Construction method for reconstruction of old cement pavement into asphalt concrete pavement

A construction method and technology of old cement, applied in the direction of roads, roads, pavement details, etc., can solve problems such as cracks in the cover layer, reduce maintenance costs, improve the ability to resist reflection cracks and temperature shrinkage cracks, and have no congestion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

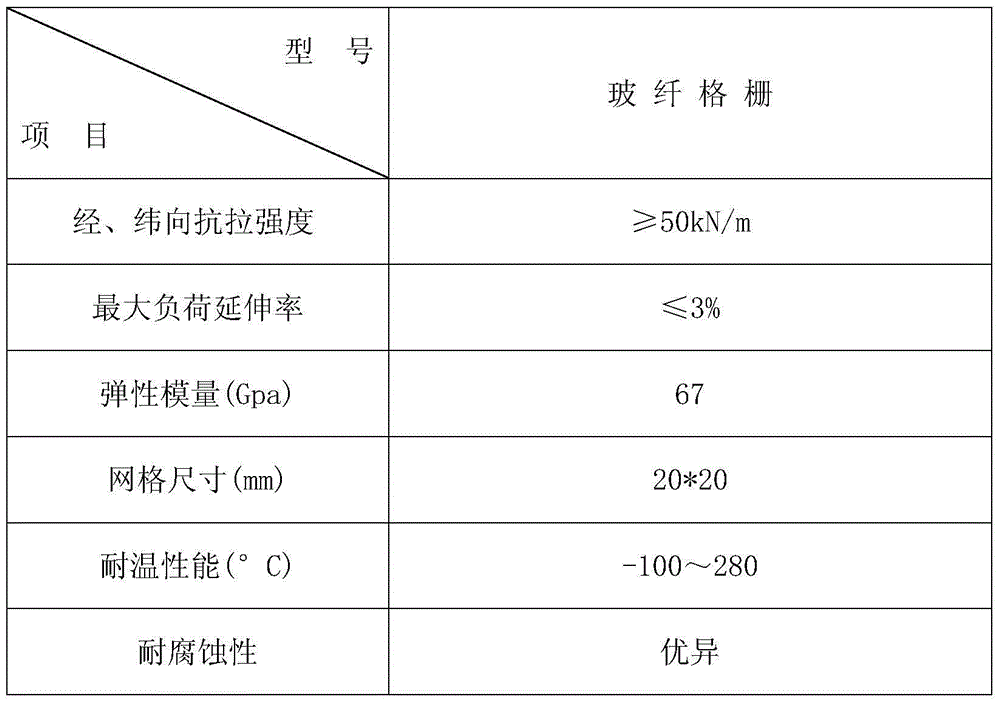

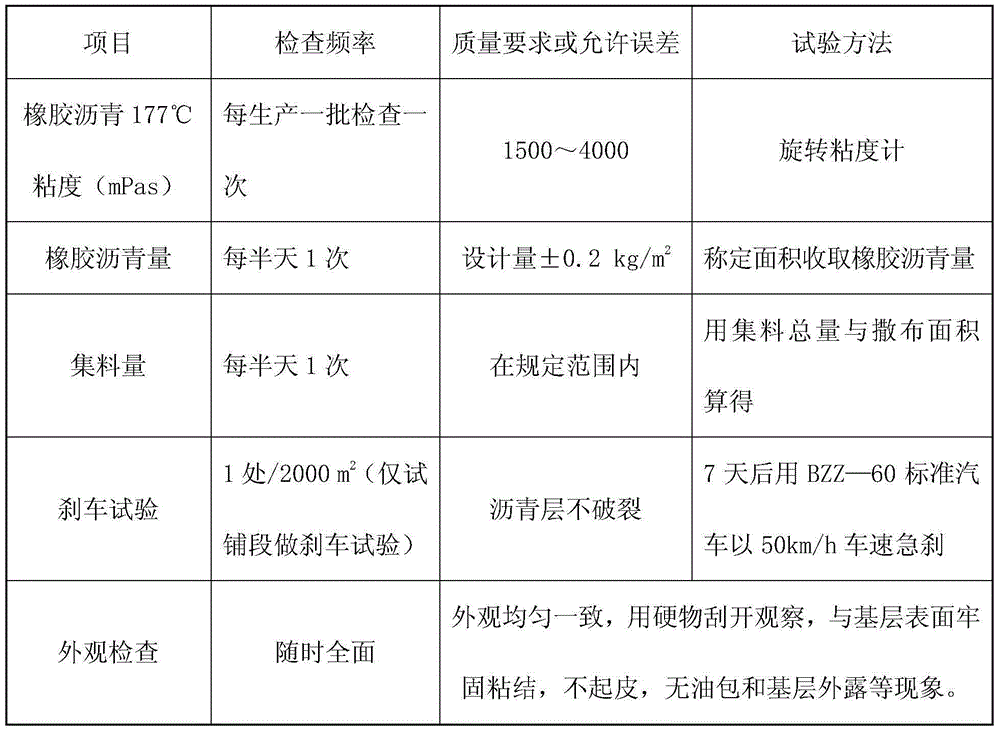

[0033] According to research by domestic and foreign experts, asphalt concrete pavement cracks are mainly caused by reflection cracks caused by the tensile stress generated by the horizontal and vertical over-limit displacement of cement concrete at the base level exceeding the tensile strength of the asphalt concrete overlay, while traffic loads and temperature effects These are the two major factors that cause reflective cracks. Aiming at the causes of these cracks and combined with the successful experience in previous pavement construction, the applicant used the rubber asphalt stress absorbing layer and the glass fiber grid anti-cracking layer in road construction to effectively prevent the "white to black" pavement cracks generation. In order to guide the construction of similar floors, standardize the construction process, unify the quality standard and improve the guarantee measures, the applicant summarized and improved the construction process on the basis of the suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com