Preparation method of high-oil-absorption and biodegradable lignin-based microporous molecular sieve

A microporous molecular sieve and biodegradation technology, which is applied in the field of preparation of biodegradable lignin-based microporous molecular sieves with high oil absorption rate, can solve the problem of low primary oil absorption rate, water absorption, oil absorption performance interference, low three-dimensional network chemical cross-linking structure and other problems, to achieve the effect of uncomplicated treatment method, wide application range and simple recovery treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

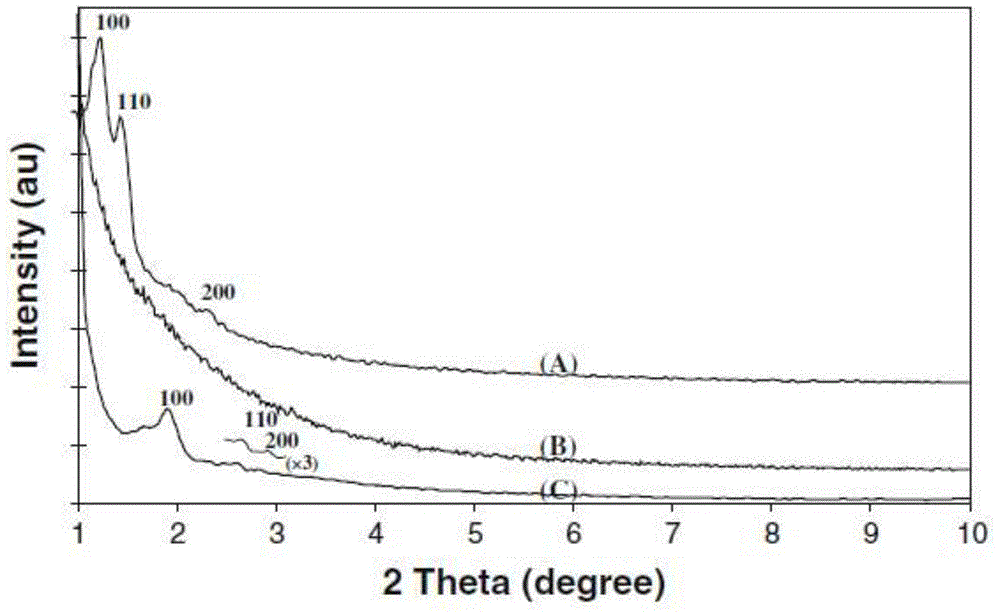

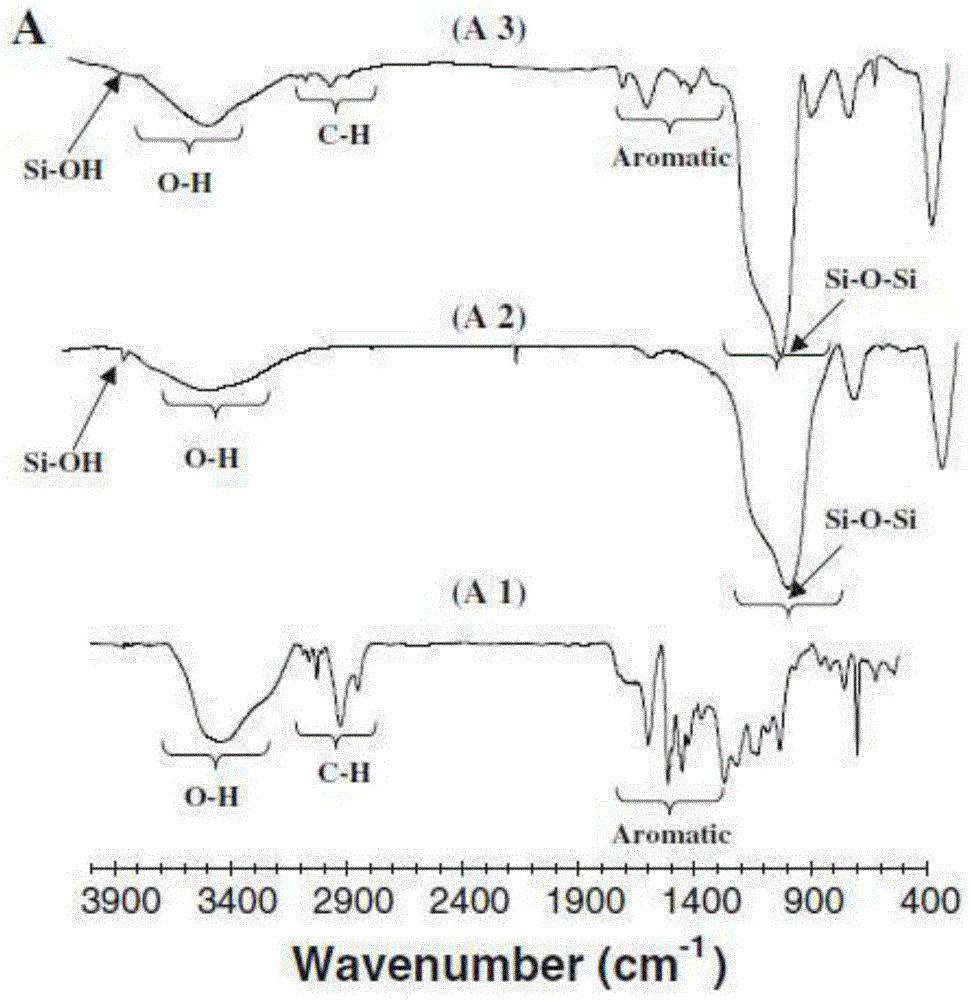

[0033] Under the condition of a reaction temperature of 90° C., 1 g of lignin was dissolved in 50 g of pyridine / dioxane mixture (pyridine:dioxane=1:10, mass ratio), and an appropriate amount of acetic anhydride reagent (acetic anhydride and The molar ratio of the hydroxyl groups in the lignin is 1:2), and the stirring is continued to cause the acetylation reaction between the hydroxyl groups in the lignin and acetic anhydride, and the reaction time is 2 hours. After the product is cooled to room temperature, it is filtered, washed with water three times, and dried to obtain acetyl lignin. At a reaction temperature of 70°C, dissolve acetyl lignin in a mixture of pyridine / triethoxychlorosilane (pyridine:triethoxychlorosilane=1:5, mass ratio), in which triethoxychlorosilane The molar ratio to the hydroxyl group in acetyl lignin is 1:1. Stirring is continued to make the hydroxyl group in the acetyl lignin react with triethoxychlorosilane, and the reaction time is 12 hours. After...

Embodiment 2

