Recyclable nano fiber oil-absorbing material

A nanofiber, oil-absorbing material technology, applied in the petroleum industry, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of operator injury, low recovery efficiency, etc., to achieve simple operation, easy recovery and reuse, avoid direct contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

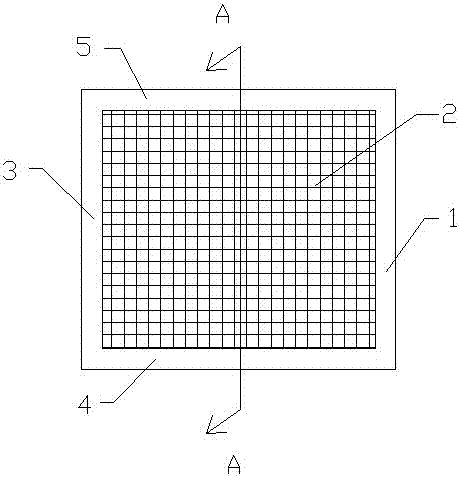

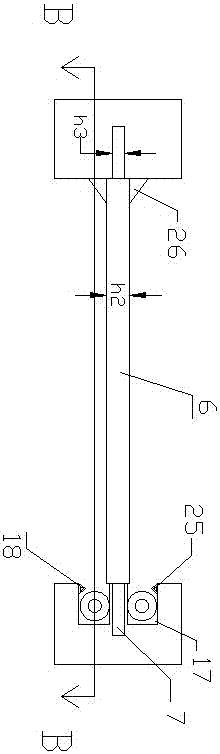

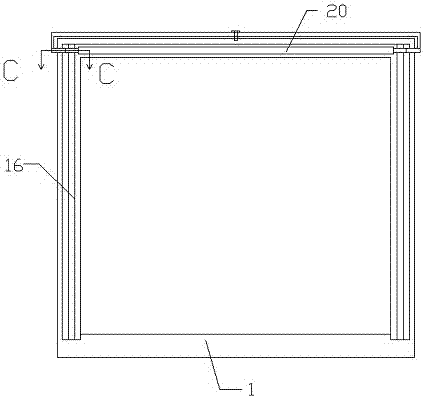

[0030] As shown in the figure, a recyclable nanofiber oil-absorbing material includes a fixing mechanism 1 and an oil-absorbing felt 2. The fixing mechanism includes a fixing frame and an extrusion mechanism. The fixing frame includes two side frames 3, a front frame 4 and A rear frame 5, two side frames are arranged parallel to each other, the front frame and the rear frame are respectively vertically fixed on the front and rear ends of the two side frames, the oil-absorbing felt includes a felt body 6 and a side strip 7, and the side strips are fixed on the fixed between frames;

[0031] The felt body consists of the first gauze layer 8, the first nanofiber layer 9, the second gauze layer 10, the second nanofiber layer 11, the third gauze layer 12, the first nanofiber layer and the first gauze layer from top to bottom. Gauze laminated synthesis; the first nanofiber layer is composed of nanofibers with a diameter of 30-50nm, the second nanofiber layer is composed of nanofiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com