Electric melting pipe fitting with barrier function and manufacturing method thereof

An electrofusion pipe fitting and function technology, applied in the direction of pipes/pipe joints/pipe fittings, household appliances, tubular objects, etc., can solve the problems that the connection cannot play a barrier function and the barrier type non-metal composite pipe is not well connected, etc. Improve the firmness and compressive ability, suitable for promotion, convenient connection and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

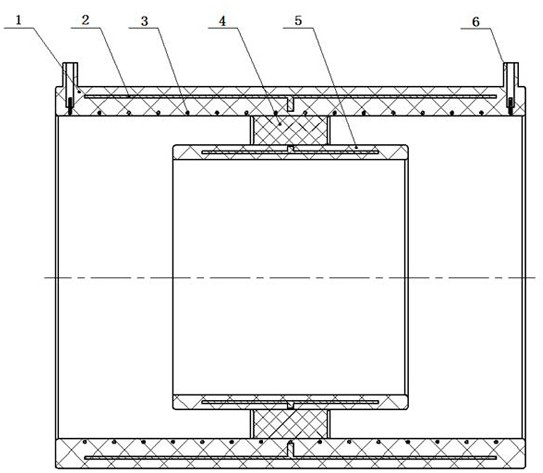

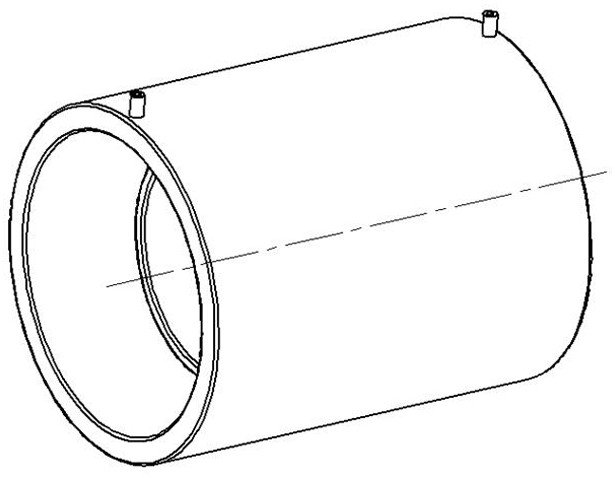

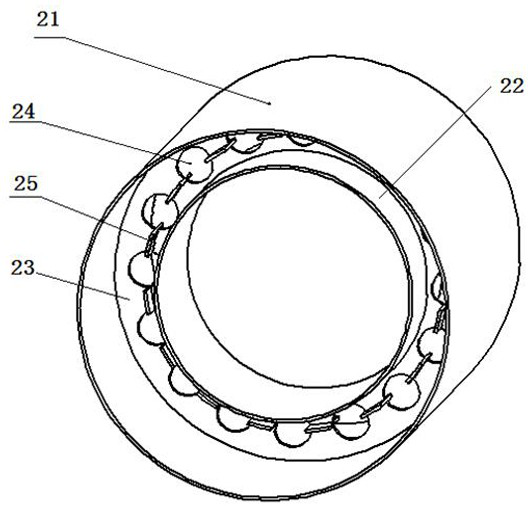

[0031] Such as figure 1 As shown, an electrofusion pipe fitting with a barrier function includes a pipe fitting body, a copper insert 2, a copper wire 3, an EVOH barrier layer 4, and a terminal post 6. The pipe fitting body includes a plastic outer layer 1 and a plastic inner layer 5, The copper insert 2 is embedded in the pipe fitting body, the EVOH barrier layer 4 is arranged in the middle of the pipe fitting body, between the plastic outer layer 1 and the plastic inner layer 5, and the copper wire 3 is arranged in the pipe fitting body using a pre-wiring process. On the inner surface of the plastic outer layer 1, there are two terminal posts 6, which are respectively arranged at the ends of the outer surface of the plastic outer layer 1, and the copper wire 3 is used as a resistance wire, and the two ends are respectively connected to the two terminal posts 6, The terminal post 6 is connected with an external welding machine, and is used for heating the resistance wire, the...

Embodiment 2

[0040] On the basis of embodiment 1, the preparation method of the described electrofusion pipe with barrier effect comprises the following steps:

[0041] (1) Put the pre-cast copper insert into the mold, and use the injection molding process to inject the EVOH barrier layer first;

[0042] (2) After the EVOH barrier layer is formed and cooled, put on the mold, and use the pre-wiring process for copper wire wiring;

[0043] (3) Carry out the secondary injection molding process again, this time injecting the plastic inner layer and the plastic outer layer respectively;

[0044] (4) Final forming and cooling to complete the preparation.

[0045] The processing temperature of the injection molding process of the present application is controlled at 165-235°C.

Embodiment 3

[0047] On the basis of Example 1, when using the electrofusion pipe fitting with barrier function, firstly, the surface of the end of the plastic pipe fitting to be connected is pretreated to remove the oxide layer, and the pretreated plastic pipe fitting is inserted into the Into the annular cavity formed by the plastic outer layer and the plastic inner layer at both ends of the electrofusion pipe fitting, until the end of the plastic pipe fitting to be connected touches the EVOH barrier layer, stop inserting, connect the terminals on both sides with the external welding machine, and use It is used to heat the resistance wire of the copper wire to heat the inner wall of the electrofusion pipe fitting, turn on the power supply, set the heating time and cooling time, and use the heat and expansion force generated when the power is turned on to melt and connect the outer wall of the plastic pipe fitting with the electrofusion pipe fitting. At the same time, the EVOH barrier layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com