A kind of stainless steel fiber felt used for fuel cell bipolar plate and its manufacturing method

A fuel cell and manufacturing method technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of commercialization of fuel cells, complex processing technology, poor thermal conductivity that affect fuel cell performance, and achieve good heat and mass transfer performance. , the production process is simple and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The present invention is used for the stainless steel fiber felt of fuel cell bipolar plate, can adopt following method to realize:

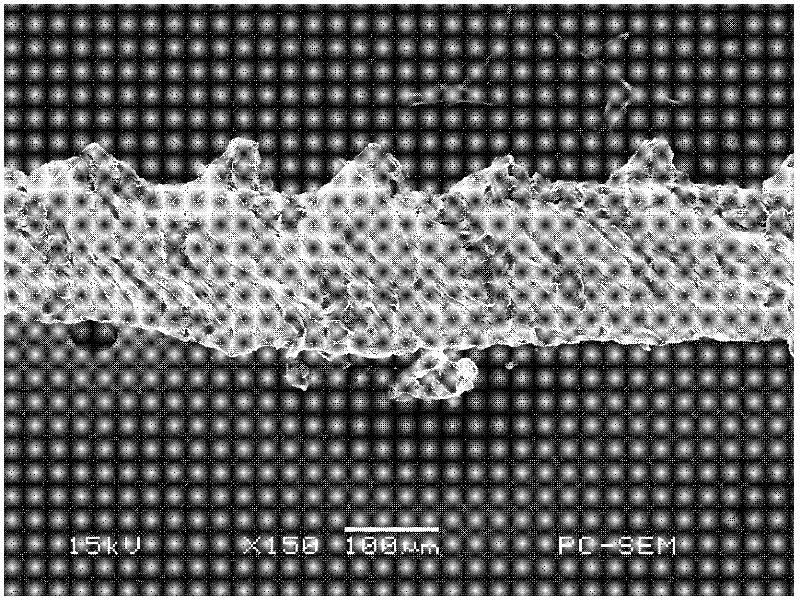

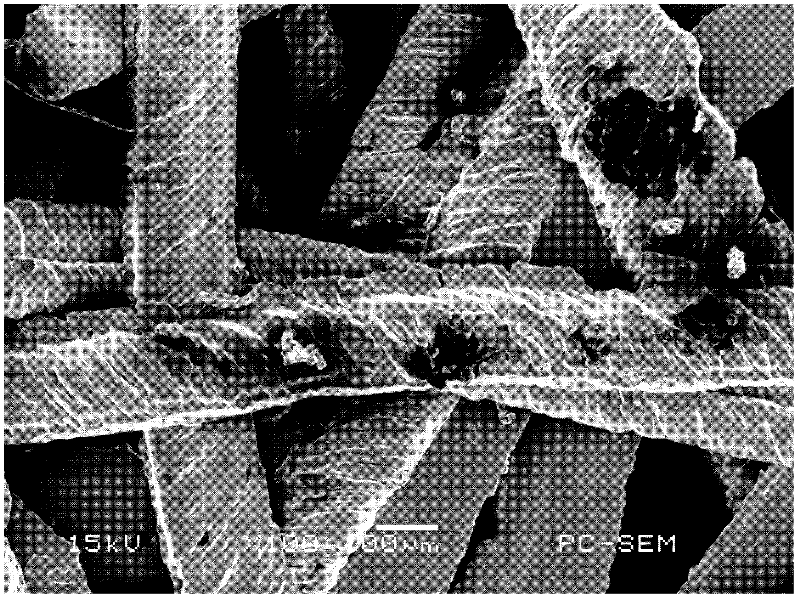

[0030] The first step is cutting method to process stainless steel fiber. First, clean and degrease the surface of the stainless steel round rod workpiece, then clamp the stainless steel rod on a CM6140 lathe, and remove the surface oxide layer by turning. The stainless steel fiber is cut and processed on the lathe by using a multi-tooth tool with a large edge inclination. The tool material is made of superhard high-speed steel, and the tool is made by wire cutting. SEM picture of stainless steel fiber figure 1 As shown, the processed stainless steel fibers have a diameter of 50 μm–200 μm, a zigzag structure at the edge, and a rich multi / microscale surface structure on the surface.

[0031] The second step is the pretreatment of stainless steel fibers. Use shearing equipment to cut stainless steel fibers into short stainless steel fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com