Concentrated wax removing solution convenient for wax separation, and preparation method thereof

A technology for wax separation and dewaxing water, applied in chemical instruments and methods, non-ionic surface active compounds, detergent compounding agents, etc. Treatment steps, convenient fishing, and the effect of improving oil absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: a kind of concentrated dewaxing water that is convenient to wax separation, each component and its corresponding weight parts are as shown in Table 1, wherein, the trade mark of nonylphenol polyoxyethylene ether is TX-10, coconut oil The grade of fatty acid diethanolamide is 6501, the grade of glycerin is 56-81-5, and the grade of polyethylene glycol is PEG 600;

[0053] Modified MOFs include MOFs and expanded graphite located in its pores. The MOFs in this embodiment are ZIF-14 purchased from Shanghai Kaishu Chemical Technology Co., Ltd. with a product number of MM3730670-1g; the expanded graphite in this embodiment is purchased from Expanded graphite from Qingdao Ouer Graphite Co., Ltd.

[0054] The preparation of modified MOFs includes the following steps:

[0055] Step 1: Grinding the expanded graphite for 50 minutes under a pressure of 0.04Mpa to obtain expanded graphite with a particle size smaller than the pore diameter of MOFs;

[0056] Step 2: A...

Embodiment 2-4

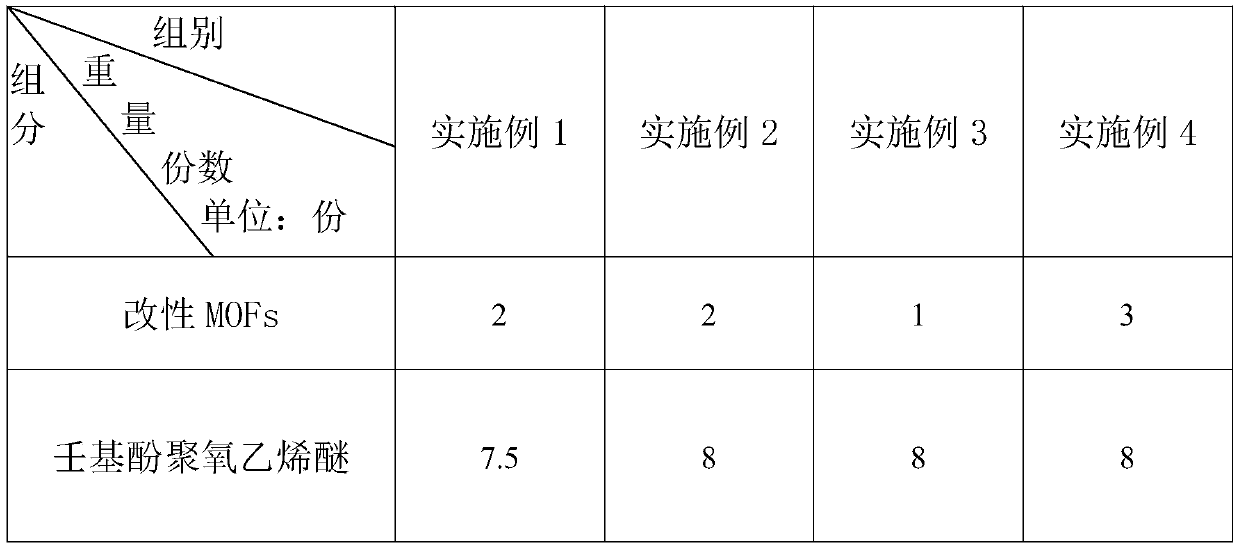

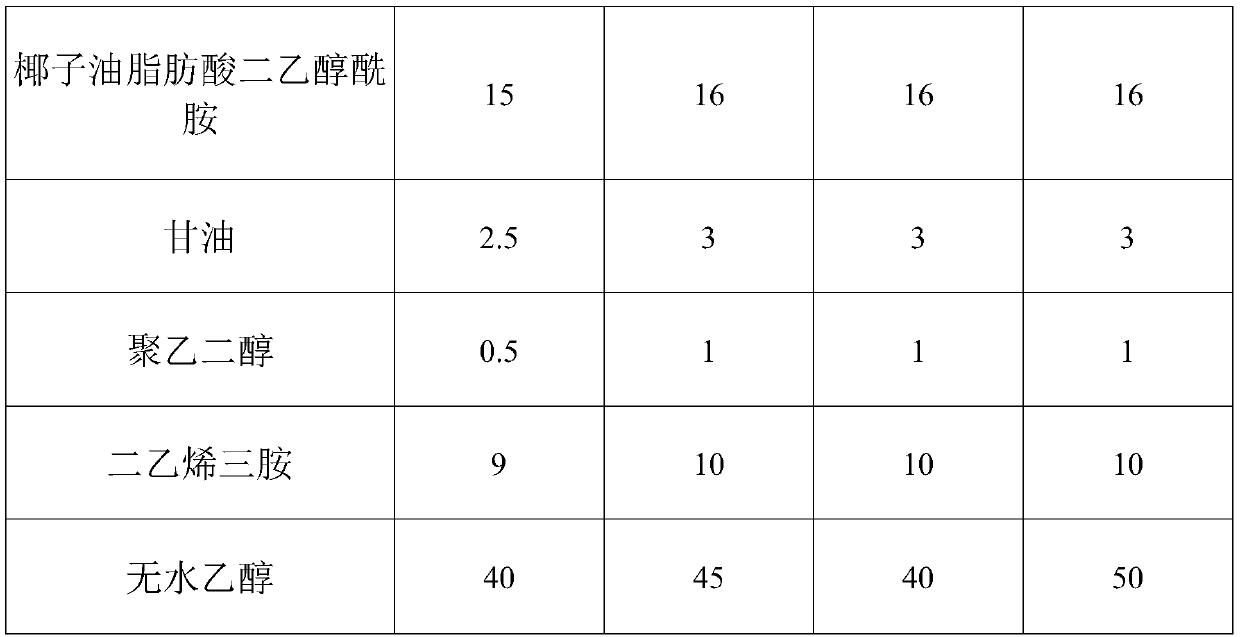

[0063] Example 2-4: A concentrated wax-removing water that is convenient for wax separation. The difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0064] Each component and parts by weight thereof in table 1 embodiment 1-4

[0065]

[0066]

Embodiment 5

[0067] Example 5: A concentrated wax-removing water that is convenient for wax separation. The difference from Example 1 is that the MOFs mixed solution is subjected to ultrasonic treatment before centrifugal drying. The frequency of ultrasonic treatment is 25kHz and the time is 20min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion amount | aaaaa | aaaaa |

| corrosion amount | aaaaa | aaaaa |

| corrosion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com