Section assembly type pier column structure connection section and design method and construction method thereof

A structural connection and assembly technology, which is applied in the direction of erection/assembly of bridges, bridge construction, construction, etc., can solve the problem of limited application value of segmental assembly piers, high prices of grouting sleeves and special grouting materials, and connection materials. Price increase and other issues, to achieve the effect of reducing processing costs, mechanical continuity of longitudinal ribs, and reducing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

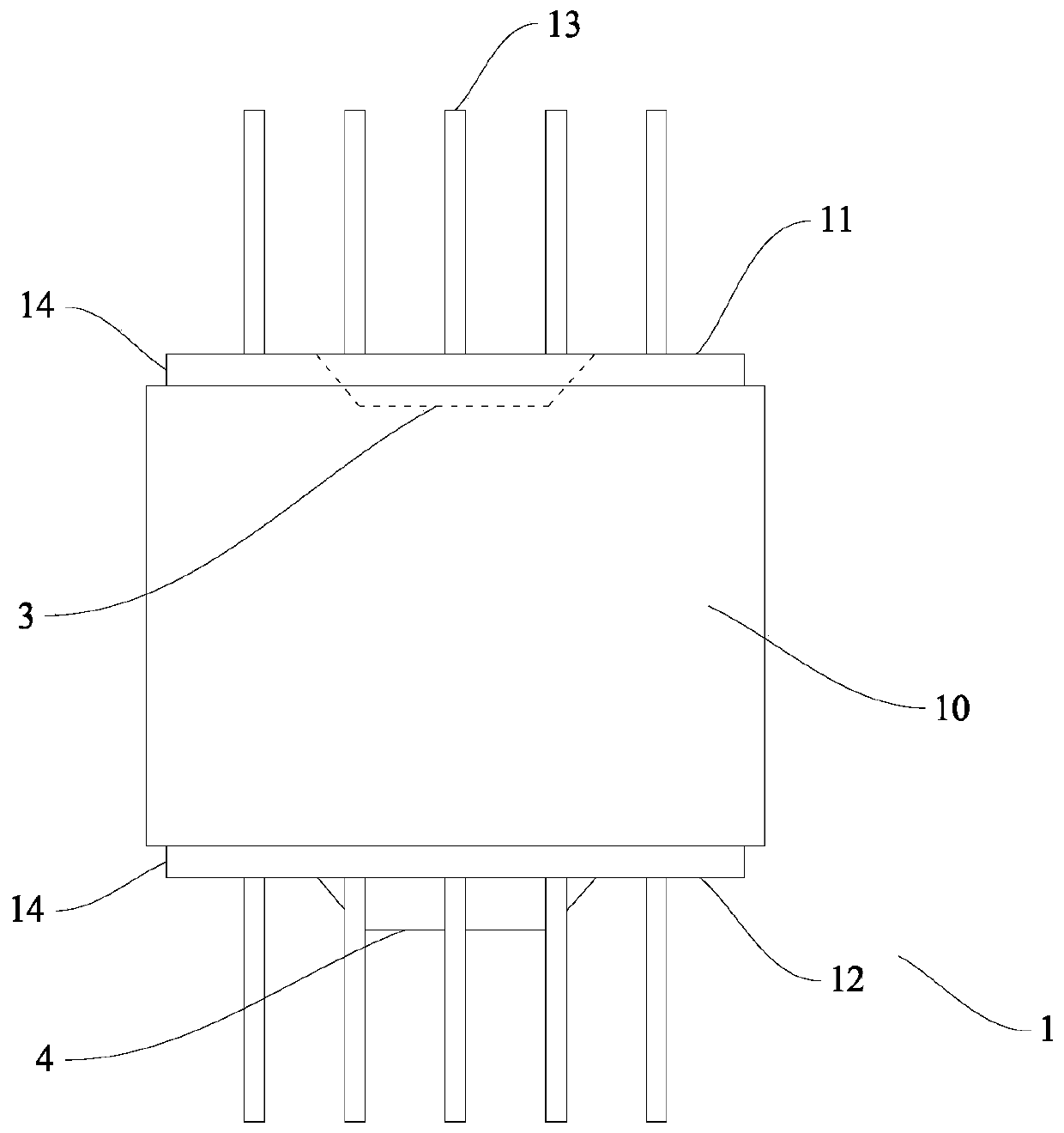

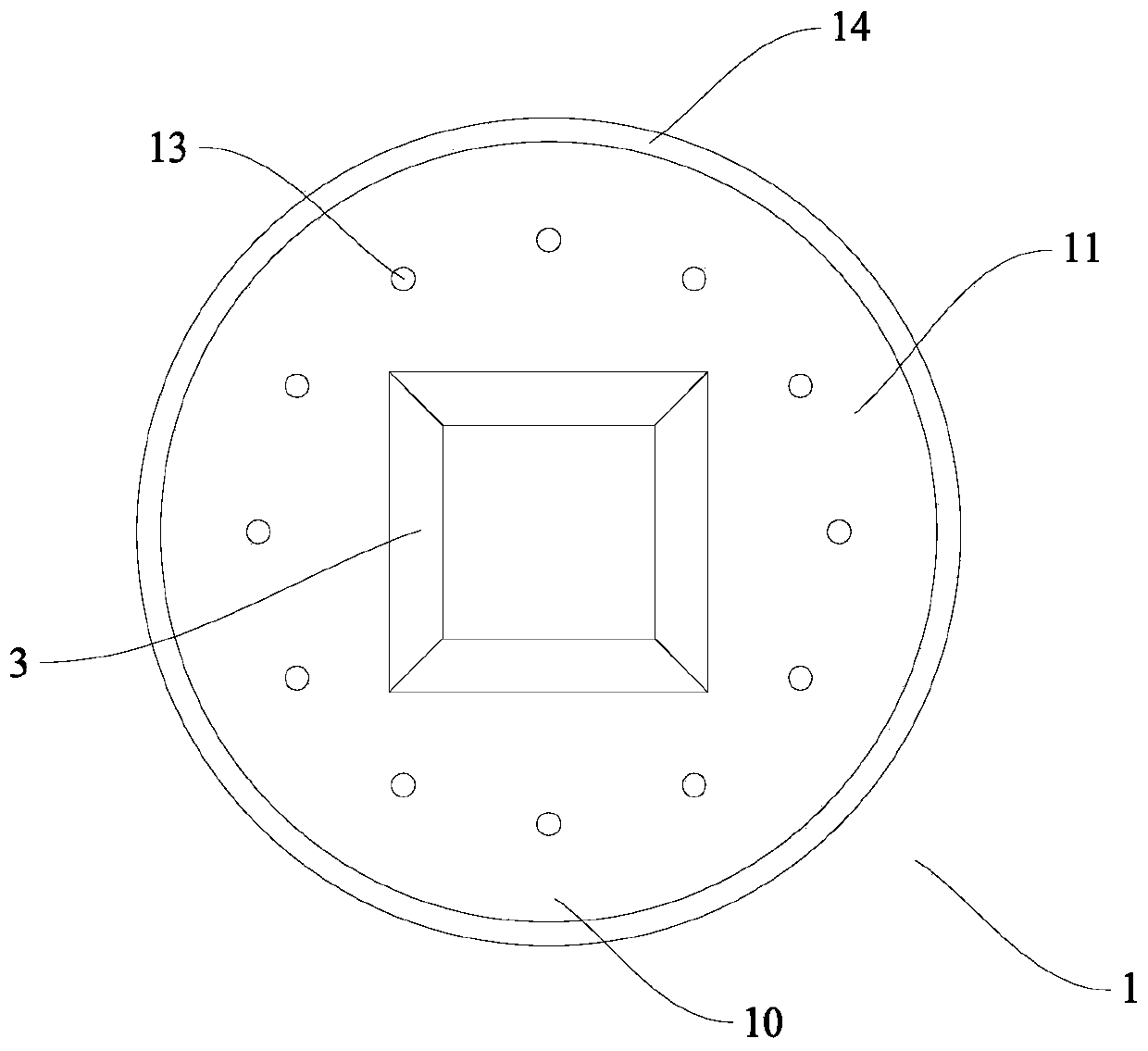

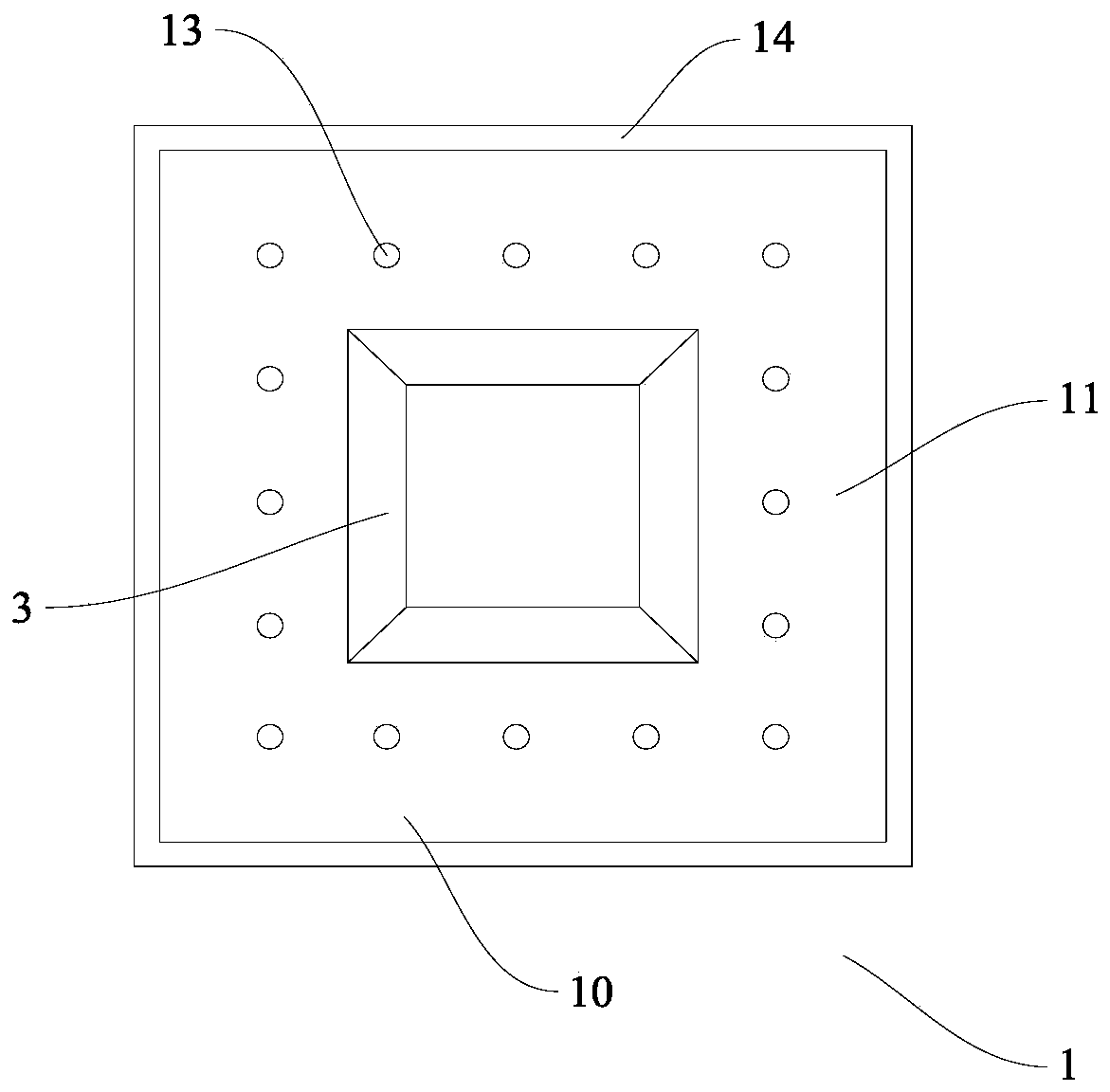

[0066] A structural connection section of a section assembled pier column, comprising a male section 1 and a female section 2 .

[0067] Such as figure 1 As shown, the male segment 1 includes a first body 10, the first body 10 is a reinforced concrete structure, and the body 10 is provided with stirrups. The first body 10 is provided with a first assembly end 11 and a second assembly end 12 , and the first assembly end 11 and the second assembly end 12 are used for assembling with the female segment 2 . Several first longitudinal ribs 13 are also provided in the first body 10, each of the first longitudinal ribs 13 runs through the first body 10, and extends from the first assembly end 11 and the second assembly end 12 respectively. out. In this embodiment, preferably, the length of the first longitudinal rib 13 protruding from the first assembling end 11 is equal to the length protruding from the second assembling end 12 . Such as Figure 2-Figure 3 As shown, the male sec...

Embodiment 2

[0076] A method for designing a structural connection section of a segmentally fabricated pier column, comprising the following steps:

[0077] Step 1: Design the structural connection section of the section-fabricated pier column into two types of standard sections, namely male section 1 and female section 2;

[0078] Step 2: Design the public segment 1, including calculating the cross-sectional size, height, volume reinforcement ratio of the stirrups of the public segment 1, the number, cross-sectional size, and position of the first longitudinal reinforcement 13, and the extension of the first longitudinal reinforcement 13 The length of the first assembling end 11 and the second assembling end 12;

[0079] Step 3: Design the female segment 2, including determining the height of the female segment 2 according to the sum of the lengths of the first longitudinal rib 13 protruding from the first assembly end 11 and the second assembly end 12; according to the number of the firs...

Embodiment 3

[0083] Such as Figure 13-Figure 14 As shown, a construction method for the structural connection section of a segmental fabricated pier column, comprising the following steps:

[0084] Step 1: After the male segment 1 has been assembled, wet the first longitudinal rib 13 of the male segment 1 with tap water, and apply the adhesive material 5 to the first assembly end 11 of the assembled male segment 1, moisten and Level the chiseled surface, and ensure that the shear key A 3 of the male segment 1 is filled with an adhesive material 5 (high-strength mortar, self-leveling concrete, etc.) that is at least a quarter of the volume of the groove. Next, wet the through hole 23 of the female segment 2 to be assembled with tap water first, hoist the female segment 2 above the male segment 1, and align the fourth assembly end 22 of the female segment 2 with the male segment 1, assemble the through hole 23 of the female segment 2 to the first longitudinal rib 13 of the male segment 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com