Long-life asphalt pavement structure

An asphalt pavement, long-life technology, applied to roads, roads, on-site coagulation pavement, etc., can solve problems such as poor drainage, reflective cracks, road subsidence, etc., achieve significant anti-fatigue cracking performance, and prolong the service life of roads , to increase the effect of the initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

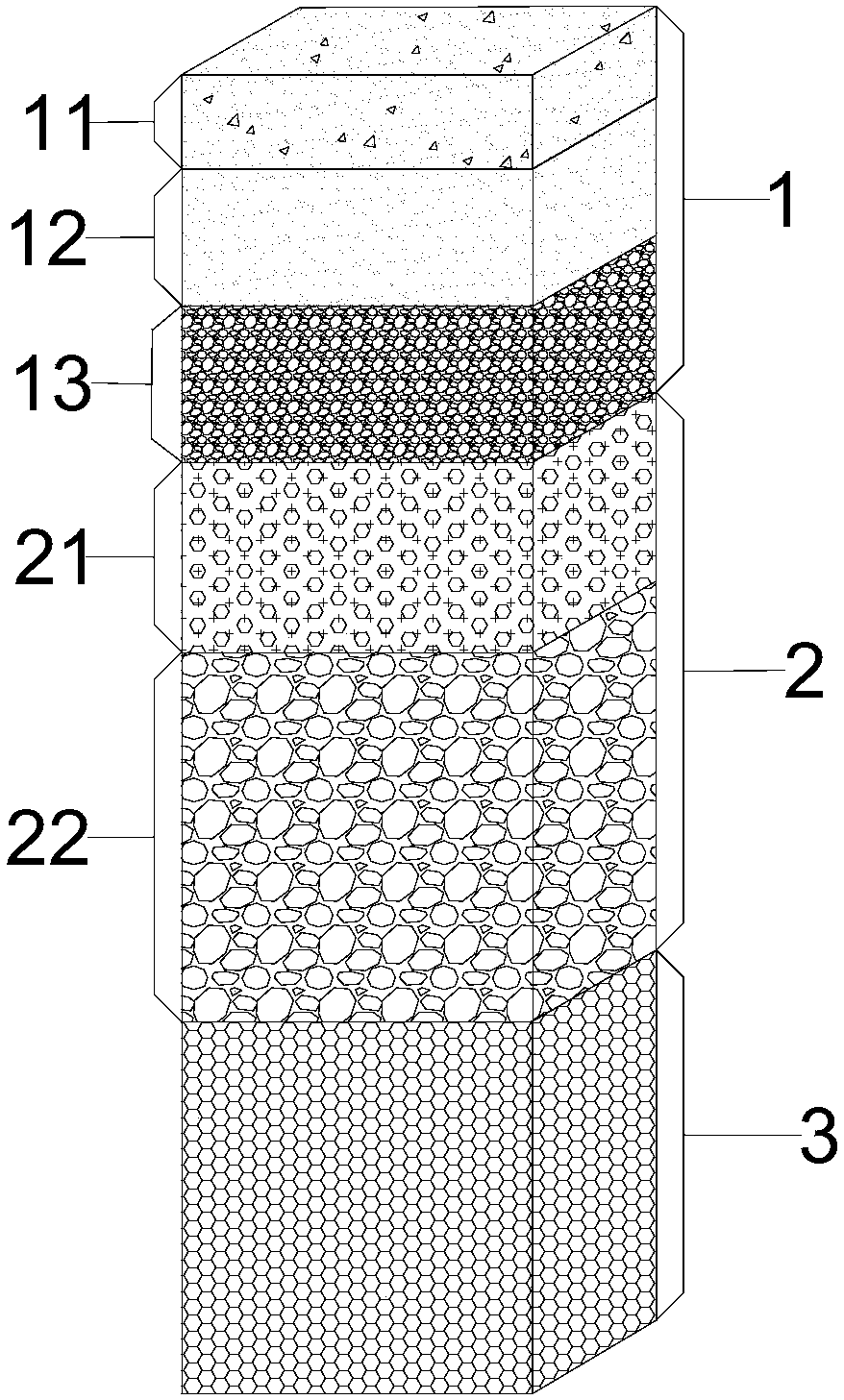

[0036] Such as figure 1 A long-life asphalt pavement structure shown,

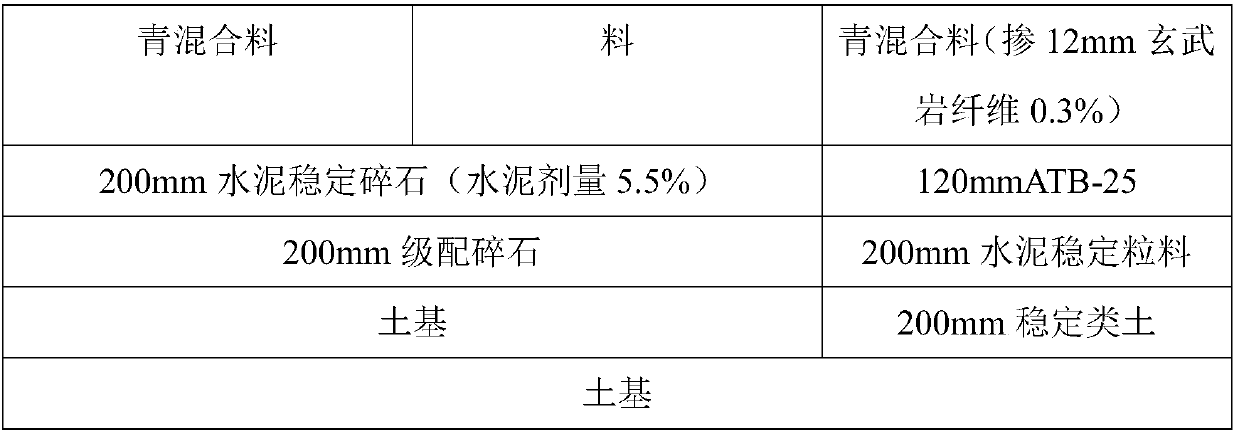

[0037] The asphalt pavement structure includes an asphalt surface layer, a crack-resistant rigid-flexible composite base and a subbase in sequence from top to bottom; the asphalt surface layer includes a surface wear