Segment longitudinal seam connecting assembly, tunnel segment structure and construction method

A technology for connecting components and tunnel segments, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as unreasonable force, segment cracking, waste materials, etc., to ensure reliable connections, improve tolerance capabilities, The effect of expanding the range of activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

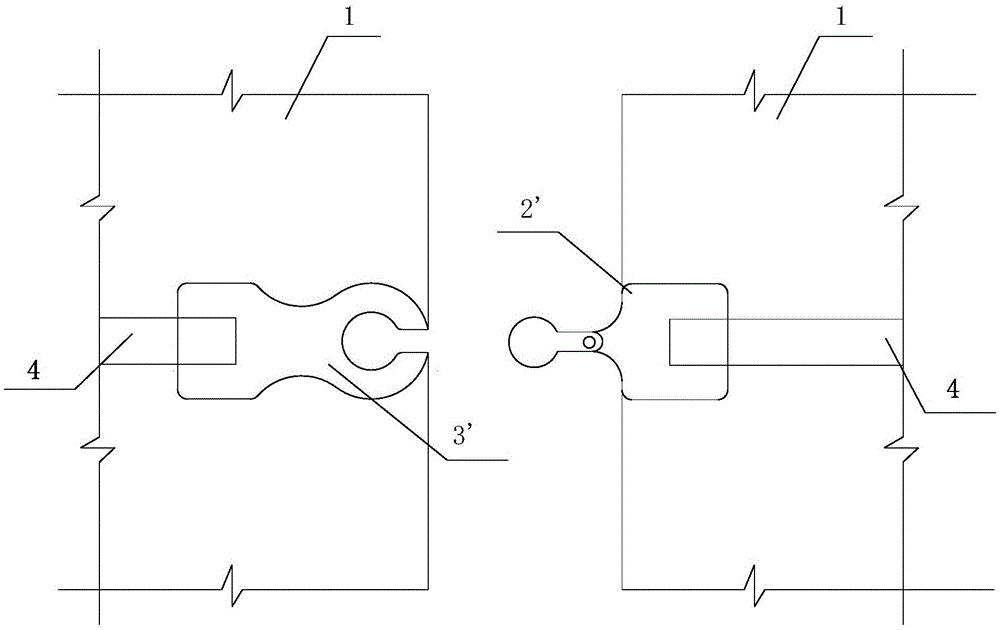

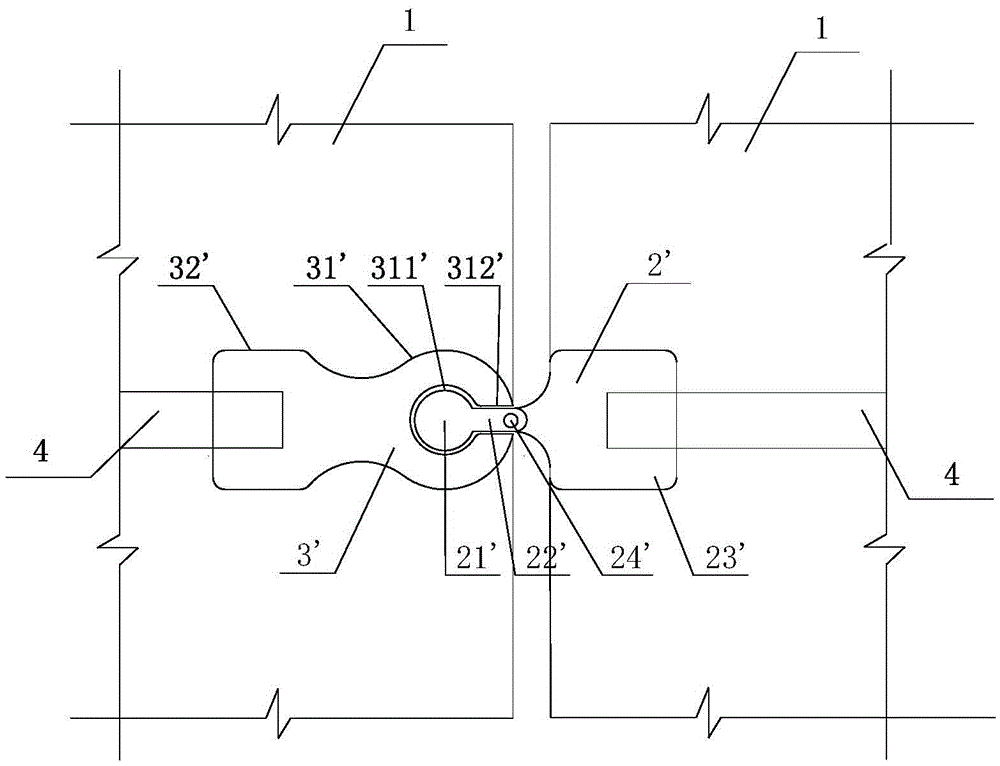

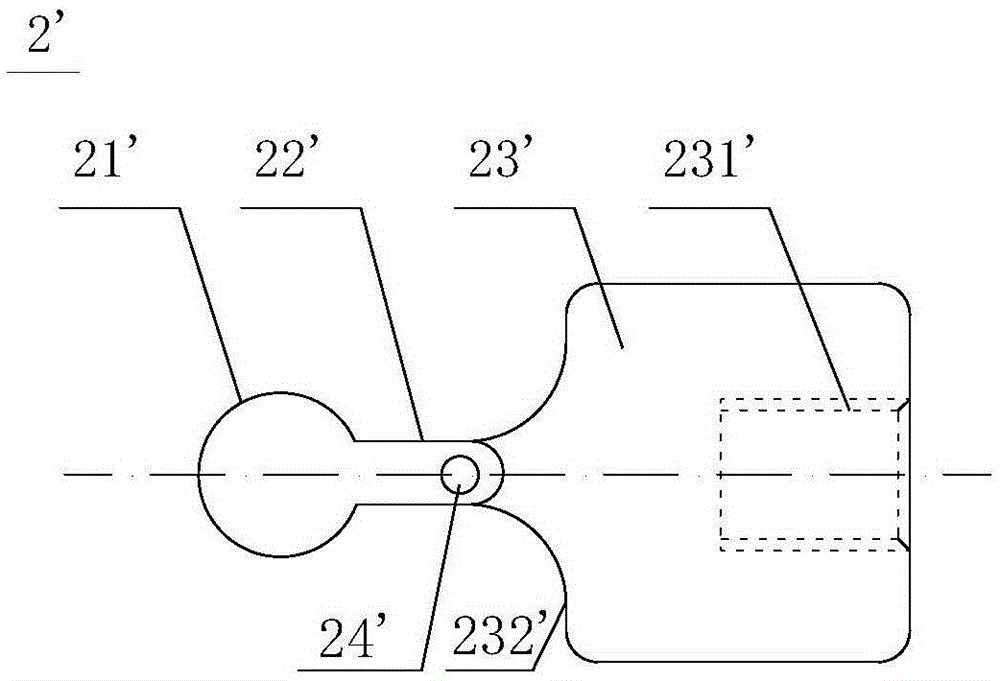

[0054] see Figure 1 to Figure 10 , this embodiment discloses a segment longitudinal seam connection assembly, including a longitudinal seam male part 2' and a longitudinal seam female part 3' respectively pre-embedded on two segments 1 that need to be butted in the circumferential direction, the longitudinal seam The female part 2' and the male part 3 of the circular seam are located on the adjacent end faces of the same segment 1, and the male part 2' of the longitudinal seam includes a cylindrical body 21' with a gradual cross section, a connecting plate 22' and a base 23', and the connecting plate One end of 22' is affixed to the side of the cylinder with gradual cross section 21', the other end of the connecting plate 22' is connected to the base 23', and the thickness of the connecting plate 22' is smaller than that of the cylindrical body with gradual cross section The small head diameter of 21', the axis line of the gradual cross-section cylinder 21' is parallel to the...

Embodiment 2

[0062] This embodiment discloses a tunnel segment structure, including several segments, the segments are connected in the circumferential direction through the segment longitudinal seam connection assembly as described above, and the segments are connected in the longitudinal direction through the segment annular seam connection assembly connect.

