A connector for floor splicing

A technology for connectors and floors, which is applied in the direction of buildings, floors, and building structures, can solve problems such as troublesome movements, unrecoverable seams, and reduced connection effects of metal parts, so as to achieve a firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

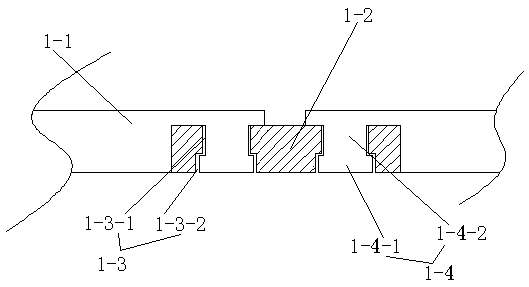

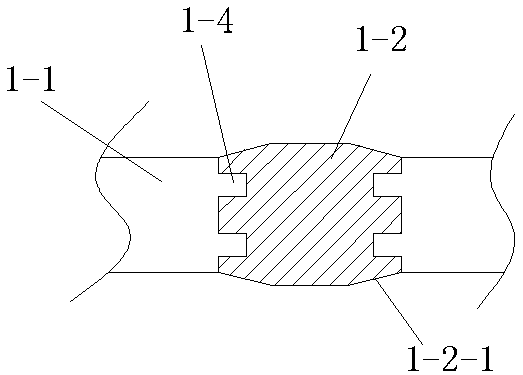

[0019] Such as Figure 1 to Figure 2 As shown, the embodiment of the present invention includes a rigid section 1-1 arranged at both ends and an elastic section 1-2 arranged in the middle, the length of the rigid section 1-1 is greater than the length of the elastic section 1-2, and the elastic section 1-2 is set As for the locking hole 1-3, one end of the rigid section 1-1 is provided with a locking bolt 1-4 connected to the locking hole 1-3, and the insertion directions of the locking holes 1-3 arranged at both ends of the elastic section 1-2 are the same. The clamp 1-4 includes a clamp head 1-4-1 disposed at the end and a clamp body 1-4-2 disposed between the rigid section 1-1 and the clamp head 1-4-1. The clamping hole 1-3 is a through hole, and the clamping hole 1-3 includes an insertion section 1-3-1 and a buckle section 1-3-2, and the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com