[0036] Refer to Example 1 to prepare acetyl lignin, and then dissolve acetyl lignin in pyridine / triethoxychlorosilane mixture (pyridine:triethoxychlorosilane=1:10) at a reaction temperature of 70°C, wherein The molar ratio of triethoxychlorosilane to hydroxyl in acetyl lignin is 1:1. Continue stirring to make the hydroxyl group in the acetyl lignin react with triethoxychlorosilane, and the reaction time is 10 hours. After the product is cooled to room temperature, it is filtered, washed with water three times and dried to obtain silyl acetyl lignin. Add silyl acetyl lignin to 4A microporous molecular sieve suspension (mass concentration 10%) dissolved in N,N-dimethylformamide (DMF) at room temperature, wherein the molecular sieve hydroxyl group and silyl acetyl lignin The molar ratio of ethoxy groups in the medium is 1:1. N 2 Under protection, the temperature was raised to 150° C., stirred and refluxed for 36 hours. After the product was cooled to room temperature, it was f...

Embodiment 3

[0039] Refer to Example 1 to prepare acetyl lignin, and then dissolve acetyl lignin in pyridine / triethoxychlorosilane mixture (pyridine:triethoxychlorosilane=1:3) at a reaction temperature of 70°C, wherein The molar ratio of triethoxychlorosilane to hydroxyl in acetyl lignin is 1:1. Stirring is continued to make the hydroxyl group in the acetyl lignin react with triethoxychlorosilane, and the reaction time is 12 hours. After the product is cooled to room temperature, it is filtered, washed with water three times and dried to obtain silyl acetyl lignin. Add silyl acetyl lignin to 5A type microporous molecular sieve suspension (mass concentration 5%) dissolved in xylene at normal temperature, wherein the molar ratio of the hydroxyl group in the molecular sieve to the ethoxy group in the silyl acetyl lignin is 1: 1. N 2 Under protection, the temperature was raised to 140° C. and the reaction was stirred and refluxed for 24 hours. After the product was cooled to room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com