Oil pump for automatic transmission with double clutches

An automatic transmission, dual clutch technology, applied in the direction of engine lubrication, lubrication pump, transmission, etc., can solve the problems of increasing the axial length of the transmission, difficult processing, low volumetric efficiency, etc., to improve oil absorption efficiency, improve Longevity, life-span improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

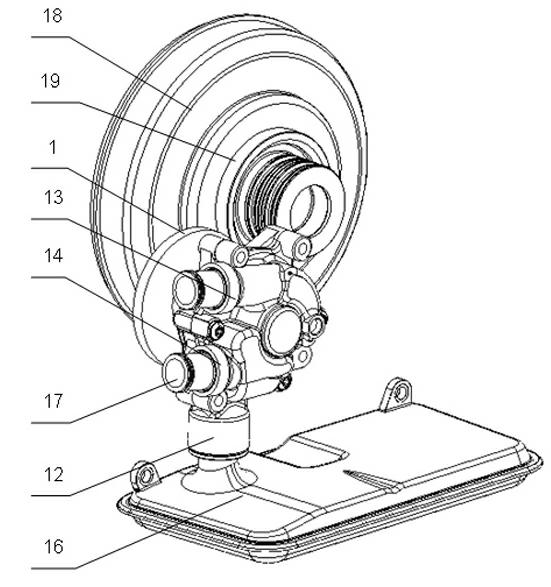

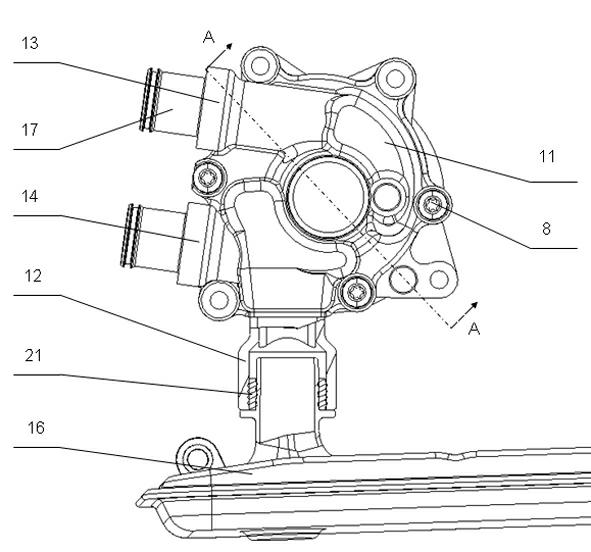

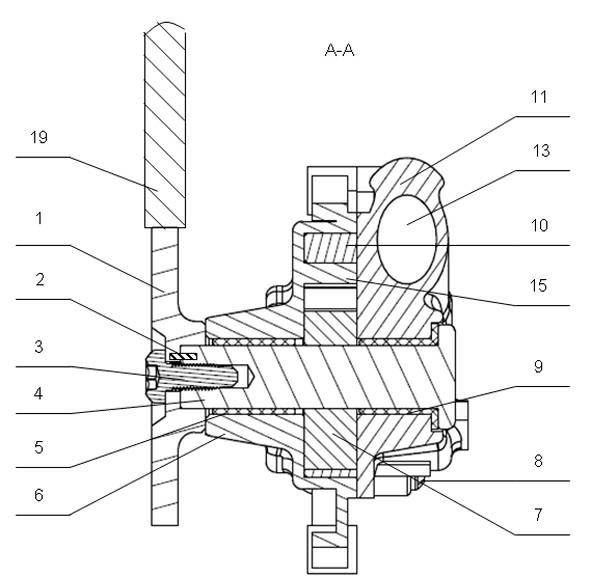

[0027] see figure 1 and image 3 , the oil pump used for dual-clutch automatic transmission includes a front housing 6, an oil pump rear cover 11, a drive shaft 4, an inner rotor gear 7 and an outer rotor ring gear 10, and the outer rotor ring gear 10 is embedded in the front housing 6; The number of teeth of the inner rotor gear 7 is 9, the number of teeth of the outer rotor ring gear 10 is 11, and the difference between the two is 2. The drive shaft 4 runs through the front housing 6 and the oil pump rear cover 11, and one end of the drive shaft 4 is provided with a boss, which is matched with the oil pump rear cover 11, and the other end is the power input end; the inner rotor gear 7 is set on the drive The middle part of the shaft 4, and fits in the outer rotor ring gear 10. The oil pump rear cover 11 is provided with an oil outlet 13 and an oil return port 14, and the bottom of the front housing 6 is provided with an oil suction port 12, and a lip seal ring 21 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com