layer, a middle surface layer and an underlayer; the flexible upper base layer is made of asphalt stabilized gravel , the semi-rigid sub-base is cement-stabilized aggregates; the sub-base is stabilized soil.

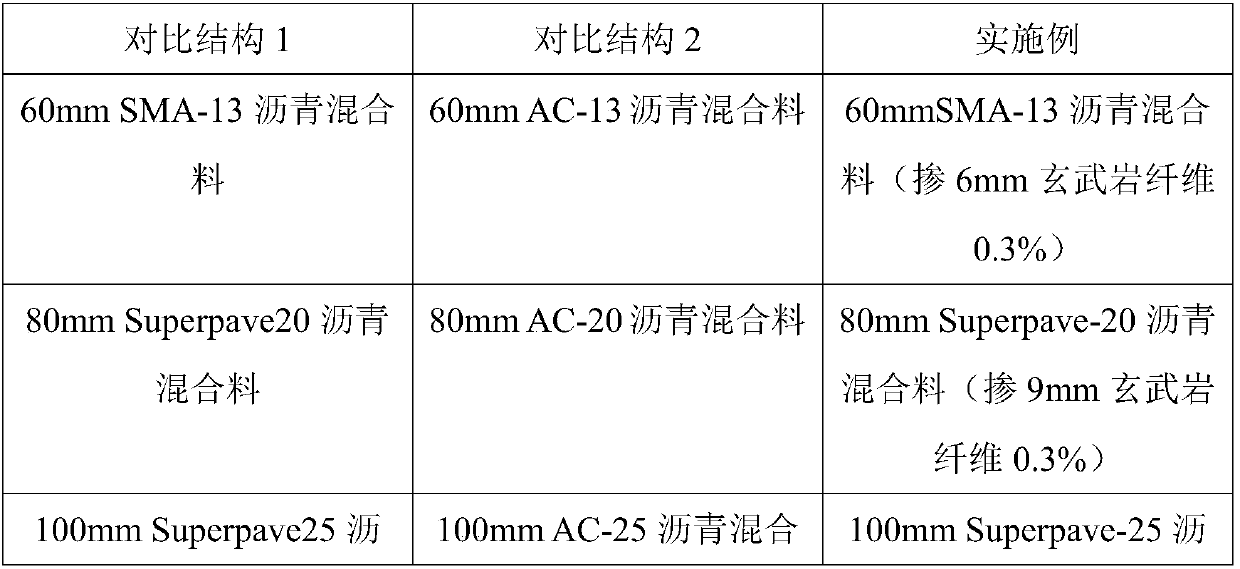

[0038] Among them, the wear layer on the surface adopts SMA-13 graded asphalt mixture, the thickness is 50-70mm, and the material mass ratio is: SBS modified asphalt: the first mineral material: basalt fiber = 5.8-6.0:100:0.3-0.4 , the nominal maximum particle size is 13.2mm.

[0039] Among them, the middle surface layer adopts Superpave-20 graded asphalt mixture, the thickness is 70-100mm, and the material mass ratio is: SBS modified asphalt: the second mineral material: basalt fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com