Preparation method and application of grafted dendritic polymer electrostatic spinning nanofiber membrane oil-water separation material

A nanofiber membrane and electrospinning technology, which is applied in the field of preparation of grafted dendritic polymer electrospinning nanofiber membrane oil-water separation materials, can solve problems such as unfounded construction ideas, and achieve improved oil-water separation efficiency and excellent performance. Structural properties, effects of increasing crash efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

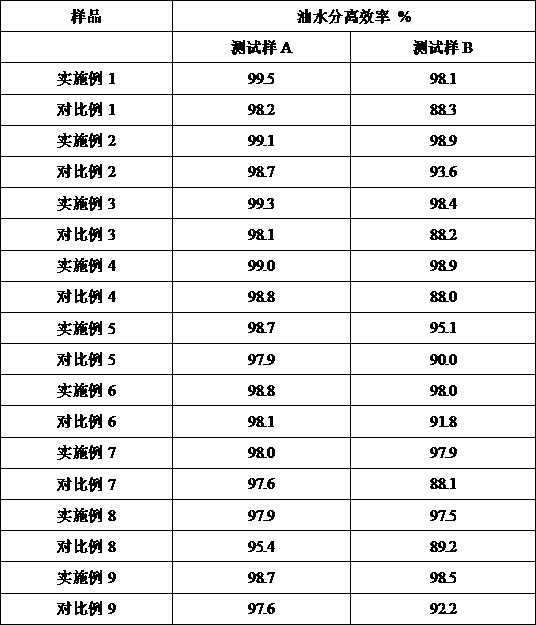

Embodiment 1

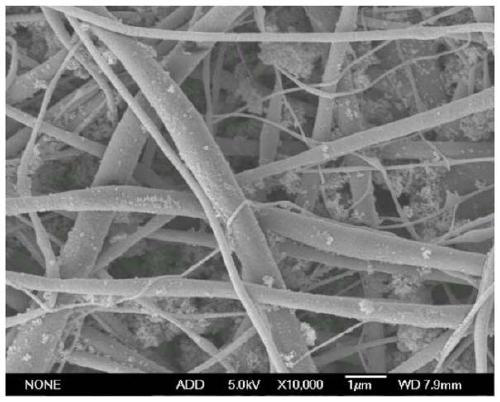

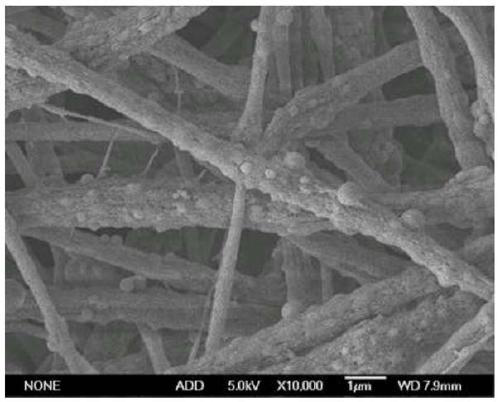

[0025] Electrospun nanofibrous membranes were prepared from polyacrylonitrile. The dendritic polymer PAMAM (G1) is used as the dendritic polymer, which is modified by silane coupling agent γ-aminopropyltrimethoxysilane. Subsequently, the nano-silica is used as inorganic nanoparticles, modified by ethanolamine, and the modified nano-silica is grafted onto the oil-water separation membrane.

[0026] Under the protection of nitrogen, add 2.5 g of dendritic polymer PAMAM (G1) into the three-necked flask, raise the temperature to 180 °C, and then add 10 g of silane coupling agent γ-aminopropyltrimethoxy to the Erlenmeyer flask Silane, and mixed evenly, reacted at this temperature for 6 hours, stopped the reaction and condensed to obtain PAMAM modified by silane coupling agent. The modified dendritic polymer is reacted with the nanofiber membrane coated with polydopamine on the surface to obtain the modified nanofiber membrane.

[0027] Using nano-silicon dioxide as nanoparticles ...

Embodiment 2

[0030] Electrospun nanofibrous membranes were prepared from polyacrylonitrile. Using the dendritic polymer PAMAM (G1) as the dendritic polymer, the modified nanofibrous membrane was obtained by modifying the silane coupling agent N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane , and subsequently, using nano-silica as inorganic nanoparticles, modified by propanolamine, and the modified nano-silica is grafted onto the oil-water separation membrane.

[0031] Under the protection of nitrogen, add 3 g of dendritic polymer PAMAM (G1) into the three-necked flask, raise the temperature to 160 °C, and then add 12 g of silane coupling agent N-β-(aminoethyl )-γ-aminopropylmethyldimethoxysilane, and mix uniformly, react at this temperature for 8 hours, stop the reaction and condense to obtain PAMAM modified by silane coupling agent. The modified dendritic polymer is reacted with the nanofiber membrane coated with polydopamine on the surface to obtain the modified nanofiber membrane. ...

Embodiment 3

[0035] Electrospun nanofibrous membranes were prepared from polyacrylonitrile. The dendritic polymer PAMAM (G2) was used as the dendritic polymer and modified by the silane coupling agent γ-aminopropyltrimethoxysilane to obtain a modified nanofibrous membrane, followed by nano-silica as the inorganic nanoparticle , modified by propanolamine, the modified nano-silica is grafted onto the oil-water separation membrane.

[0036] Under the protection of nitrogen, add 2g of dendritic polymer PAMAM (G2) into the three-necked flask, raise the temperature to 200°C, then add 10g of silane coupling agent γ-aminopropyltrimethoxysilane into the Erlenmeyer flask, And mix evenly, react at this temperature for 6 hours, stop the reaction and condense to obtain PAMAM modified by silane coupling agent. The modified dendritic polymer is reacted with the nanofiber membrane coated with polydopamine on the surface to obtain the modified nanofiber membrane.

[0037] Using nano-silicon dioxide as na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com