[0063] see Figure 11 to Figure 16 , and see in conjunction with Figure 1 to Figure 10, the segment annular seam connection assembly, including the annular seam male part 2 and the annular seam female part 3 respectively pre-embedded on the two segments 1 that need longitudinal butt joint, the longitudinal seam female part 3' and the annular seam male part 2 is located on the adjacent end face of the same segment 1; the female part 2' of the longitudinal seam and the male part 3 of the circular seam are located on the adjacent end face of the same segment 1; the male part 2 of the circular seam includes successively connected hea...

Embodiment 3

[0074] This embodiment discloses a construction method for a tunnel segment structure as described in Embodiment 2, which includes the following steps:

[0075] Step 1: See Figure 17 , and please combine Figure 1 to Figure 16 , use a crane to adjust the position of the segment 1 with the female part 3' and the male part 2 with the longitudinal seam through the segment installation arm 5, so that the groove 10 is aligned with the installed male part 2 with the longitudinal seam 'The longitudinal seam male part 2' of the segment 1, the annular seam male part 2 is aligned with the annular seam female part 3 of another segment having the annular seam female part 3 already installed.

[0076] In the second step, see Figure 18 , and please combine Figure 1 to Figure 16 , through the segment installation arm 5, the segment 1 with the longitudinal seam female part 3' and the annular seam male part 2 is gradually moved along the longitudinal direction of the tunnel to the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com