Laminated slab type concrete shear wall steel bar snap-fit connecting joint and construction method

A concrete shear wall and snap connection technology, applied in the direction of walls, structural elements, building components, etc., can solve problems such as poor effect, and achieve the effects of reliable connection, tight connection and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

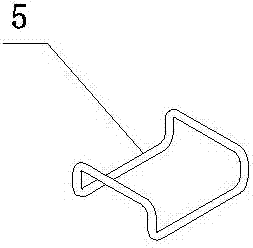

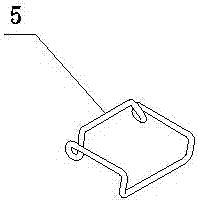

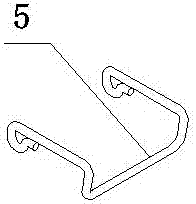

[0033] A kind of fastening connection node of reinforced slab concrete shear wall, which consists of: laminated slab concrete shear wall 1, fastening steel bar 5 and spring bar 6, and the described laminated slab concrete shear wall consists of two layers Concrete thin slabs, and the two thin slabs are formed as a whole by lattice steel bars 2, and the laminated slab concrete shear wall includes longitudinal steel bars 3 and transverse steel bars 4, and the short sides of the transverse steel bars are built with the According to different forms, the fastening steel bar is arranged on the short side of the transverse steel bar in advance and the spring bar is added according to the specific form of the fastening steel bar, so that the spring bar has a reaction force, After the installation of the spring bars is completed, they are fixed with the transverse steel bars by welding.

Embodiment 2

[0035] According to the fastening connection node of the reinforced slab concrete shear wall described in Example 1, the in-situ concrete 7 is cast in the cavity of the mouth of the laminated slab concrete shear wall, and the surface of the thin concrete slab is provided with Operation hole 8.

Embodiment 3

[0037] According to the buckled connection node of the reinforced slab concrete shear wall described in embodiment 1 or 2, the described transverse steel bar is in the form of a ring, and the buckled steel bar is formed into a three-dimensional U-shaped structure and a three-dimensional S-shaped structure by bending. structure, three-dimensional P-type structure and three-dimensional Z-type structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com