A heavy -duty high -life highway structure and construction method

A construction method and life-span technology, applied to roads, roads, on-site coagulation pavements, etc., can solve problems such as insufficient rigidity of the roadbed, and achieve the effects of short construction period, simple structure, and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

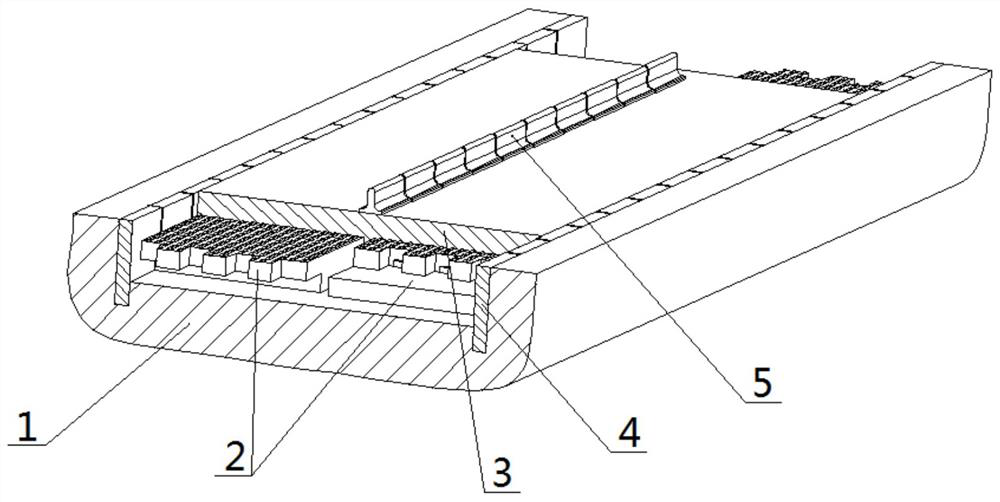

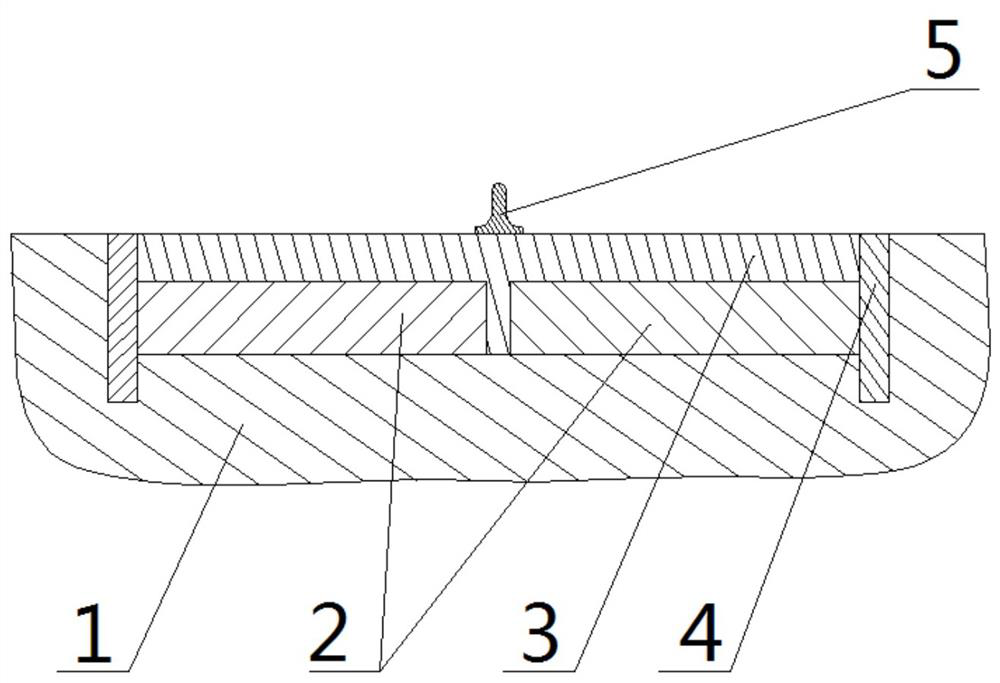

[0041] A heavy-duty and long-life highway structure includes a roadbed 1, a base plate 2, and an asphalt pavement layer 3; the base plate 2 is a prefabricated part, which is produced in a cement product prefabrication factory; The base plate 2 is fixed on the upper part of the roadbed 1; the asphalt pavement layer 3 is laid on the upper part of the base plate 2; the base plate 2 and the asphalt pavement layer 3 are provided with road shoulders 4 on both sides; An isolation pier 5 is arranged in the middle of layer 3;

