Cobaltosic oxide array/titanium mesh water decomposition oxygen production electrode and preparation method thereof

A nano-technology of cobalt tetroxide and nano-cobalt oxide is applied in the direction of electrodes, electrolysis components, electrolysis process, etc., which can solve the problems of difficult reuse of supporting materials, poor mechanical properties of carbon cloth and carbon paper, and difficult industrial application of materials, etc. Achieve the effects of easy scale-up production, reduced electron transport resistance, good activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

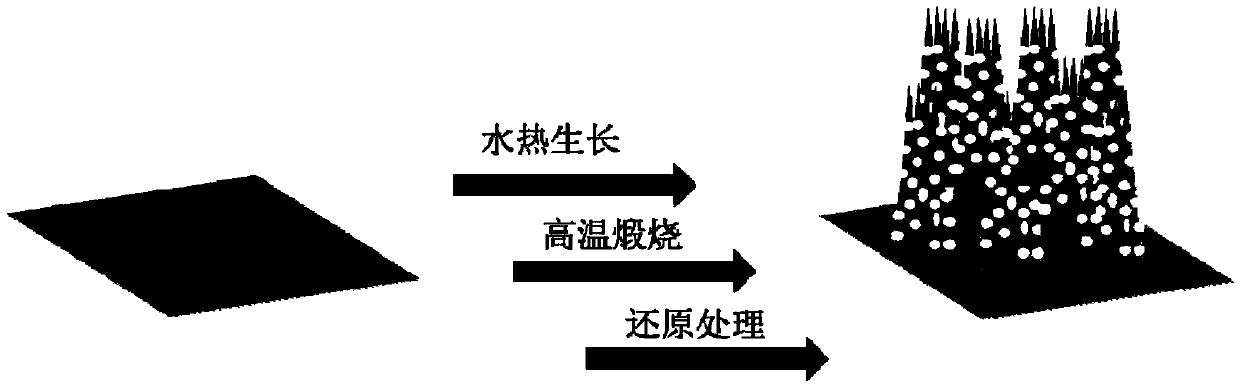

[0019] The preparation method of the cobalt trioxide nanobeam array / titanium mesh electrode of the present invention comprises the following process steps:

[0020] Use cobalt salt, ammonium fluoride and urea as raw materials, add water as a reaction solvent, mix evenly and add titanium mesh into the hydrothermal reaction kettle, control the hydrothermal reaction temperature range 90-200 ° C, time 1-50 Hours, high-temperature calcination temperature of 300-500 DEG C, reduction treatment time of 5-60 minutes in a reducing agent, to obtain tricobalt tetraoxide nanobeam array / titanium mesh composite oxygen production electrode.

[0021] Wherein the cobalt salt is selected from cobalt chloride, cobalt bromide, cobalt fluoride, cobalt acetate, cobalt nitrate, cobalt sulfate and cobalt carbonate. Ammonium fluoride acts as a structure-directing agent in the hydrothermal reaction, and urea is hydrolyzed in the reaction to produce CO 3 2- and OH - , to promote the formation of cobal...

