Connecting piece for splicing of floors

A technology for connecting parts and floors, applied in the direction of floors, buildings, building structures, etc., can solve the problems of troublesome movements, damage to the integrity of the floor, splicing firmness, large deformation range, etc., and achieve the effect of strong bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings.

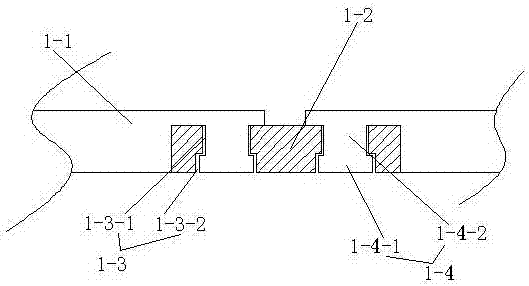

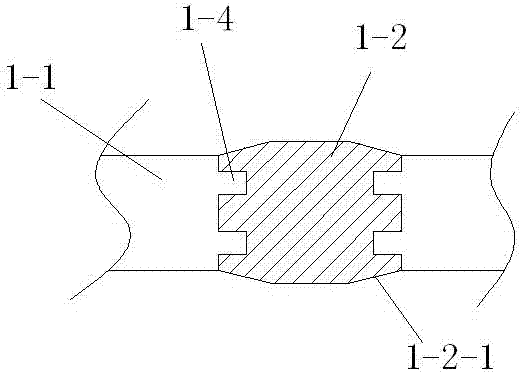

[0019] As shown 1 To map 2 As shown, the embodiment of the present invention includes rigid sections provided at both ends 1-1 And the elastic section in the middle 1-2 , Rigid section 1-1 The length is greater than the elastic section 1-2 The length of the elastic section 1-2 Set card hole 1-3 , Rigid section 1-1 One end is provided with a card hole 1-3 Connected latch 1-4 , Set the elastic segment 1-2 Two-stage card hole 1-3 The direction of insertion is the same. Stuck 1-4 Including the chuck at the end 1-4-1 And set in the rigid section 1-1 With card header 1-4-1 Plug 1-4-2 . Kakong 1-3 For through holes, card holes 1-3 Include insert 1-3-1 And snap section 1-3-2 , Buckle section 1-3-2 The aperture is larger than the insertion section 1-3-1 . Plug 1-4-2 The radial section is the direction, the clamp 1-4-1 The radial cross-section is circular. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com