared by seed gr...

Embodiment 1

[0045] 1) Take 1 mL of the aqueous solution of gold nanorods modified by trimethylhexadecylammonium bromide (the concentration of trimethylcetylammonium bromide is 0.1mol / L, and the concentration of gold nanorods is 1nmol / L) , after centrifuging at a speed of 12000rpm / min in a desktop high-speed centrifuge for 4 minutes, separate the precipitate, then fully dissolve the precipitate with 1mL of water, and then centrifuge under the same conditions, dissolve the precipitate with 1mL of water to obtain trimethyl The concentration of cetyl ammonium bromide is 10umol / L, and the concentration of gold nanorods is 1nmol / L in aqueous solution.

[0046] 2) Add 1mL of the aqueous solution obtained in step 1) into a 10mL glass bottle at a temperature of 25°C and a stirring speed of 700rpm / min, and drop in the mixture of ethanol and undecylmercaptan (The volume ratio of ethanol and undecyl mercaptan is 50:15) 65uL, continue to stir for 3min; then at the same temperature, change the stirring...

Embodiment 2

[0051] 1) Take 2 mL of an aqueous solution of gold nanorods modified by trimethylhexadecylammonium bromide (the concentration of trimethylcetylammonium bromide is 0.1mol / L, and the concentration of gold nanorods is 1.2nmol / L ), centrifuged at a speed of 12000rpm / min in a desktop high-speed centrifuge for 4 minutes, separated the precipitate, then fully dissolved the precipitate with 2mL of water, and then centrifuged under the same conditions, dissolved the precipitate with 2mL of water to obtain three The concentration of methyl cetyl ammonium bromide is 13umol / L, and the concentration of gold nanorods is 1.5nmol / L in aqueous solution.

[0052] 2) At a temperature of 25°C and a stirring speed of 900rpm / min, add 2mL of the aqueous solution obtained in step 1) into a 10mL glass bottle, and mix the mixture of ethanol and dodecylmercaptan (ethanol The volume ratio to dodecyl mercaptan is 80:20) 200uL is added twice, the same amount is added each time, and stirred for 2 minutes af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com