A method for reinforcing bridge members using polyurethane cement composite material and steel mesh

A cement composite material and polyurethane technology, which is used in bridges, bridge materials, bridge maintenance, etc., can solve the problems of inability to simultaneously improve the tensile and compressive strength of components, insufficient interface strength, and long construction period, and achieve obvious reinforcement effects. The effect of high bond strength and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

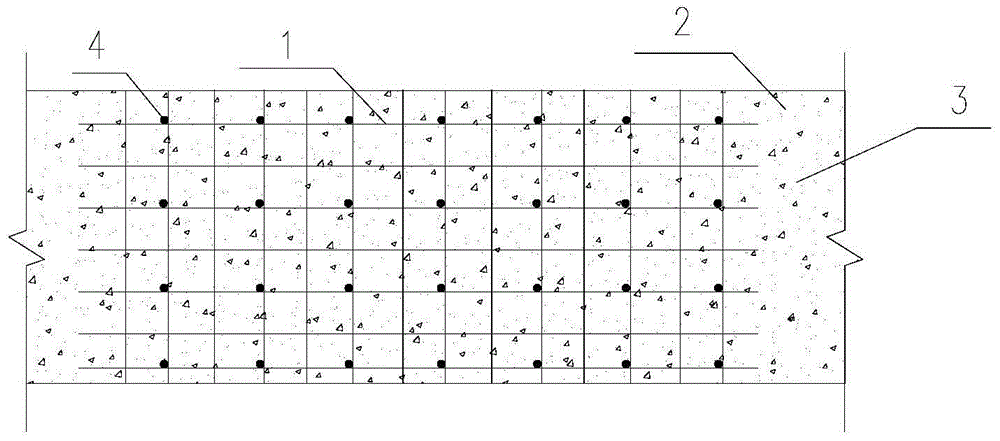

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment in detail, a kind of method that utilizes polyurethane cement composite material and reinforcing bar mesh to strengthen the bridge member described in this embodiment, specifically carry out according to the following steps:

[0017] 1. On the surface of the maintenance and reinforcement parts of the bridge concrete structural components, a rough surface with a difference of unevenness greater than or equal to 6mm is chiseled, the surface of the bridge components is cleaned, and the maintenance and reinforcement parts of the bridge concrete structural components are dried;

[0018] 2. Implant connecting steel bars in the maintenance and reinforcement parts of bridge concrete structural members, hang steel mesh pieces on the connecting steel bars, and weld the steel mesh pieces and connecting steel bars at the same time;

[0019] The steel mesh sheet is a rectangular mesh welded by steel bars wit...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, when the reinforcing bars of the maintenance and reinforcement parts of the bridge concrete structural members are corroded, the surface of the reinforcing bars should be derusted, degreased and polished to reveal metallic luster; When the cross-sectional area caused by the corrosion of the reinforcement is weakened to more than 1 / 10 of the original cross-section, the reinforcement should be supplemented; when the repair and reinforcement of the concrete structural members of the bridge has honeycomb pitting and the concrete falls off, the damaged part should be repaired locally; when the bridge concrete structure Grouting or sealing treatment should be carried out when the cracks in the component repair and reinforcement parts exist. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the connecting steel bars described in step 2 are ordinary steel bars or bolted anchor bars. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com