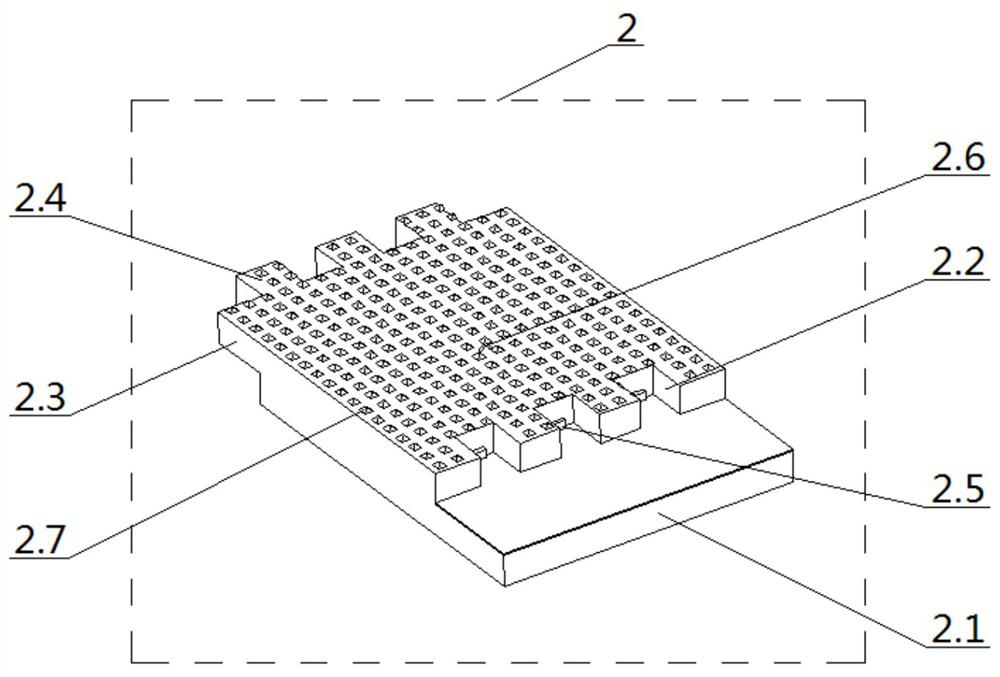

[0042] The base plate 2 is in the shape of a plate, and a lower base plate crimping plate 2.1 is arranged on the lower side of one end portion, and an upper substrate crimping plate 2.3 is arranged on the upper side of the other end portion; 2. The end portion is provided with a substrate docking slot 2.2, and the end portion of the crimping plate 2.3 on the substrate is provided with a substrate docking joint 2.4; the bottom of the substrate docking slot 2.2 is...

Embodiment 2

[0056] A heavy-duty and long-life highway structure includes a roadbed 1, a base plate 2, and an asphalt pavement layer 3; the base plate 2 is a prefabricated part, which is produced in a cement product prefabrication factory; The base plate 2 is fixed on the upper part of the roadbed 1; the asphalt pavement layer 3 is laid on the upper part of the base plate 2; the base plate 2 and the asphalt pavement layer 3 are provided with road shoulders 4 on both sides; An isolation pier 5 is arranged in the middle of layer 3;

[0057] The base plate 2 is in the shape of a plate, and a lower base plate crimping plate 2.1 is arranged on the lower side of one end portion, and an upper substrate crimping plate 2.3 is arranged on the upper side of the other end portion; 2. The end portion is provided with a substrate docking slot 2.2, and the end portion of the crimping plate 2.3 on the substrate is provided with a substrate docking joint 2.4; the bottom of the substrate docking slot 2.2 is...

Embodiment 3

[0071] The upper plate surface array of the substrate 2 is provided with a trapezoidal groove parallel to the running direction of the vehicle, and the lower plate surface array is provided with a substrate anti-displacement bump 2.8; the substrate anti-displacement bump 2.8 is pyramid-shaped and trapezoidal The depth of the groove is smaller than the height of the base plate anti-displacement bump 2.8;

[0072] Finally, it is added that when there is a parallel expansion and contraction joint between the base plate butt joint 2.4 and the base plate butt joint groove 2.2, the thickness of the asphalt pavement layer 3 should be greater than 200mm to avoid the change of the expansion and contraction joint width on the upper asphalt pavement layer. 2.4 When there is a V-shaped stress relief groove 7 between the docking groove 2.2 and the base plate, the aspect ratio of the V-shaped stress relief groove 7 should be reasonably set according to experience, so as to avoid the occurren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com