Method for preparing aluminosilicate nanotube by using kaolinite raw material

A technology of aluminosilicate and kaolinite, applied in the direction of silicate, aluminum silicate, nanotechnology, etc., can solve the problems of environmental hazards, cumbersome technical methods, and many types of reaction raw materials, and achieve low cost and simple process Ease of operation, tubular shape and high structural uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of kaolinite-dimethyl sulfoxide complex: 10 g of Maoming kaolinite was added to 60 mL of dimethyl sulfoxide, and stirred at 150° C. for 2 days. Then centrifuge at 4000 rpm for 3 minutes for solid-liquid separation. Recover the supernatant for recycling. Dry the obtained solid at 90°C to constant weight to obtain the kaolinite-dimethyl sulfoxide composite.

[0029] 2. Preparation of kaolinite-methanol complex: 5 g of the kaolinite-dimethyl sulfoxide complex obtained in step 1 was added to 50 mL of methanol, and stirred at room temperature for 7 days. Then centrifuge at 4000 rpm for 3 minutes for solid-liquid separation. The resulting solid is the kaolinite-methanol complex.

[0030] 3. Preparation of aluminosilicate nanotubes: Hexadecyltrimethylammonium chloride was dissolved in methanol to prepare a solution with a concentration of 1 mol / L. Add 1.0 g of the kaolinite-methanol complex prepared in step 2 to 40 mL of the above solution, and stir at 60° C...

Embodiment 2

[0034] 1. Preparation of kaolinite-dimethyl sulfoxide complex: 10 g of Maoming kaolinite was added to 60 mL of dimethyl sulfoxide, and stirred at 150° C. for 2 days. Then centrifuge at 4000 rpm for 3 minutes for solid-liquid separation. The obtained solid was dried at 90° C. to a constant weight to obtain a kaolinite-dimethyl sulfoxide composite.

[0035] 2. Preparation of kaolinite-methanol complex: 5 g of the kaolinite-dimethyl sulfoxide complex obtained in step 1 was added to 50 mL of methanol, and stirred at room temperature for 7 days. Then centrifuge at 4000 rpm for 3 minutes for solid-liquid separation. The resulting solid is the kaolinite-methanol complex.

[0036] 3. Preparation of aluminosilicate nanotubes: dodecyltrimethylammonium bromide was dissolved in methanol to prepare a solution with a concentration of 1 mol / L. Add 1.0 g of the kaolinite-methanol complex prepared in step 2 to 40 mL of the above solution, and stir at 60° C. for 24 hours. Then centrifuge at...

Embodiment 3

[0039] 1. Preparation of kaolinite-dimethyl sulfoxide complex: 10 g of Maoming kaolinite was added to 60 mL of dimethyl sulfoxide, and stirred at 150° C. for 2 days. Then centrifuge at 4000 rpm for 3 minutes for solid-liquid separation. The obtained solid was dried at 90° C. to a constant weight to obtain a kaolinite-dimethyl sulfoxide complex.

[0040] 2. Preparation of kaolinite-methanol complex: 5 g of the kaolinite-dimethyl sulfoxide complex obtained in step 1 was added to 50 mL of methanol, and stirred at room temperature for 7 days. Then centrifuge at 4000 rpm for 3 minutes for solid-liquid separation. The resulting solid is the kaolinite-methanol complex.

[0041] 3. Preparation of aluminosilicate nanotubes: Hexadecyltrimethylammonium chloride was dissolved in methanol to prepare a solution with a concentration of 1 mol / L. Add 1.0 g of the kaolinite-methanol complex prepared in step 2 to 40 mL of the above solution, and stir at 60° C. for 24 hours. Then centrifuge a...

PUM

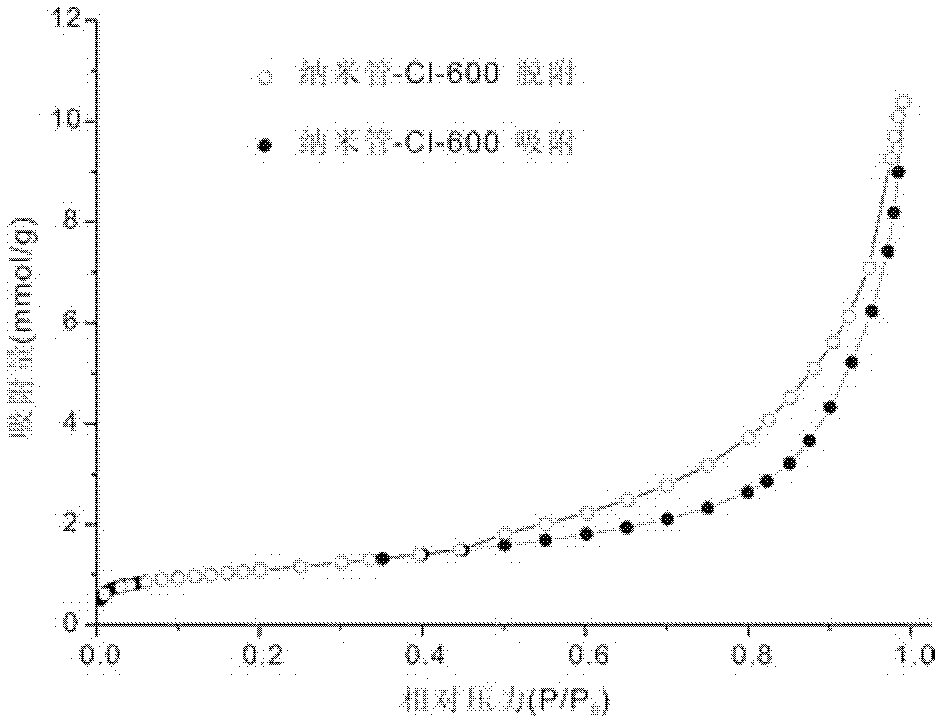

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com