Embodiment 1

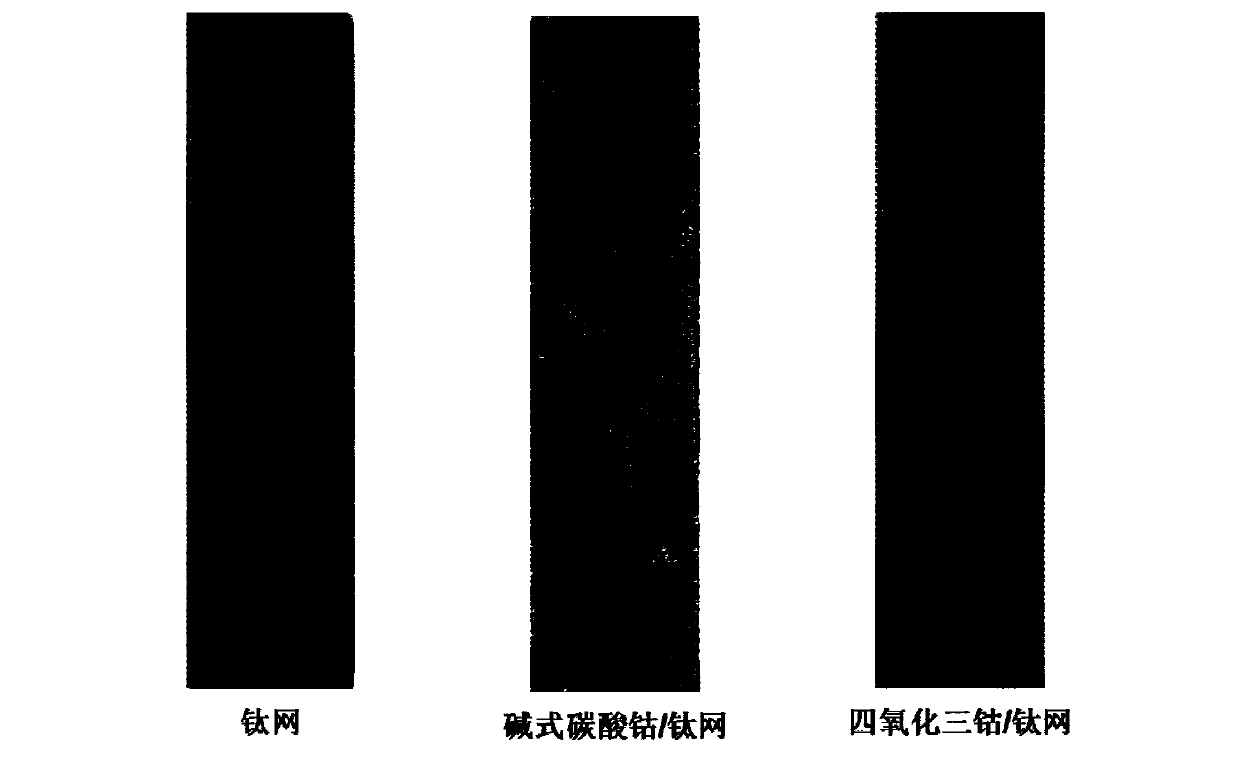

[0029] The molar weight is respectively the cobalt chloride of 1.5mmol, 7.5mmol, 4mmol, the mixed precursor of urea, ammonium fluoride and 25mL deionized water is placed in 50 milliliters of reaction kettles, and the titanium mesh ( 80 mesh) was placed in the kettle, and the reaction kettle was heated to 120°C in an oven, reacted for 4 hours, and finally cooled naturally to obtain a basic cobalt carbonate / titanium mesh electrode. Put the basic cobalt carbonate / titanium mesh electrode in a muffle furnace at 350°C, react for 2 hours, soak the calcined electrode in a hydrazine hydrate solution (aqueous solution, the same below, the concentration is 80wt%) for 20 minutes, wash and dry to obtain tricobalt tetroxide Nanobeam array / titanium mesh oxygen generation electrode.

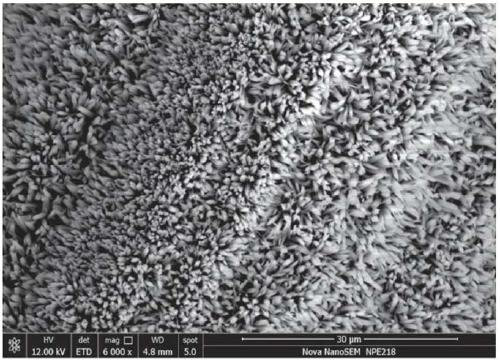

[0030] The growth amount of the obtained cobalt trioxide nanobeam array is 0.843mg / cm 2 Titanium mesh, and the length of the cobalt tetraoxide nano-beam array is 4-5 μm, and the nano-beam size (average diameter) ...

Embodiment 2

[0032] The molar weight is respectively the cobalt chloride of 1.5mmol, 7.5mmol, 4mmol, the mixed precursor of urea, ammonium fluoride and 25mL deionized water is placed in 50 milliliters of reaction kettles, and the titanium mesh ( 80 mesh) was placed in the kettle, and the reaction kettle was heated to 120°C in an oven, reacted for 4 hours, and finally cooled naturally to obtain a basic cobalt carbonate / titanium mesh electrode. Place the basic cobalt carbonate / titanium mesh electrode in a muffle furnace at 350°C, react for 2 hours, soak the calcined electrode in hydrazine hydrate solution (80wt%) for 10 minutes, wash and dry to obtain cobalt trioxide nanobeam array / titanium mesh oxygen electrode.

[0033] The growth amount of the obtained cobalt trioxide nanobeam array is 0.843mg / cm 2 Titanium mesh, and the length of the cobalt tetraoxide nanobeam array is 4-5 μm and the size of the nanobeam is 300nm as observed by the microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com