Deck penetration piece for ship pipe and penetration method

A technology for passing cabin parts and decks, which is applied in the direction of passing components, pipes/pipe joints/pipe fittings, pipes, etc., which can solve the problem of non-perpendicularity between pipeline connectors and pipelines, uneven gap between web and deck, and difficulty in ensuring welding quality and other problems, to achieve the effect of simple structure, low cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

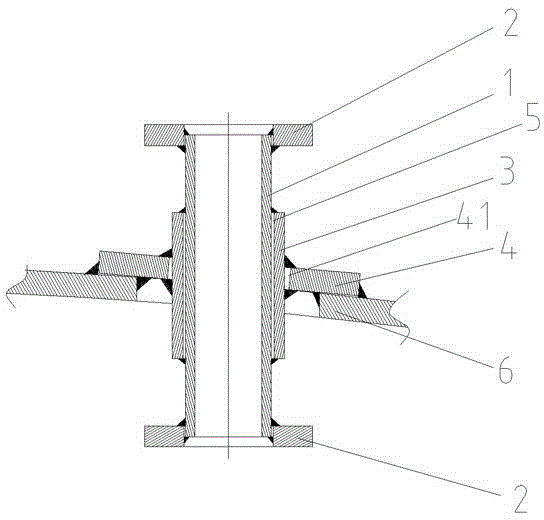

[0025] Such as figure 1 As shown, the deck pass-through part of the present invention comprises a pass-through steel pipe 1, flanges 2 at both ends welded to the pass-through steel pipe 1, sleeve pipe 3, and web 4 respectively, and the sleeve pipe 3 is set on the pass-through steel pipe 1. Both ends are welded in the middle of the steel pipe 1 through the cabin, and the web 4 is loosely sleeved on the casing 3 . The overall galvanization of the deck tank in this embodiment can improve its ability to resist seawater corrosion. Since the diameter of the casing is 2-3 mm larger than the outer diameter of the steel pipe 1, a cylindrical air insulation layer 5 with a uniform thickness of 1-1.5 mm is left between the casing 3 and the steel pipe 1, which can reduce the number of casings 3. When welding with the web 4, the welding heat conducted from the casing 3 to the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com